A kind of ship safety hatch cover

A technology for safe cabins and ships, which is applied in the direction of ship hatches/hatches, ship construction, ship parts, etc. It can solve problems such as increased wear, difficulty in opening the hatch cover, and affecting the service life of the hatch cover, so as to prevent corrosion and facilitate passage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

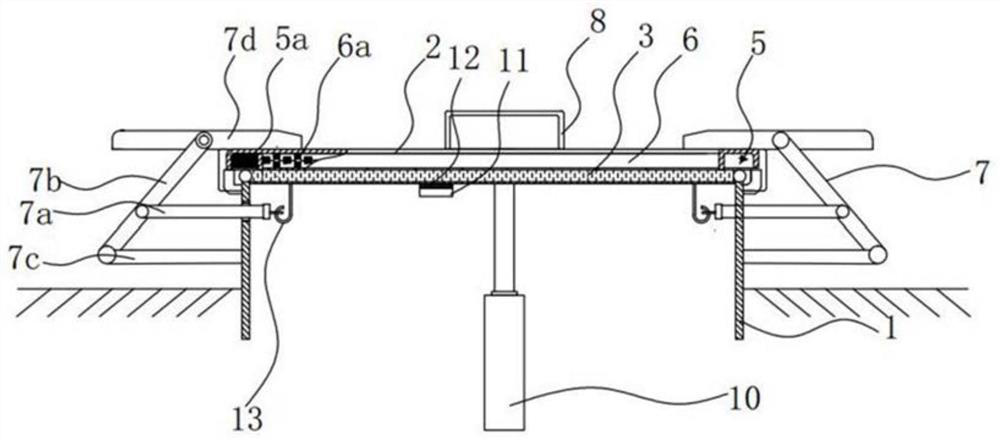

[0025] Combined with the following Figure 1-8 , the present invention is described in detail.

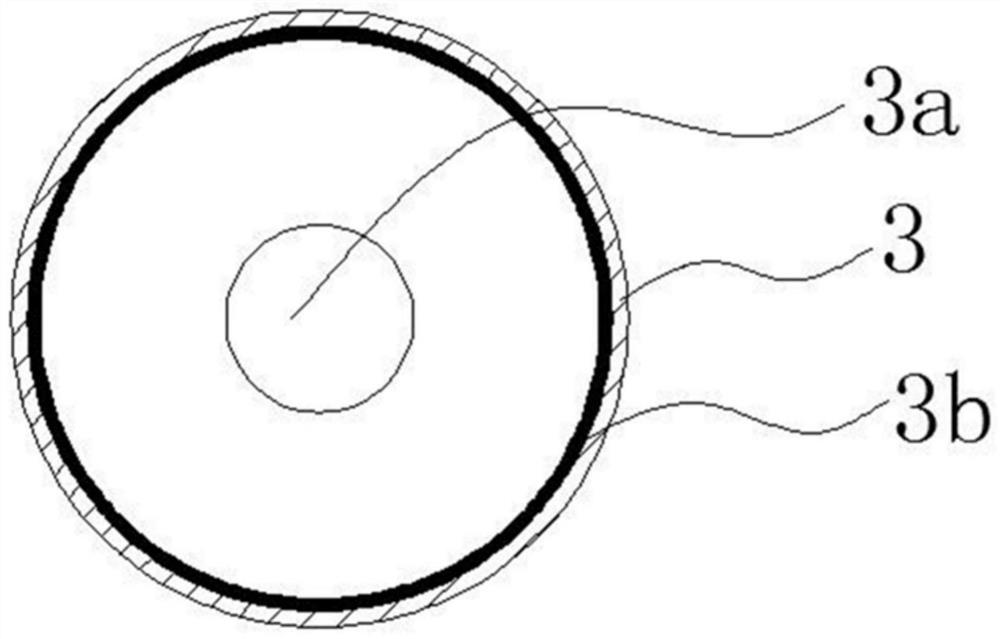

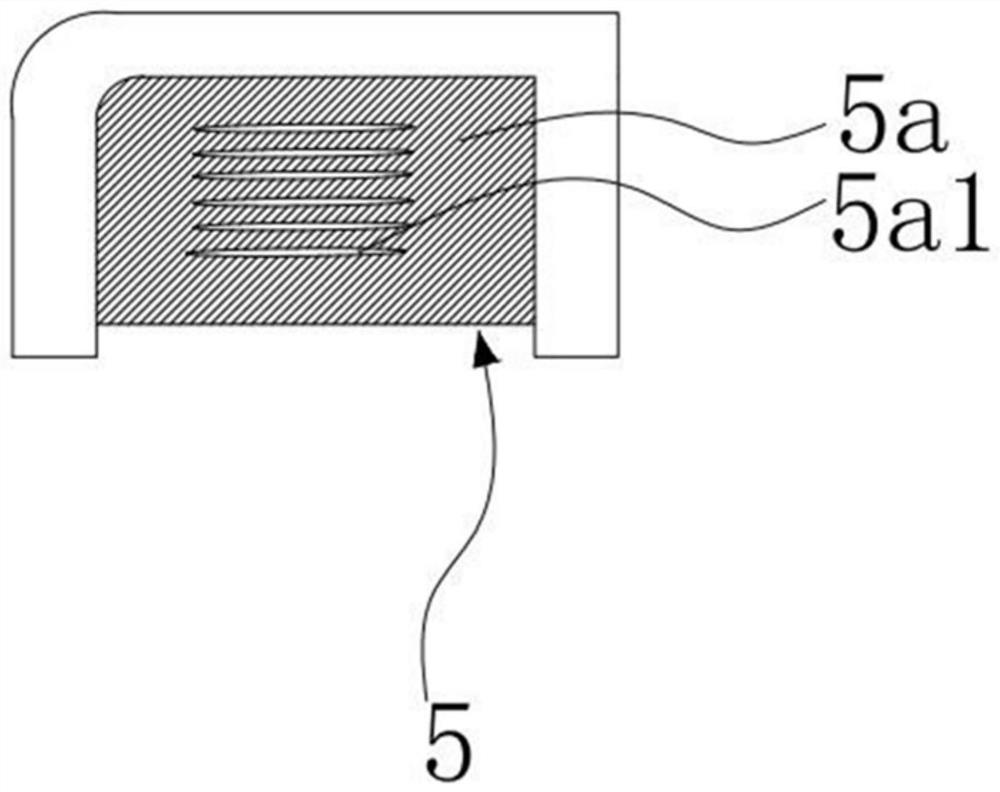

[0026] A safety hatch cover 2 for a ship, comprising: a coaming plate 1, a hatch cover 2 is detachably arranged on the coaming plate 1, an assembly pipe 3 is arranged on the inner wall of the hatch cover 2, and an electric heating wire 3a is threaded inside the assembly pipe 3 , the inner wall of the assembly pipe 3 is wrapped with a heat-conducting insulator 3b, the outer wall of the coaming 1 is fixed with an electric heater 4, the electric heater 4 is electrically connected to the electric heating wire 3a, and the four sides of the hatch cover 2 are provided with sealing grooves 5, and the sealing groove 5 is connected to the The upper wall of the coaming plate 1 is arranged in cooperation, and the sealing block 5a is arranged in the sealing groove 5, and the heat insulating hollow layer 6 is arranged between the sealing grooves 5, and the heat insulating hollow layer 6 is fille...

Embodiment 2

[0035] When the personnel needs to open the hatch cover 2, pull the pull ring 7a1 to make the pull ring 7a1 break away from the hook 13, and the moving block 7d3 breaks away from the limit groove 7d1 during the pulling process. At this time, the button 11 is pressed, and the force sensing device 12 feels the force. When the preset value is pressed, it means that the insider intends to open the hatch cover 2, and the force sensing device 12 starts the electric control hydraulic rod 10 to rise. At this time, the hatch cover 2 is lifted and the rotating mechanism 9 is rotated, and the hatch cover 2 is opened. When the locking mechanism 7 is fully opened, the limiting block 7a2 just abuts against the inner wall of the coaming plate 1, and the limiting block 7a2 prevents the control rod 7a from moving outwards, so that the locking mechanism 7 remains in an open state. After entering the manhole, when the cover plate needs to be locked tightly, pull the pull ring 7a1, and the locking...

Embodiment 3

[0037] According to attached Figure 1-9 , the vertical distance from the fulcrum of the fixed rod 7c and the moving rod 7b to the outer surface of the enclosure 1 is L1, the distance between the fulcrum of the fixed rod 7c and the moving rod 7b and the fulcrum of the control rod 7a and the moving rod 7b is L2, and the control rod 7a and the distance between the fulcrum of the moving rod 7b and the moving block 7d3 is L3, wherein in this embodiment, L1 / L2 / L3 / =2 / 0.8 / 1.4, when the locking mechanism 7 is in the locked state, the moving The rod can obtain a large instantaneous force, so that the moving block 7d3 can quickly break away from the limit groove 7d2, so as to ensure that the hatch can be opened safely and smoothly, and protect the safety of personnel; The moving rod 7b obtains a large acceleration, which accelerates the locking block 9d to reach the locked state, which is conducive to the fast locking of the hatch cover 2 in an emergency and protects the safety of perso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com