A device for brushing oil on the inner surface of a Roman column mold

A Roman column and mold-in-mold technology, which is applied in the field of oil brushing device on the inner surface of the Roman column mold, can solve the problems of uneven oil brushing, slow speed, etc., and achieve the effect of improving the quality of oil brushing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

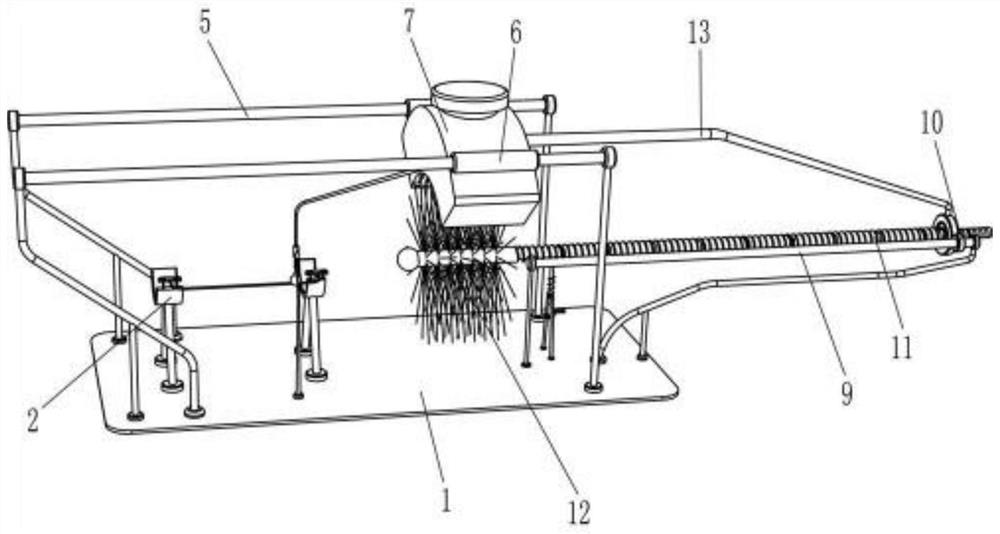

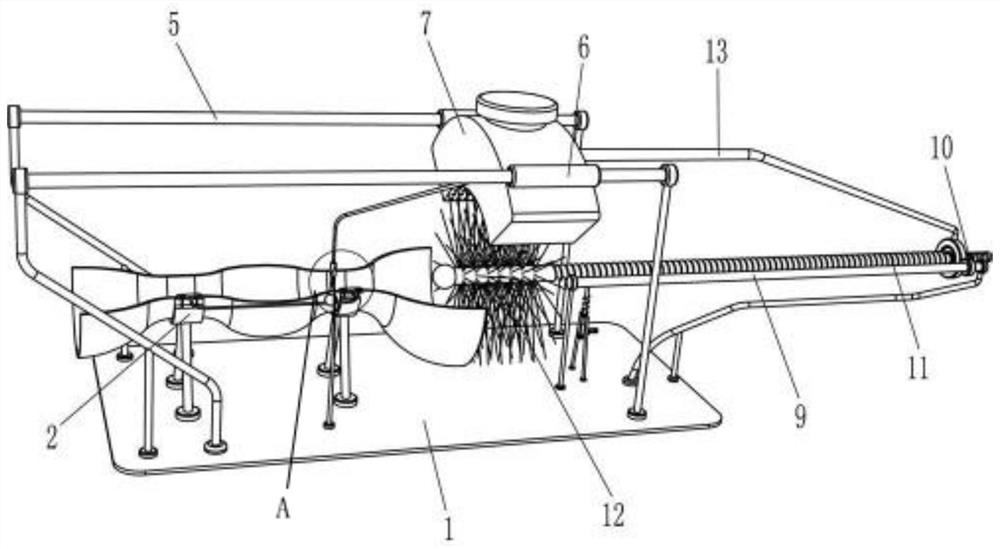

[0025] A kind of Roman column mold inner surface brushing device, such as Figure 1-5 As shown, it includes a mounting frame 1, a placement component, an oil storage component and an oil brushing component. The upper left part of the mounting frame 1 is provided with a placement component for placing the Roman column mold, and the mounting frame 1 is provided with an oil storage component for storing oil. , The upper right part of the mounting frame 1 is provided with a brushing assembly for brushing oil by rotating.

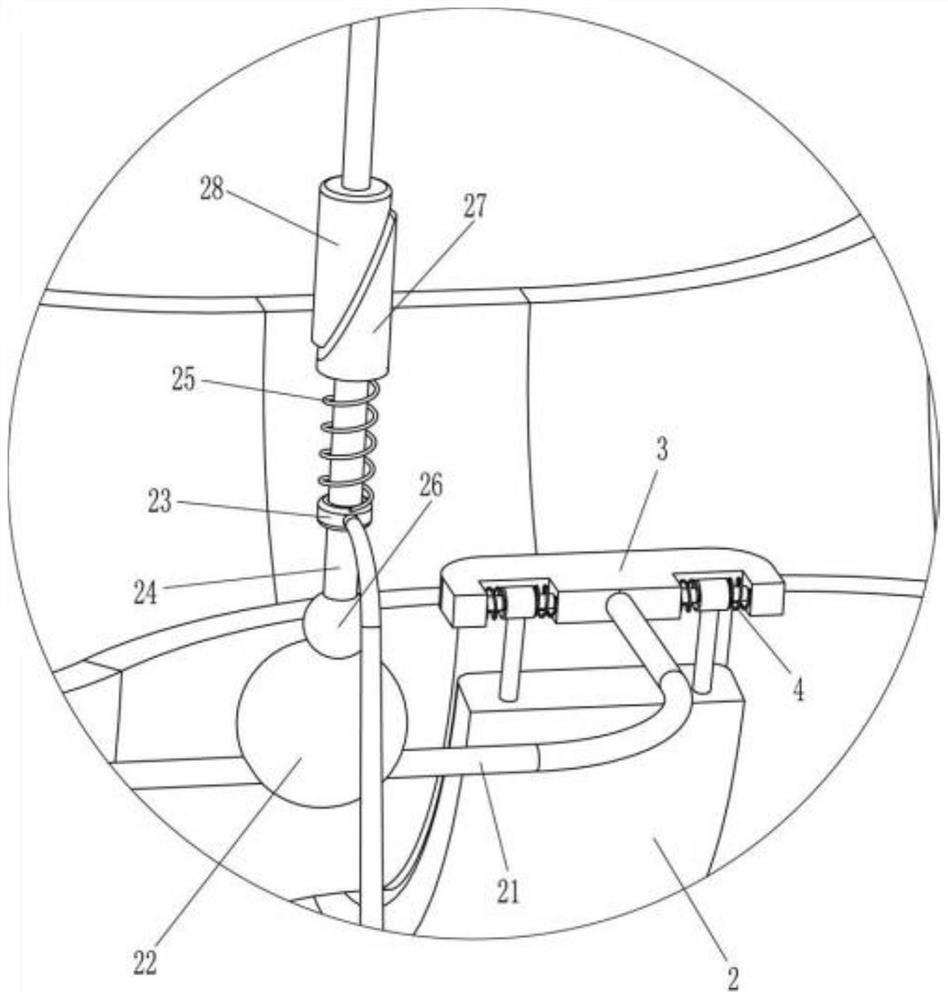

[0026] Such as image 3 As shown, the placement assembly includes an arc-shaped placement plate 2, a fixed plate 3 and a torsion spring 4. The left and right sides of the top of the installation frame 1 are symmetrically provided with an arc-shaped placement plate 2, and the top and front side of the arc-shaped placement plate 2 is rotated. The fixed plate 3 is connected with a torsion spring 4 between the fixed plate 3 and the installation frame 1 .

[0027] ...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 5 As shown, it also includes a second guide sleeve 17, an insertion rod 18 and a second spring 19, the right side of the bottom of the first guide sleeve 14 is provided with a second guide sleeve 17, and the second guide sleeve 17 is slidingly provided with an insertion rod 18 , A second spring 19 is connected between the insertion rod 18 and the second guide sleeve 17 , two through holes 20 are opened on the first slide rod 15 , and the insertion rod 18 cooperates with the through holes 20 .

[0035] Such as image 3 As shown, it also includes a U-shaped connecting rod 21, a projection 22, a third guide sleeve 23, a second slide bar 24, a third spring 25, a push block 26, a first wedge block 27 and a second wedge block 28, both A U-shaped connecting rod 21 is arranged between the side fixing plates 3, and the right part of the U-shaped connecting rod 21 is provided with a projection 22, and the left front part of the mounting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap