Cosmetic filling auxiliary device better in filling effect through limiting and vibration

An auxiliary device and cosmetic technology, applied in packaging, liquid bottling, bottle filling, etc., can solve the problems of material overflow, material waste, uneven material distribution, etc., and achieve the effect of increasing linkage and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

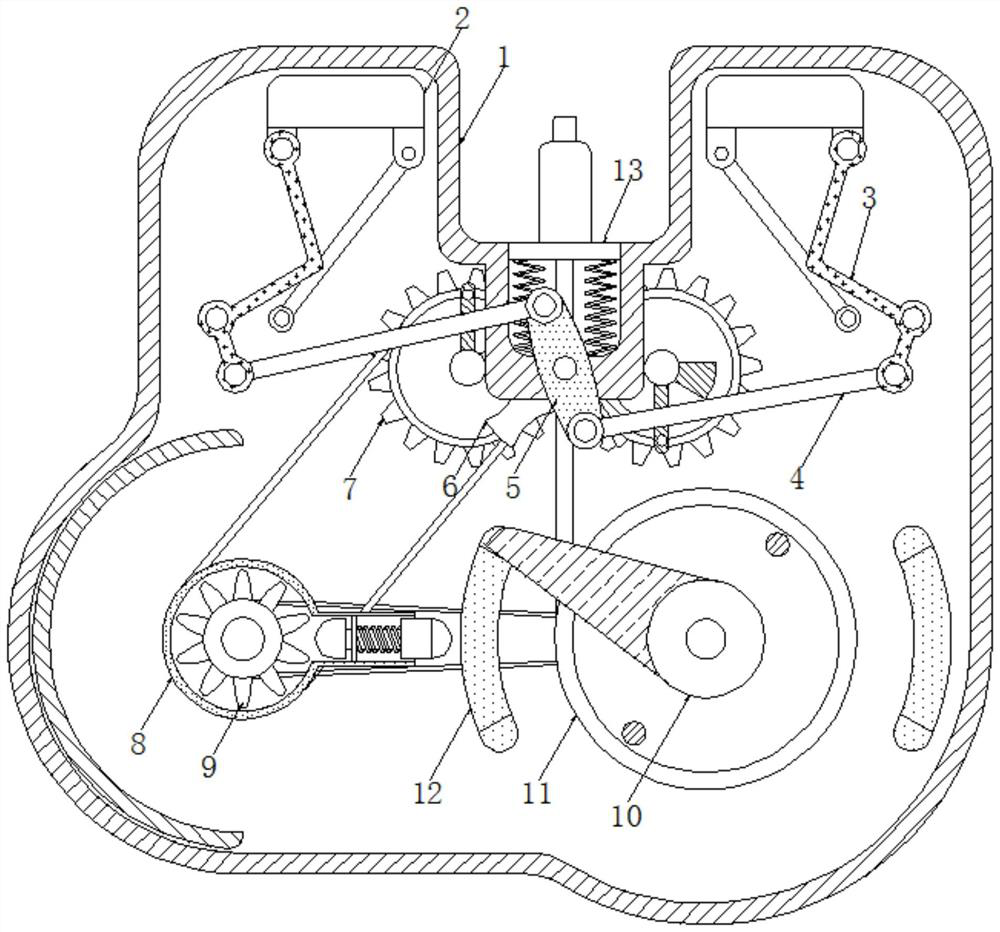

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

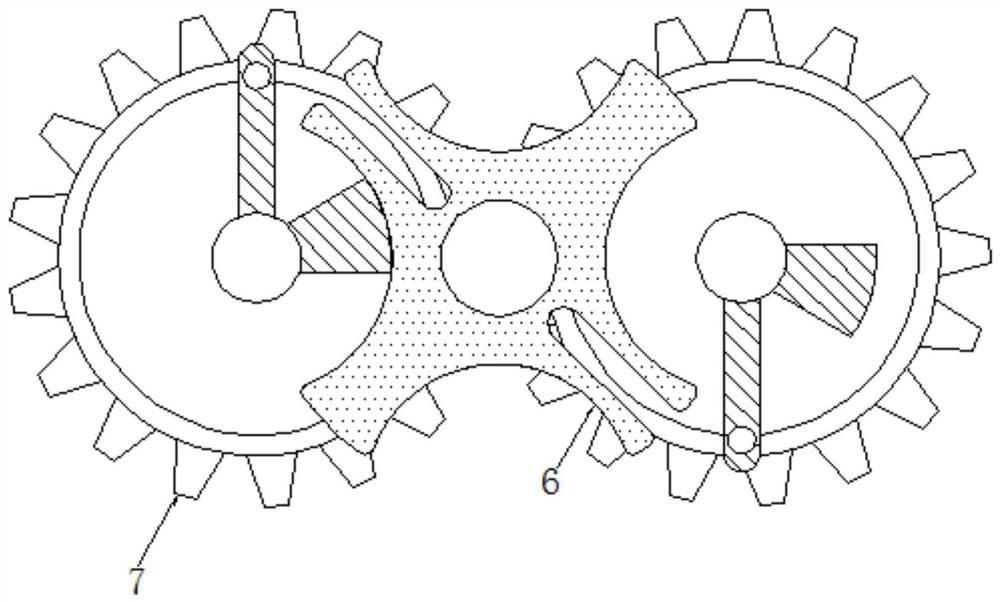

[0022] See Figure 1-4 , An auxiliary device for cosmetics filling that limits and vibrates to make the filling effect better. It includes a shell 1, an internal movable connection limit block 2 of the shell 1, two limit blocks 2 and the same size, two limit blocks Position blocks 2 are located on both sides of the placement plate 13 and are symmetrically distributed with the central axis of the placement plate 13 as a reference. Initial...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap