Quilting machine with double layers of material frames

A technology of quilting machine and material frame, applied in the field of quilting machine, can solve the problems of low production efficiency, waste of time for material change and placement, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

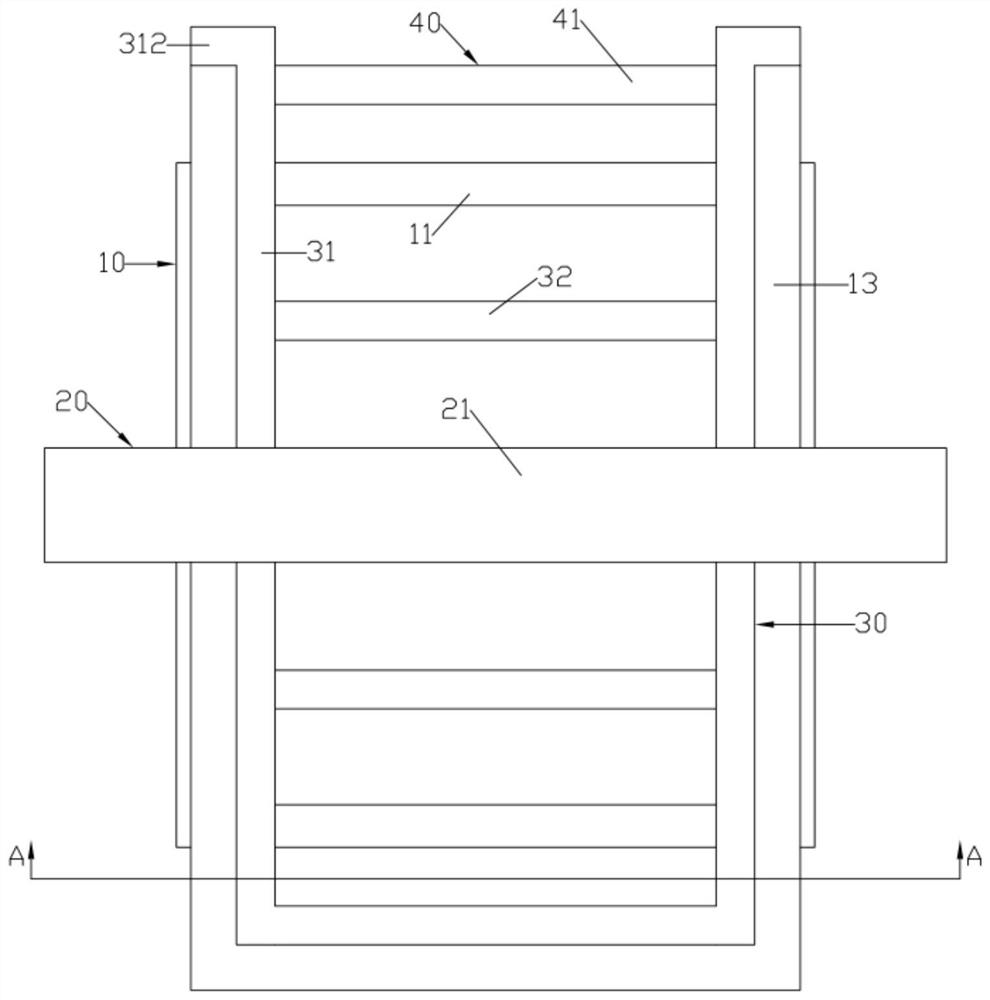

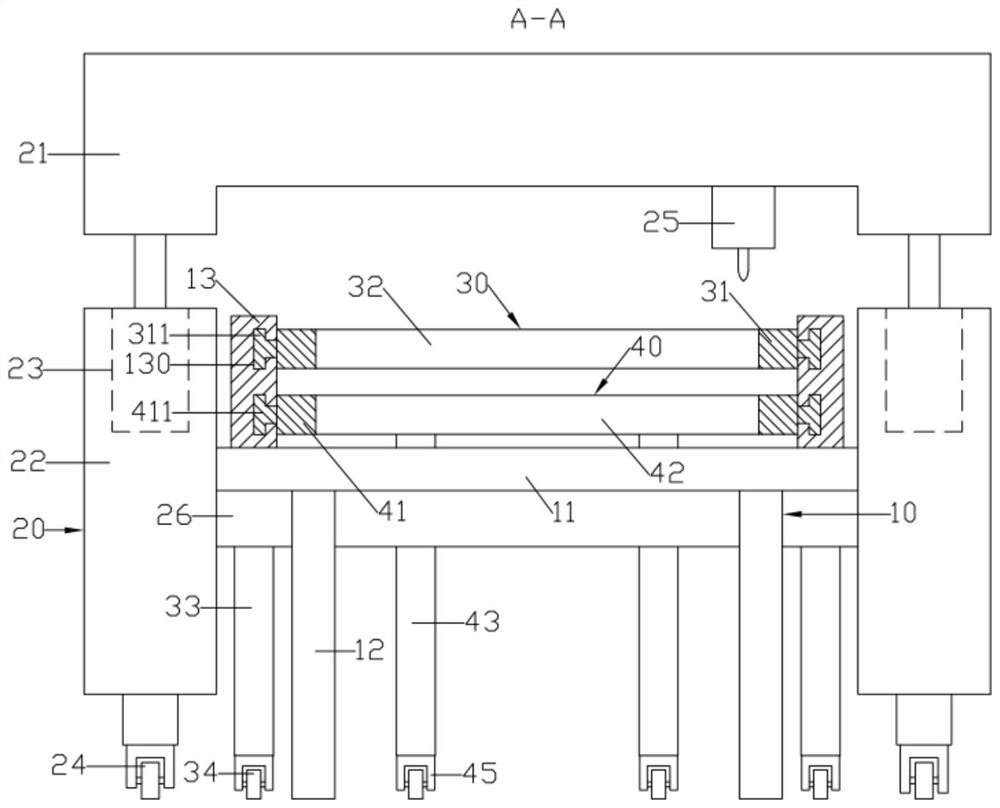

[0015] like figure 1 and figure 2 As shown, a quilting machine with a double-layer material frame includes a bracket 10, a quilting unit 20 and a moving material rack 30; the bracket 10 includes a rectangular frame-shaped upper support frame 11; a pair of lateral parts of the upper support frame 11 A pair of left-right symmetrical support feet 12 are respectively formed on the lower end surface of the bottom surface; the quilting unit 20 includes a "凵"-shaped quilting bracket 21 with the opening facing downward and a pair of left-right symmetrical quilting moving columns 22; The quilting moving column 22 is respectively moved back and forth and arranged on the left and right end surfaces of the upper support frame 11; the quilting bracket 21 is lifted and arranged on a pair of quilting moving columns 22; There is a quilting machine head 25; the upper end surface of the upper support frame 11 is fixed with a mobile support frame 13 in the shape of "凵" with the opening facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com