Closely-arranged rod bundle fuel assembly thermal hydraulic experiment device

A fuel assembly and thermal-hydraulic technology, applied in the field of thermal-hydraulic experimental devices for closely arranged fuel assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

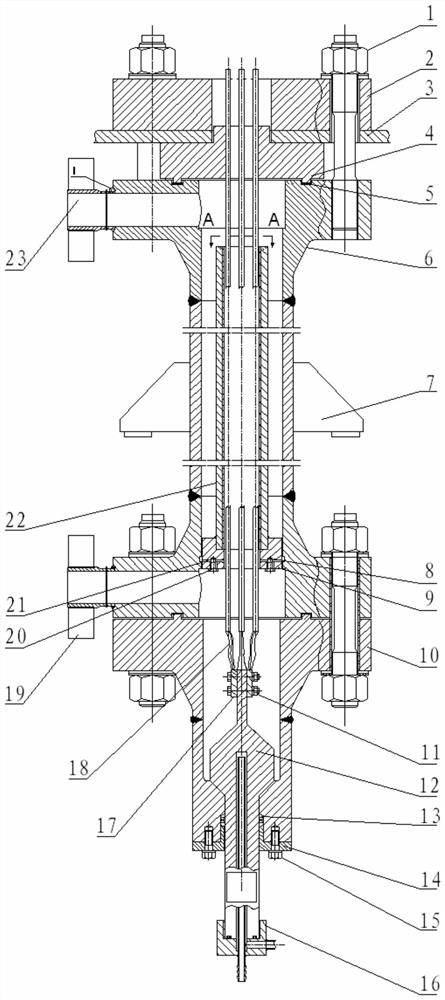

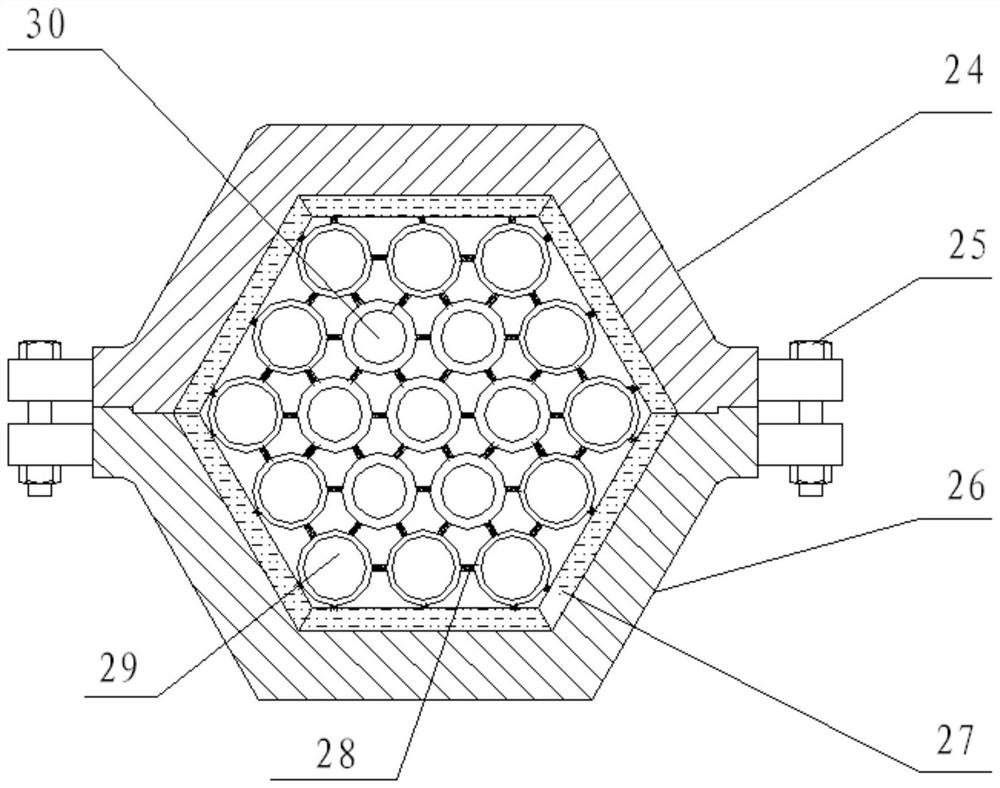

[0051] Such as Figure 1 to Figure 3 As shown, the thermal-hydraulic experimental device for closely arranged rod bundle fuel assemblies includes a pressure-bearing assembly and an electric heating assembly. The pressure-bearing assembly includes a cylinder assembly 6 for providing a pressure boundary, and the electric heating assembly includes a plurality of The element rods of the fuel assembly, the cylinder assembly 6 is also provided with a cold fluid flow channel for providing a fluid boundary, the element rods are arranged at intervals in the cylinder assembly 6, and the element rods are: From one end to the other end, they are copper rod section, stainless steel section and copper rod section;

[0052] On the element rod, the copper rod section at one end is used as the fixed end of the element rod fixed on the pressure-bearing assembly, the copper rod section at the other end is the cantilever end, and the copper rod sections at both ends of the element rod are used as...

Embodiment 2

[0059] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, as a more specific implementation form of the electric heating assembly and the fixing method of the element rod, it is set that: the electric heating assembly also includes a conductive head 4 that is insulated and fixedly connected to the cylinder assembly 6, and the conductive head 4 is provided with The number of holes is equal to the number of component rods, and the relative arrangement is consistent with the relative arrangement of component rods;

[0060] The copper rod section at one end of each component rod is embedded in the hole to form an electrical connection and a fixed connection relationship with the conductive head 4;

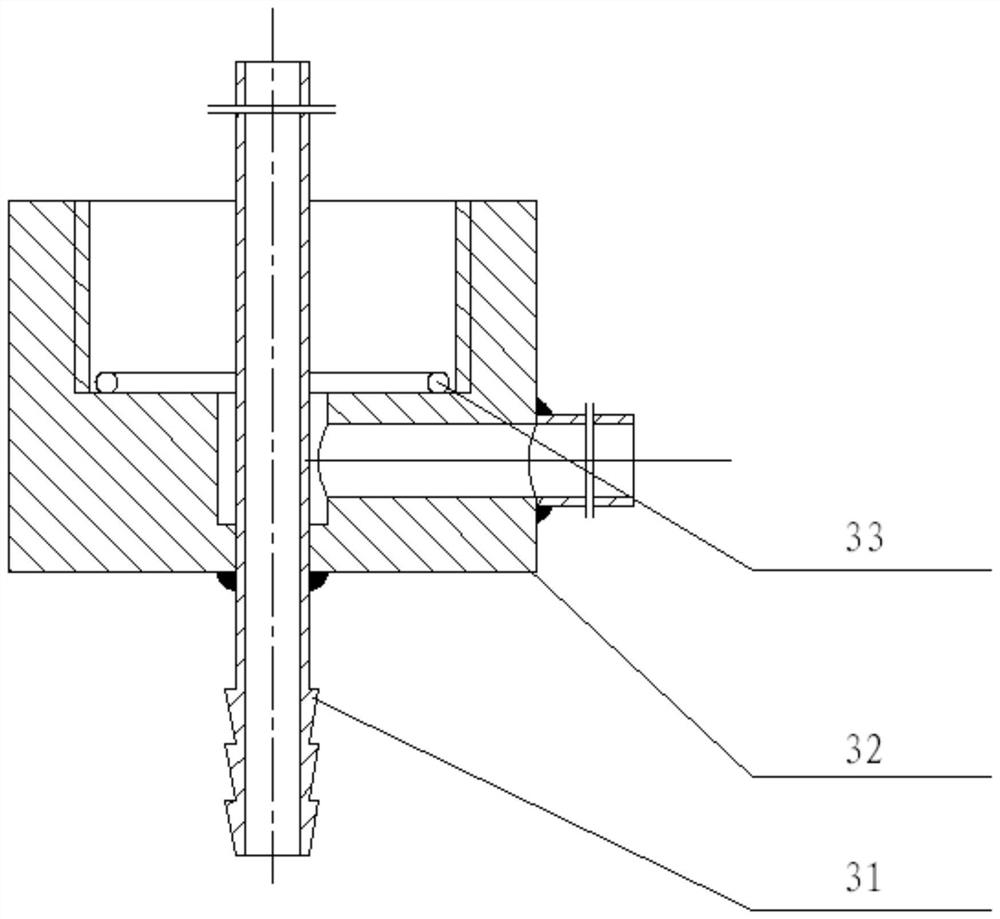

[0061] The electric heating assembly also includes a conductive rod 12 made of copper and fixedly connected to the cylinder assembly 6;

[0062] The conductive head 4 and the conductive rod 12 are located at different ends of the...

Embodiment 3

[0075] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 Shown: As a technical solution for forming the pressure boundary and for forming the boundary of the cold fluid flow channel based on different components to facilitate the design, preparation, installation and versatility of the pressure-bearing components of this experimental device, it is set to: also include fixing The flow channel plate assembly 22 in the barrel assembly 6 is a tubular structure, and the inner space of the flow channel plate assembly 22 serves as part or all of the cold fluid flow channel.

[0076] As a technical solution that facilitates the design of the pressure-bearing component as a tubular container, and the pressure-bearing component has a small structure and high pressure-bearing capacity, and as a technical solution that includes the specific installation form of the flow channel plate component 22, it is set as follows: The axis of the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com