Tubing plug

A technology of tubing plugs and drogue sleeves, which is applied in wellbore/well components, sealing/packing, earthwork drilling and production, etc. It can solve the problems of difficulty and low extraction efficiency of tubing plugs, and achieve the goal of reducing the difficulty of extraction, The effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

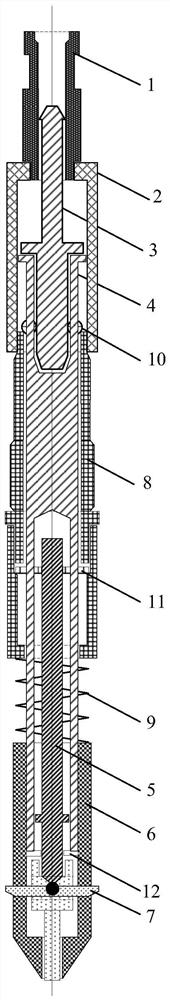

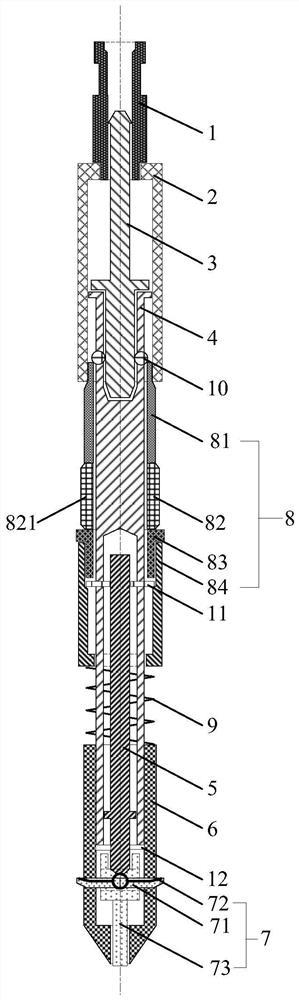

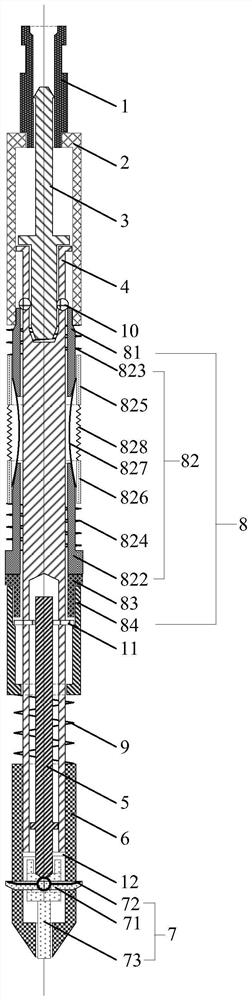

[0037] figure 1 A schematic structural view of an oil pipe plug according to an embodiment of the present invention is shown. as attached figure 1 As shown, the oil pipe plug includes: lifting joint 1, fixed sleeve 2, fishing joint 3, main body 4, limit shaft 5, guide head 6, pawl assembly 7, seat seal assembly 8, spring 9, first The limiting component 10 and the second limiting component 11 .

[0038]The first end of the fixing sleeve 2 is provided with an inversion edge, the first end of the lifting joint 1 is located in the inner cavity of the fixing sleeve 2, and the first end of the lifting joint 1 and the first end of the fixing sleeve 2 are passed through the shear nails. Connection, the first end of the fishing joint 3 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com