Seat seal mechanism used for packing type tail pipe hanger

A liner hanger and packer technology, which is applied to wellbore/well components, earth-moving drilling, etc., can solve the problems of early seating of the packer hanger, etc., so as to facilitate the judgment of throwing hands and prevent early seating. , the effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment, further illustrate the present invention.

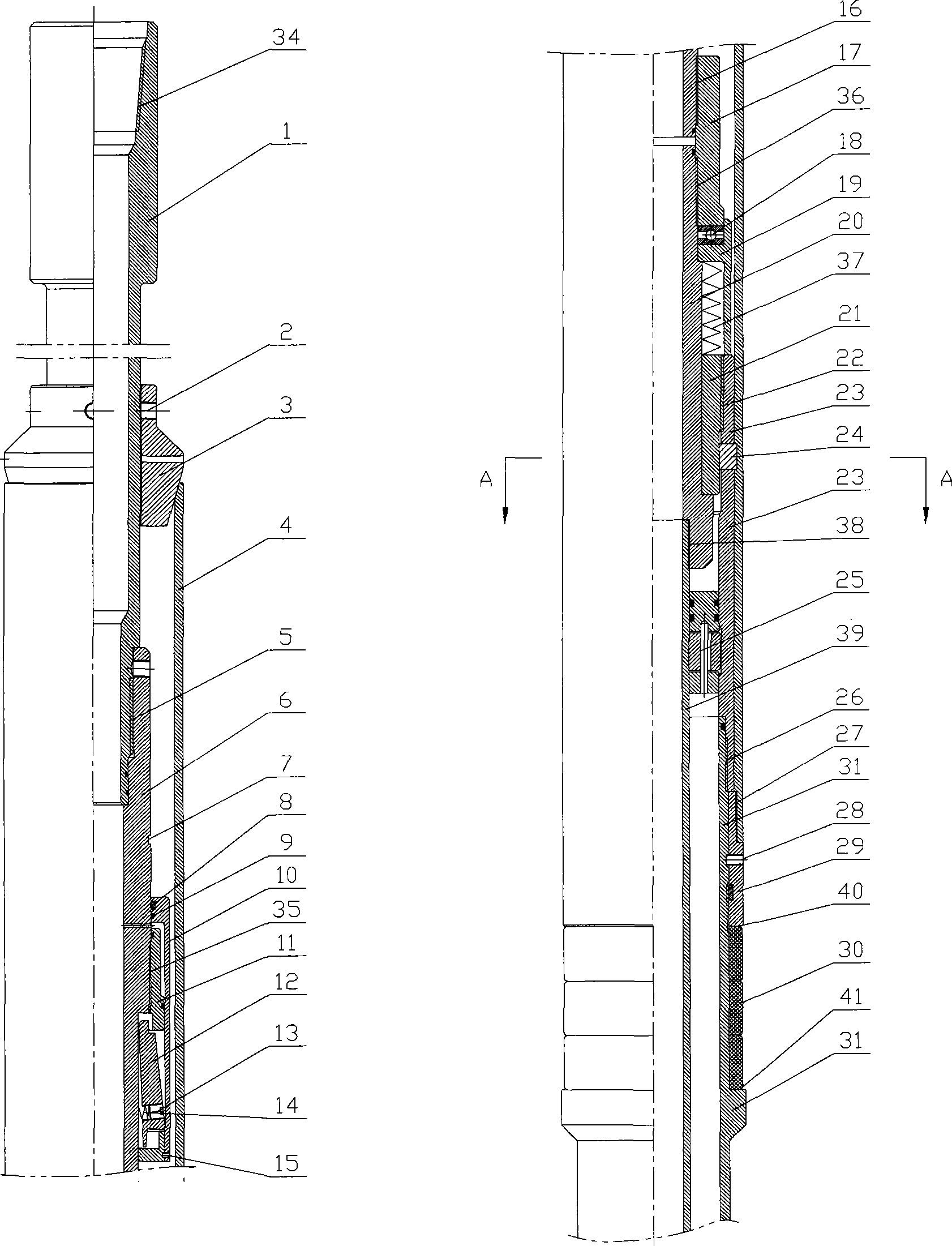

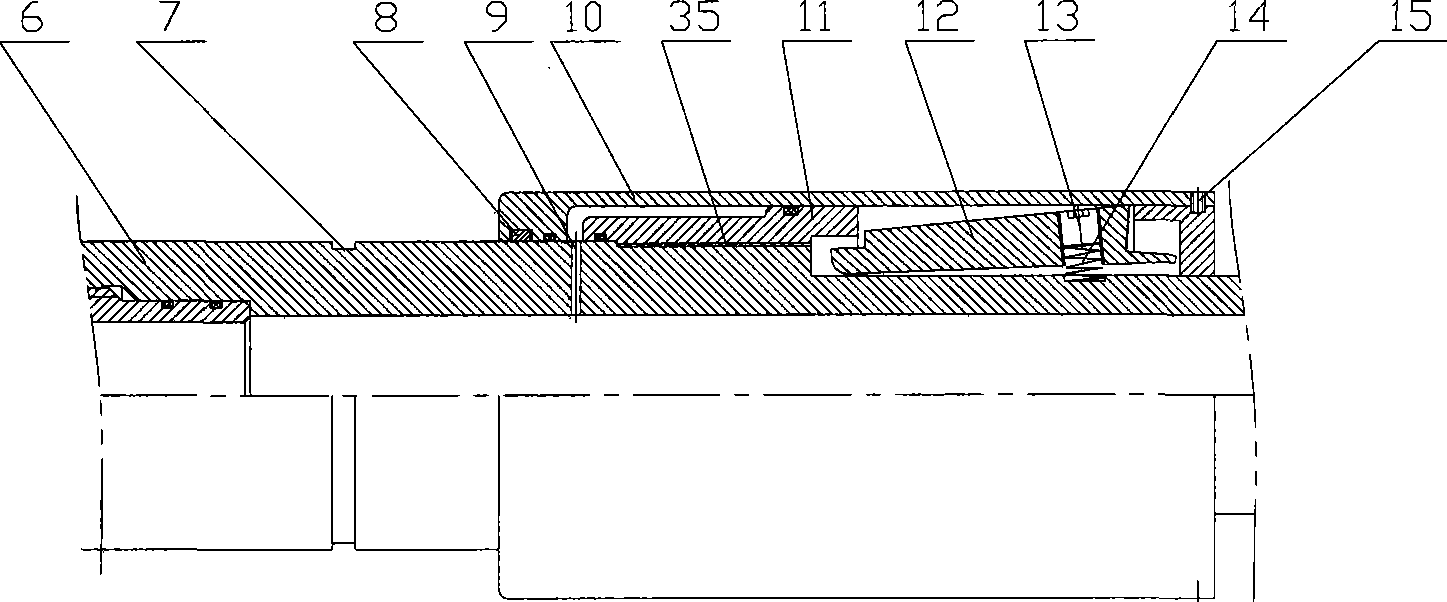

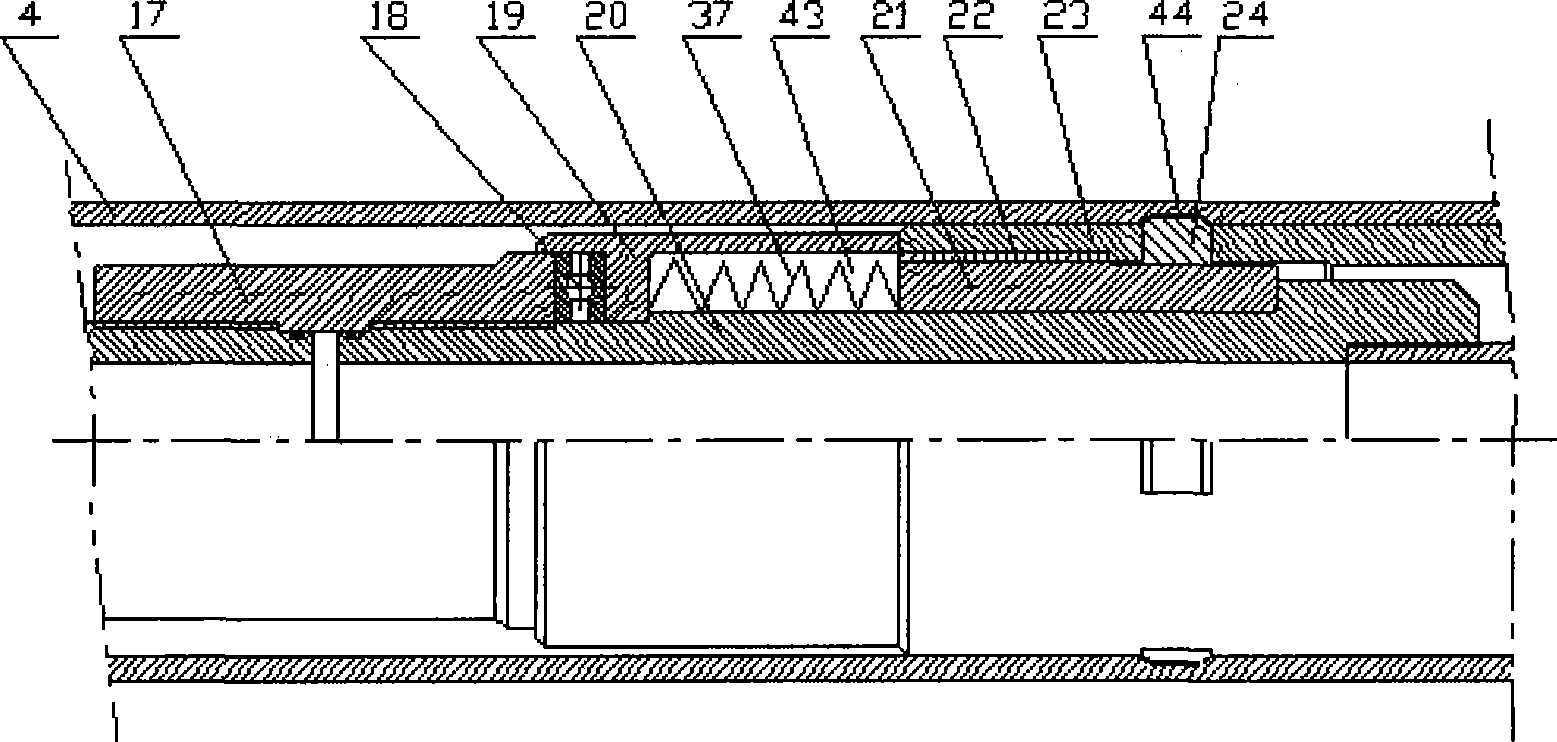

[0041] The purpose of the present invention is to provide a safe and reliable sealing mechanism including a running tool for a sealed hanger. Such as figure 1 As shown, the setting mechanism of the present invention includes a running tool, a sealing shell 23, a tie-back barrel 4, a packer, and the like.

[0042] Wherein, the sealing shell 23 and the tie-back barrel 4 are both cylindrical structures, and the tie-back barrel 4 is sleeved on the outside of the seal shell 23 . Both the upper and lower ends of the connecting barrel 4 protrude from the upper and lower ends of the sealed casing 23 .

[0043] The packer includes a packer body 31 and a seat cover 29 covering the middle of the packer body, both of which are cylindrical structures, and are fixed with packer shears 28 therebetween. A packer rubber cartridge set 30 is installed between the lower end surface 40 of the seat cover 29 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com