Device for salvaging blockage in oil pipe by hydraulically delivering steel wires and using method thereof

A steel wire and hydraulic technology, which is applied in the field of plugging devices in hydraulic wire salvage oil pipes, can solve the problems of plug resistance, oil pipe blockage, slow descending speed, etc. Delivering high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

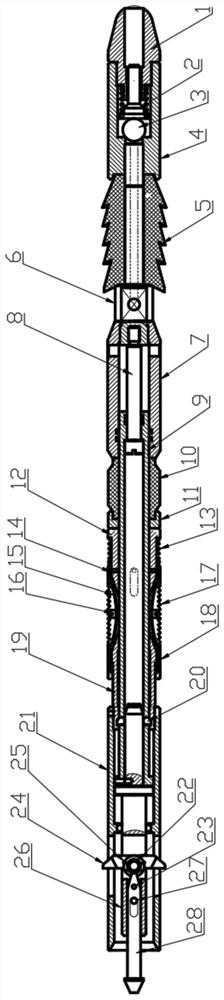

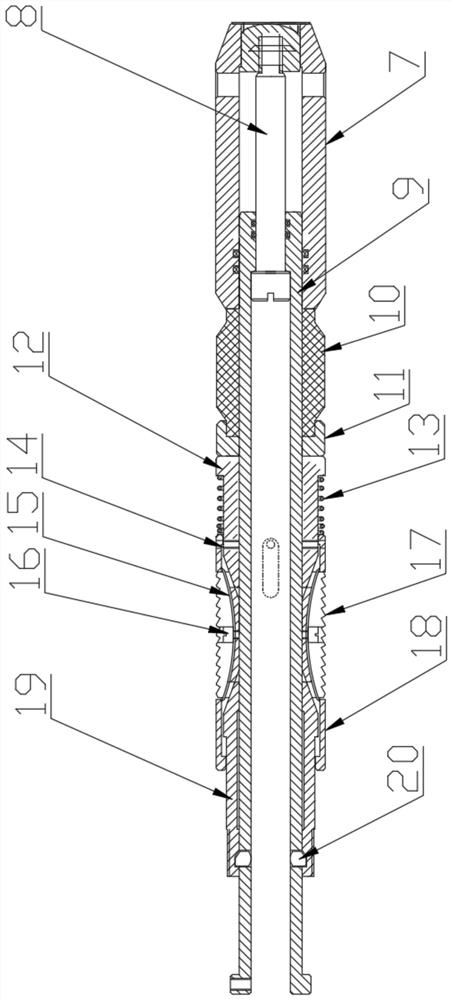

[0037] Such as figure 1 As shown in Fig. 1, a plugging device in a hydraulic feeding wire salvage oil pipe, including a guide mechanism, a seat seal mechanism, and a salvage mechanism,

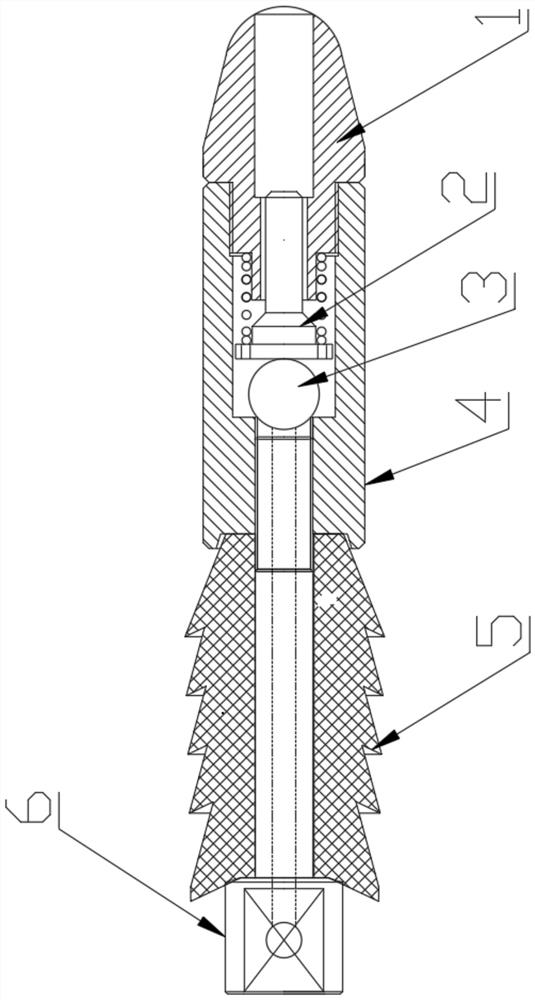

[0038] Such as figure 2 As shown, the guide mechanism includes a guide head 1, a valve core 2, a ball 3, a valve body 4, a rubber tower 5, and a rubber tower shaft 6; the guide head 1 is conical, and a through hole is provided in the center to guide The valve body 4 is detachably connected to the rear of the head 1; the valve body 4 is cylindrical, and the center runs through, and a cavity is formed between the valve body 4 and the guide head 1, and a ball 3 and a valve core 2 are installed in the cavity , the spool 2 is a rotary part with a T-shaped cross-section, the ball 3 withstands the through hole at the rear end of the valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com