Fertilizer mixing secondary filling equipment for farming and easy to clean

A filling equipment and fertilizer technology, which is applied to the field of fertilizer mixing and secondary filling equipment for farming, can solve the problems of inconvenient adjustment, inconvenient plant fertilization work, inconvenient cleaning work, etc., and achieve the effect of preventing fertilizer waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

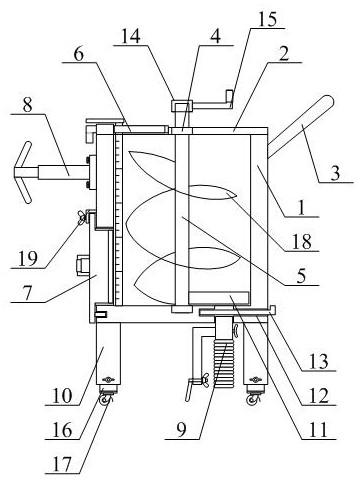

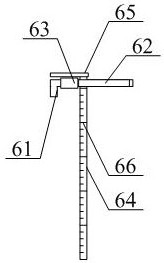

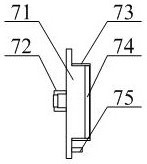

[0033]Below in conjunction with accompanying drawing, the present invention is described in detail, as shown in accompanying drawing 1 and accompanying drawing 2, the cultivation fertilizer that is convenient to clean up mixes secondary filling equipment, comprises mixing barrel 1, shielding cover 2, push rod 3, deep groove ball Bearing 4, mixing rotating rod 5, slidable support measuring cover structure 6, observable seal cleaning pipe structure 7, adjustable rotating draw bar structure 8, grooveable fertilization pipe structure 9, support pipe 10, push plate 11, plug-in Groove 12, L-shaped plug plate 13, connecting cover 14, L-shaped rotating rod 15, telescopic rod 16, moving wheel 17, spiral plate 18 and L-shaped locking plate 19, the shielding cover 2 is bolted to the mixing barrel 1 on the right side of the upper end; the push rod 3 bolts are connected to the upper right side of the mixing bucket 1; the deep groove ball bearings 4 are respectively embedded in the inner mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com