A kind of ultra-low temperature silent bearing lubricating grease and its preparation process

A silent bearing and lubricating grease technology, which is applied in the field of lubricating grease, can solve the problems of large viscosity changes of lubricating grease, many impurities, and large starting torque of bearings, etc., achieve low starting/running torque, improve thickener distribution, and excellent low temperature The effect of flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

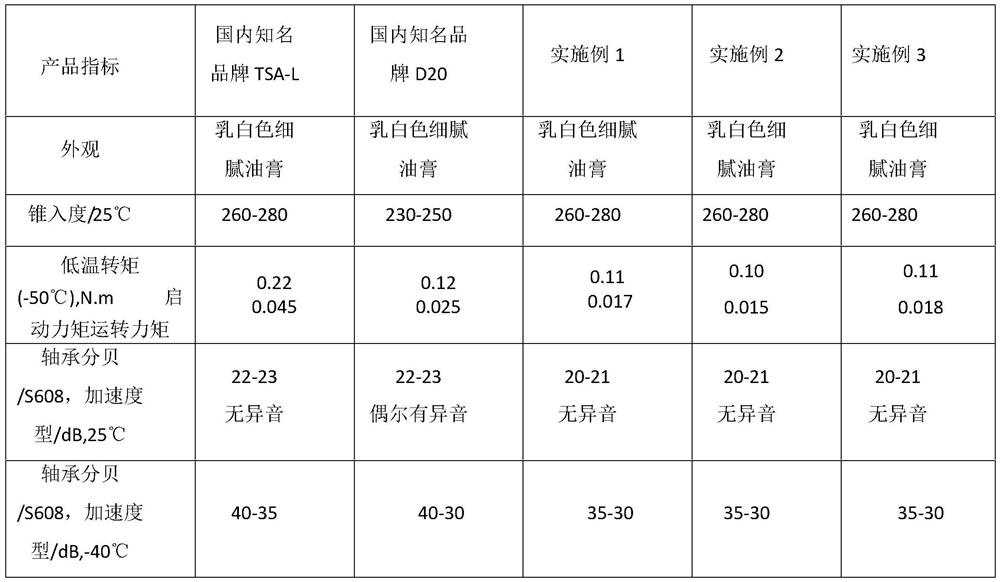

Examples

Embodiment 1

[0035] The preparation of raw materials involved in the following examples:

[0036] Take 420gPAO6 and 180gPAO4 and mix to form a mixed oil, which is placed in the production intermediate tank for standby;

[0037] Weigh 10 g of lithium hydroxide, add 80 g of water and mix it to prepare a lithium hydroxide solution;

[0038] Additives: 5g diphenylamine, 5g dihexadi-tert-butyl-p-cresol and 10g barium petroleum sulfonate;

[0039] Take 150g of PAO4 and PAO6 mixed oil, add 50g of nano-scale PTFE powder to it, and uniformly disperse by high-speed ultrasonic to form a nano-scale PTFE solution;

[0040] Take 350g of PAO4 and PAO6 mixed oil and add it to the reactor and heat up to 90°C, add 70g of dodecahydroxystearic acid to the reactor, stir and dissolve evenly, filter for 1h in a loop, filter precision 1μm, and the temperature of the reactor material is warmed up to At 95 °C, add 90 g of lithium hydroxide aqueous solution, continue to heat up to 205 °C after saponification for 3...

Embodiment 2

[0042] Raw material preparation: Mix 420gPAO6 and 180gPAO4 to form a mixed oil, which is placed in the production intermediate tank for use;

[0043] Weigh 10 g of lithium hydroxide, add 80 g of water and mix it to prepare a lithium hydroxide solution;

[0044] Additives: 10g diphenylamine and 10g barium petroleum sulfonate;

[0045] Take 100g of PAO4 and PAO6 mixed oil, add 50g of nano-scale PTFE powder to it, and uniformly disperse by high-speed ultrasonic to form a nano-scale PTFE solution;

[0046]Take 300g of PAO4 and PAO6 mixed oil and add it to the reaction kettle and heat up to 90°C, add 70g of dodecylhydroxystearic acid to the reaction kettle, stir and dissolve evenly, filter for 1.5h in a filter cycle, filter precision 2μm, and heat up the temperature of the material in the reaction kettle When it reaches 100 °C, add 90 g of lithium hydroxide aqueous solution, continue to heat up to 210 °C after saponification for 3 hours, add 100 g of synthetic ester, stir for 5 mi...

Embodiment 3

[0048] Raw material preparation: Mix 600gPAO6 and 400gPAO4 to form a mixed oil, which is placed in the production intermediate tank for use;

[0049] Weigh 12g of lithium hydroxide, add 80g of water and mix it to prepare a lithium hydroxide solution;

[0050] Additives: 10g diphenylamine, 10g dihexadi-tert-butyl-p-cresol and 10g barium petroleum sulfonate;

[0051] Take 150g of PAO4 and PAO6 mixed oil, add 100g of nano-scale PTFE powder to it, and uniformly disperse by high-speed ultrasonic to form a nano-scale PTFE solution;

[0052] Take 400g of PAO4 and PAO6 mixed oil and add it to the reaction kettle and heat up to 100°C, add 120g of dodecahydroxystearic acid to the reaction kettle, stir and dissolve evenly, filter for 1.5h in a circulating filter, filter accuracy 2μm, and heat up the temperature of the material in the reaction kettle When it reaches 102 °C, add 92 g of lithium hydroxide aqueous solution, continue to heat up to 218 °C after saponification for 3 hours, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com