Ultralow-temperature mute bearing grease and preparation process thereof

A silent bearing and preparation technology, applied in the field of lubricating grease, can solve problems such as large viscosity changes of lubricating grease, many impurities, damage to machine motors and other components, and achieve low starting/running torque, excellent low temperature fluidity, and long oxidation. The effect of the induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

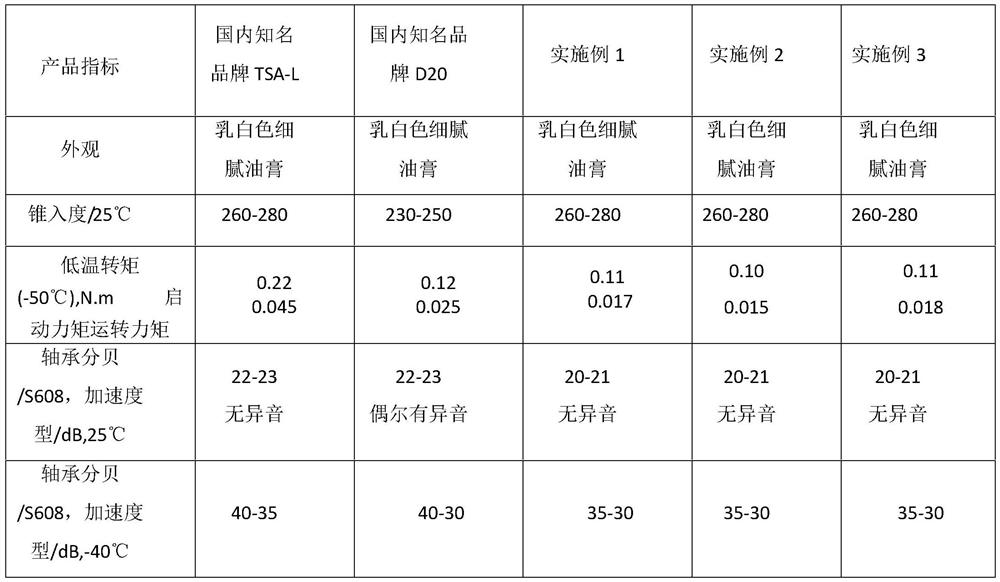

Examples

Embodiment 1

[0035] The raw material preparation that following embodiment relates to:

[0036] Get 420gPAO6 and 180gPAO4 and mix to form mixed oil, place the production intermediate tank for subsequent use;

[0037] Take lithium hydroxide 10g, mix after adding 80g water wherein, prepare lithium hydroxide solution;

[0038] Additives: 5g diphenylamine, 5g di-tert-butyl-p-cresol and 10g barium petroleum sulfonate;

[0039] Get 150g of PAO4 and PAO6 mixed oil, add 50g of nano-sized PTFE powder thereinto, and disperse evenly with high-speed ultrasonic to form a nano-sized PTFE solution;

[0040] Take 350g of PAO4 and PAO6 mixed oil into the reactor and heat up to 90°C, add 70g of lauryl hydroxystearic acid into the reactor, stir and dissolve evenly, and circulate the filter for 1h with a filter precision of 1μm, and the temperature of the reactor material is raised to At 95°C, add 90g of lithium hydroxide aqueous solution, continue to heat up to 205°C after saponification for 3 hours, add 1...

Embodiment 2

[0042] Raw material preparation: take 420gPAO6 and 180gPAO4 and mix to form a mixed oil, which is placed in the production intermediate tank for standby;

[0043] Take lithium hydroxide 10g, mix after adding 80g water wherein, prepare lithium hydroxide solution;

[0044] Additives: 10g diphenylamine and 10g barium petroleum sulfonate;

[0045] Get 100g of PAO4 and PAO6 mixed oil, add 50g of nano-sized PTFE powder to it, and disperse evenly with high-speed ultrasonic to form a nano-sized PTFE solution;

[0046]Take 300g of PAO4 and PAO6 mixed oil and add it to the reactor to raise the temperature to 90°C, add 70g of lauryl hydroxystearic acid to the reactor, stir and dissolve evenly, and circulate the filter for 1.5h, the filter precision is 2μm, and the temperature of the reactor material is raised When it reaches 100°C, add 90g of lithium hydroxide aqueous solution, continue to heat up to 210°C after saponification for 3 hours, add 100g of synthetic ester, stir for 5 minutes...

Embodiment 3

[0048] Raw material preparation: take 600gPAO6 and 400gPAO4 and mix to form a mixed oil, which is placed in the production intermediate tank for standby;

[0049] Take lithium hydroxide 12g, mix homogeneously after adding 80g water wherein, be prepared into lithium hydroxide solution;

[0050] Additives: 10g diphenylamine, 10g di-t-butyl-p-cresol and 10g barium petroleum sulfonate;

[0051] Get 150g of PAO4 and PAO6 mixed oil, add 100g of nano-sized PTFE powder to it, and disperse evenly with high-speed ultrasonic to form a nano-sized PTFE solution;

[0052] Take 400g of PAO4 and PAO6 mixed oil and add it to the reactor to raise the temperature to 100°C. Add 120g of dodecyl hydroxystearic acid to the reactor, stir and dissolve evenly, and circulate the filter for 1.5h with a filter precision of 2μm. When the temperature reaches 102°C, add 92g of lithium hydroxide aqueous solution, continue to heat up to 218°C after saponification for 3 hours, add 150g of synthetic ester, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com