Multifunctional diaphragm and biological microporous plate microimaging light path device

A microscopic imaging and multi-functional technology, applied in the optical field, can solve problems such as unfavorable accuracy, and achieve the effect of compact structure, improved optical path, and uniform light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

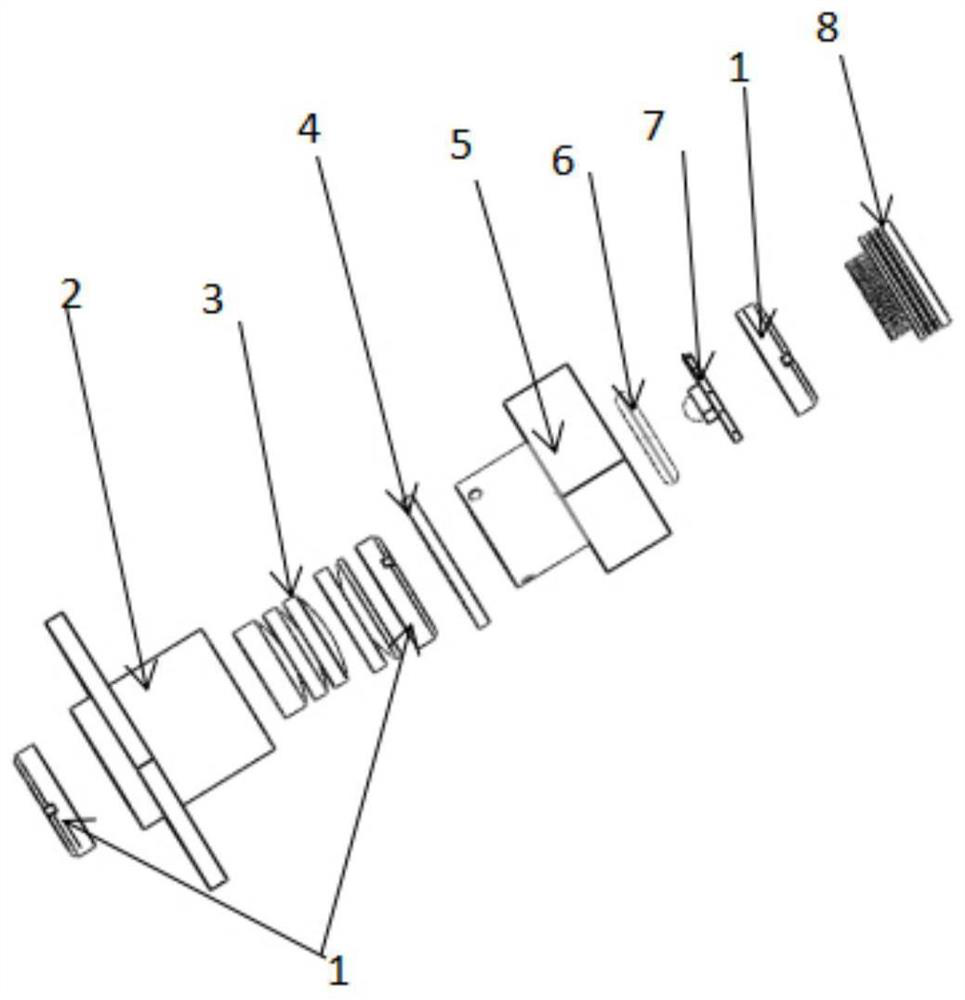

[0053] This embodiment provides an optical path device for microscopic imaging of a biological microplate, and the structural schematic diagram of the optical path device for microscopic imaging of a biological microplate is as follows figure 1 As shown, it includes three sequentially arranged light source components, diaphragm components and imaging lens groups; the central axis of the light source component, the central axis of the three imaging lens groups and the central axis of the multifunctional diaphragm 4 coincide.

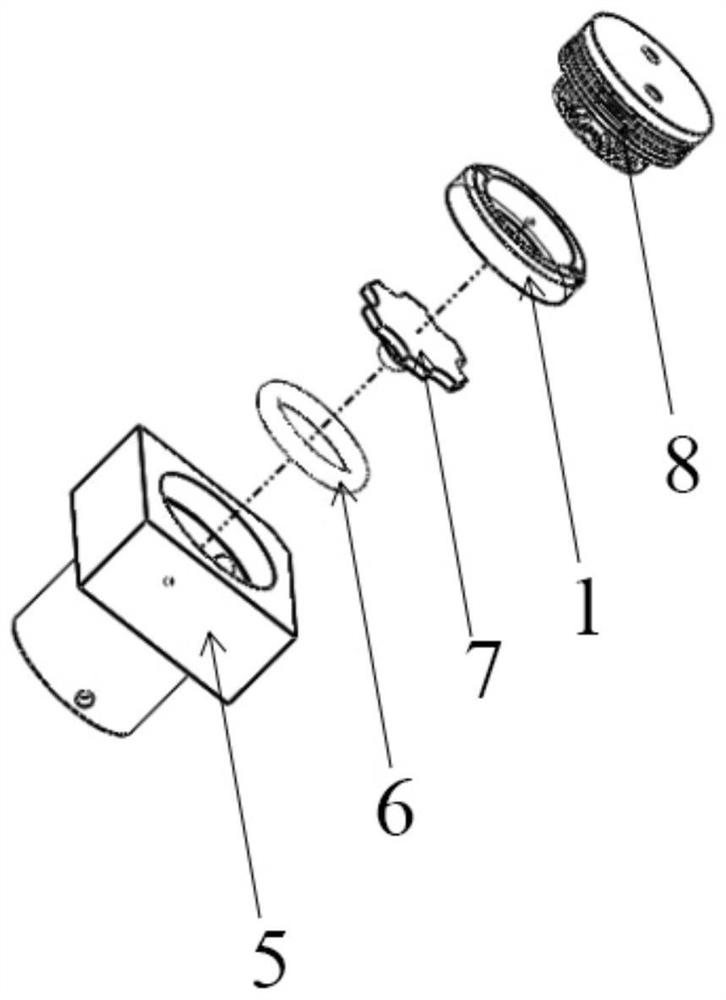

[0054] The structural schematic diagram of the light source assembly is as follows figure 2 As shown, it includes a light source seat 5, a sealing ring 6, an LED light source 7, a fixing part 1 and a heat sink 8, and the central axes of the light source seat 5, the sealing ring 6, the LED light source 7, the fixing part 1 and the heat sink 8 coincide; The sealing ring 6 and the fixing member 1 are used to fix the LED light source 7 to the light source se...

Embodiment 2

[0060] This embodiment provides an optical path device for microscopic imaging of a biological microplate, and the structural schematic diagram of the optical path device for microscopic imaging of a biological microplate is as follows figure 1 As shown, it includes three sequentially arranged light source components, diaphragm components and imaging lens groups; the central axis of the light source component, the central axis of the three imaging lens groups and the central axis of the multifunctional diaphragm 4 coincide.

[0061] The structural schematic diagram of the light source assembly is as follows figure 2 As shown, it includes a light source seat 5, a sealing ring 6, an LED light source 7, a fixing part 1 and a heat sink 8, and the central axes of the light source seat 5, the sealing ring 6, the LED light source 7, the fixing part 1 and the heat sink 8 coincide; The sealing ring 6 and the fixing member 1 are used to fix the LED light source 7 to the light source se...

Embodiment 3

[0068] This embodiment provides an optical path device for microscopic imaging of a biological microplate, and the structural schematic diagram of the optical path device for microscopic imaging of a biological microplate is as follows figure 1 As shown, it includes three sequentially arranged light source components, diaphragm components and imaging lens groups; the central axis of the light source component, the central axis of the three imaging lens groups and the central axis of the multifunctional diaphragm 4 coincide.

[0069] The structural schematic diagram of the light source assembly is as follows figure 2 As shown, it includes a light source seat 5, a sealing ring 6, an LED light source 7, a fixing part 1 and a heat sink 8, and the central axes of the light source seat 5, the sealing ring 6, the LED light source 7, the fixing part 1 and the heat sink 8 coincide; The sealing ring 6 and the fixing member 1 are used to fix the LED light source 7 to the light source se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap