Steel strand bending device and using method thereof

A technology of steel strands and benders, applied in the field of power tools, can solve problems such as time-consuming and laborious, and achieve the effects of improving process quality, strong applicability, and simple and fast bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

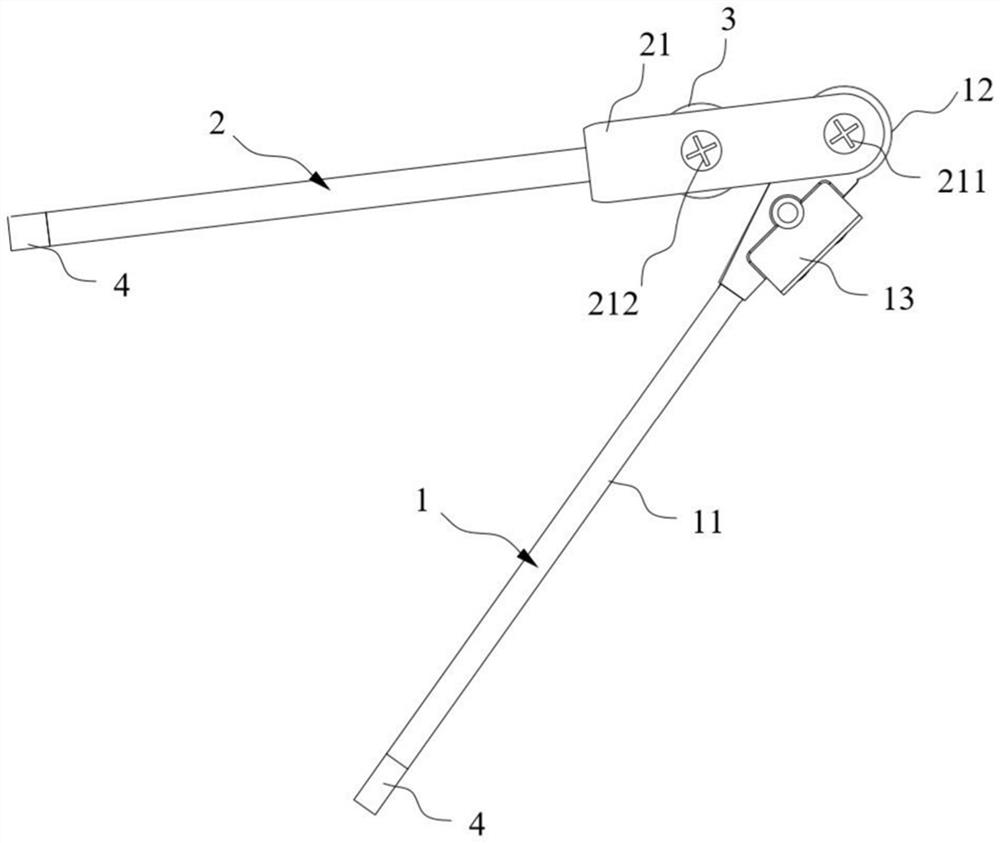

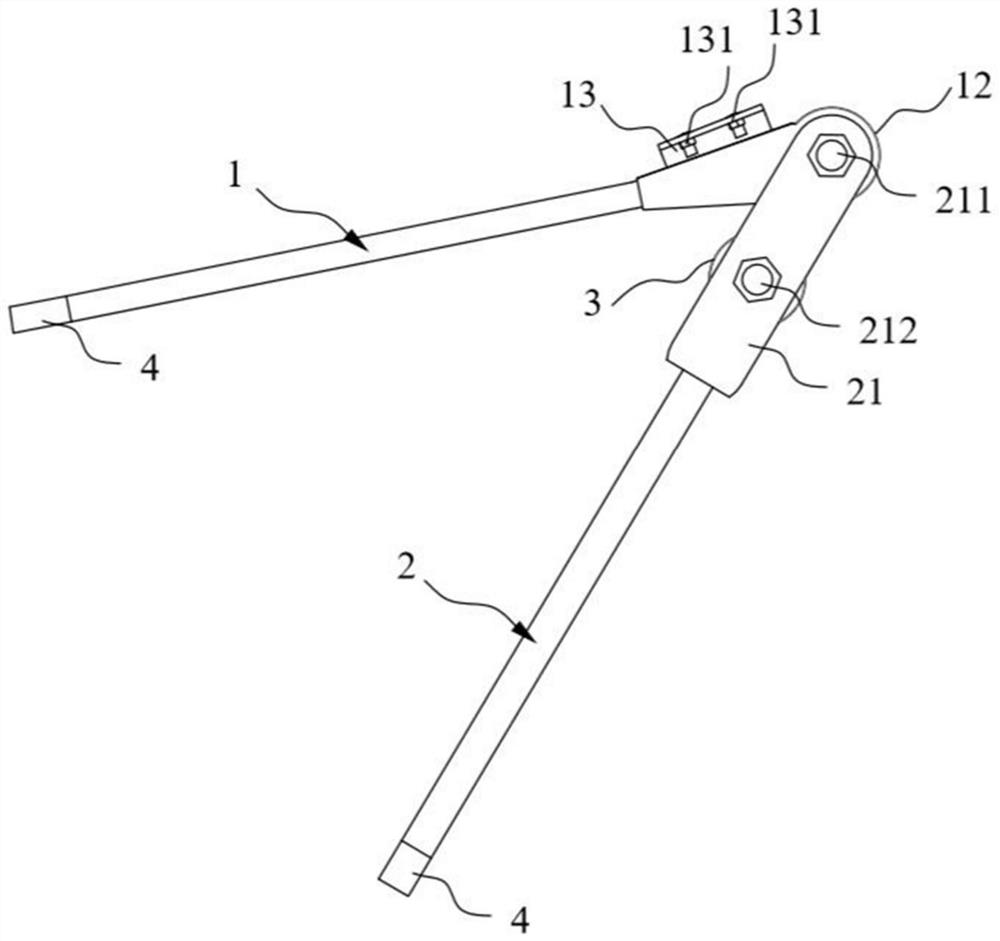

[0035] This embodiment provides a steel strand bender, such as figure 1 and figure 2 As shown, it includes a rod body 11 , an arc-shaped end 12 and a rotating handle 2 . There are multiple arc-shaped ends 12, and the radii of the outer edges of the plurality of arc-shaped ends 12 increase sequentially. One end of the rod body 11 can be selectively connected to an arc-shaped end 12 to form a fixed handle 1. One side of the arc-shaped end 12 is provided with Fixed part 13, fixed part 13 is used for fixing one end of the steel strand; One end of the rotating handle 2 is the working end, and the working end is connected with the arc-shaped end 12 of the fixed handle 1 in rotation. One end of the stranded wire is fixed by the fixing part 13, and when the other end goes around the arc-shaped end 12 and passes through the wire passing hole, the rotating handle 2 can rotate toward the fixed handle 1 to bend the steel stranded wire. Among them, the steel strand bender has a pluralit...

Embodiment 2

[0047] This embodiment provides a method for using the steel strand bender provided in the first embodiment, wherein the same or corresponding components as those in the first embodiment are designated with reference numerals corresponding to those in the first embodiment. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that the method for using the steel strand bender provided in Embodiment 1 includes the following steps:

[0048] S1. According to the working conditions, select the arc-shaped end 12 with the required outer edge radius and connect it with the rod body 11, and then connect it with the rotating handle 2;

[0049] S2. Rotate the rotating handle 2 and the fixed handle 1 to form a preset angle;

[0050] S3. Fix one end of the steel strand to the fixed handle 1 through the fixing part 13, and the other end passes through the arc-shaped end 12 and passes through the wire through hole;

[0051] S4. The free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com