A kind of electronic component foot grinding and cleaning equipment

A technology for electronic components and cleaning equipment, which is applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc. It can solve problems such as incomplete grinding, easy shaking, and damage to PC boards, and achieve a clean grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

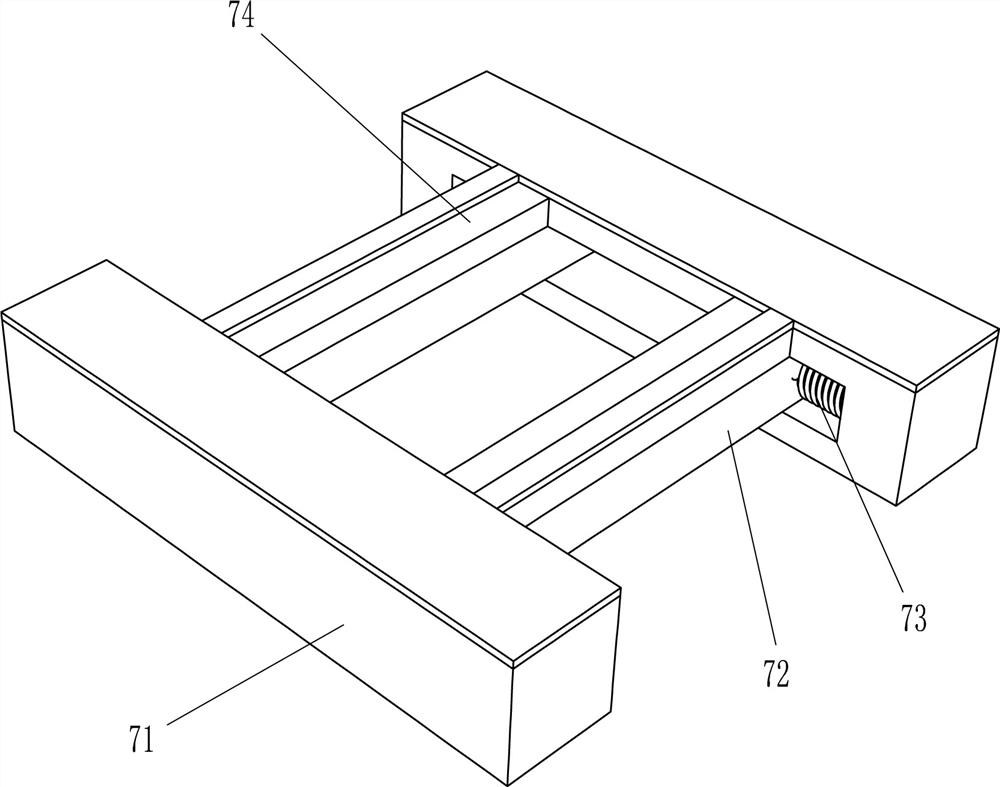

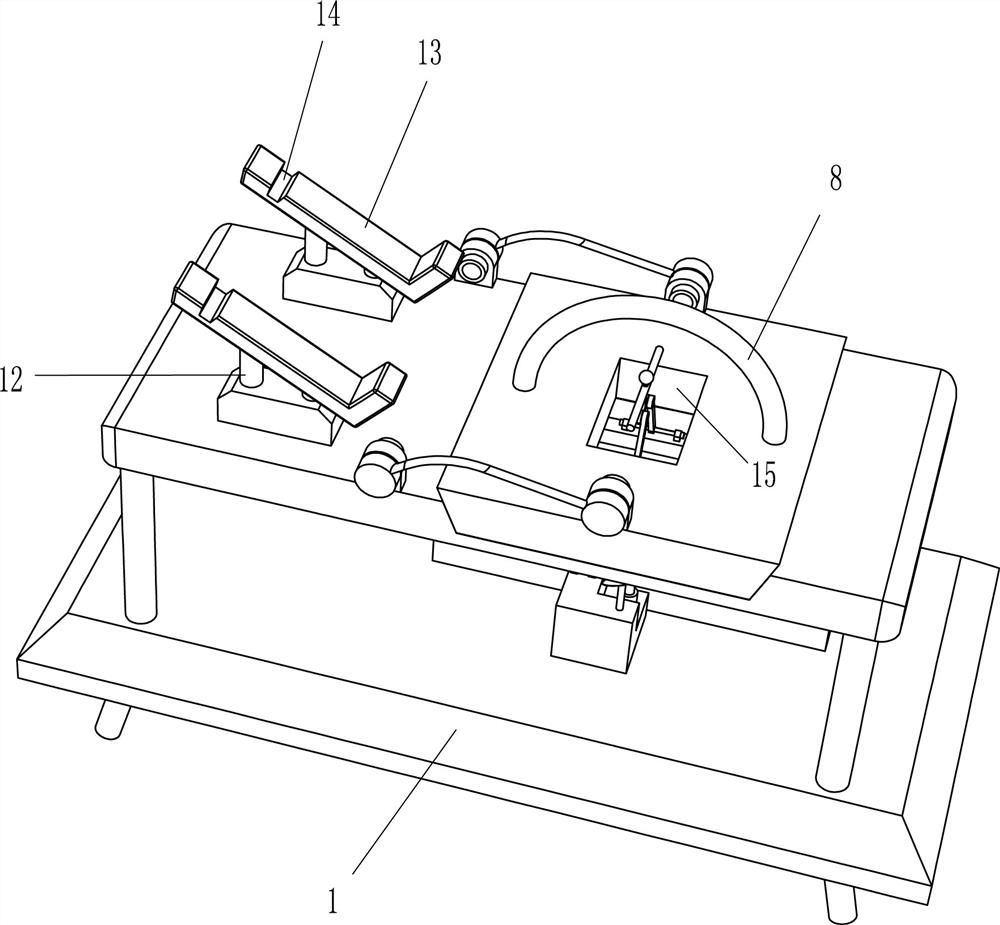

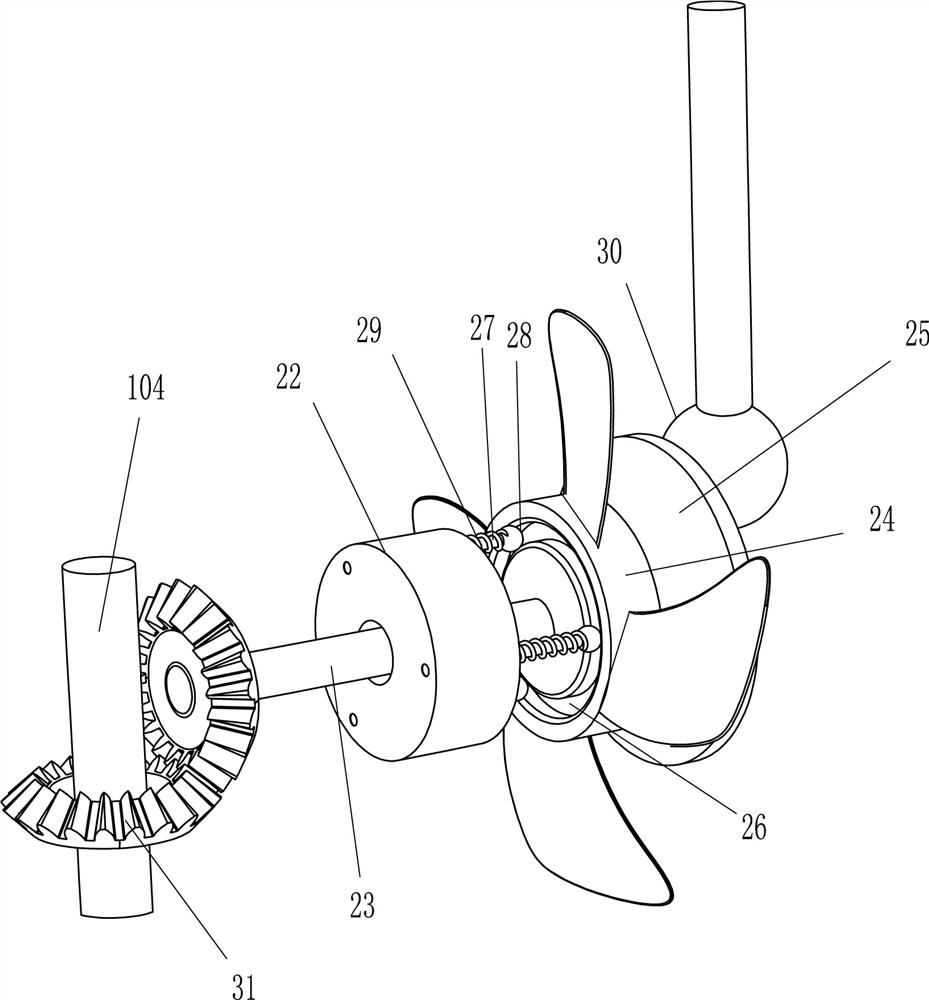

[0024] Such as figure 1 , 2 , 3 and shown, a grinding and cleaning equipment for electronic components feet, including a base 1, a workbench 2, a mounting seat 3, a rotating shaft 4, a connecting frame 5, a turning plate 6, a clamping mechanism 7, a handle 8, a grinding The mechanism 10 and the collection box 11, the top of the base 1 is provided with a workbench 2, the middle part of the trapezoidal chute on the workbench 2 is provided with a square hole 9, and the left side of the workbench 2 is symmetrically arranged with a mounting seat 3, two mounting seats 3 A rotating shaft 4 is provided, and a connecting frame 5 is arranged in a rotating manner on the two rotating shafts 4, and an overturning plate 6 is arranged between the left ends of the two connecting frames 5, and the overturning plate 6 is matched with the trapezoidal chute on the workbench 2, and the overturning plate 6 The middle part of the side that cooperates with the trapezoidal chute on the workbench 2 is...

Embodiment 2

[0029] On the basis of Example 1, such as figure 2 , 4, 5 and 6, also include support 12, L-shaped placement frame 13, rotating rod 151, connecting rod 16, connecting block 17, moving rod 18, top ball 19, fixed rod 20 and second elastic member 21, work The left side of the top of the table 2 is symmetrically arranged with brackets 12 by means of welding, and the tops of the two brackets 12 are provided with L-shaped placement racks 13, and the L-shaped placement racks 13 are inclined towards the direction of the square hole 9. Draw-in slot 14, square hole 15 is arranged in the middle part of turnover plate 6, and slide block 72 is provided with rotating rod 151 symmetrically near the side of square hole 15, and the middle part of two rotating rods 151 is connected with connecting rod 16 in a rotating manner, between the other ends of the two connecting rods 16. The connecting block 17 is provided with a rotating type, the middle part of the connecting block 17 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com