Furniture maintenance device

A furniture and intermediate position technology, which is applied to grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc. The effect of maintenance in place, smooth polishing, and brightness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

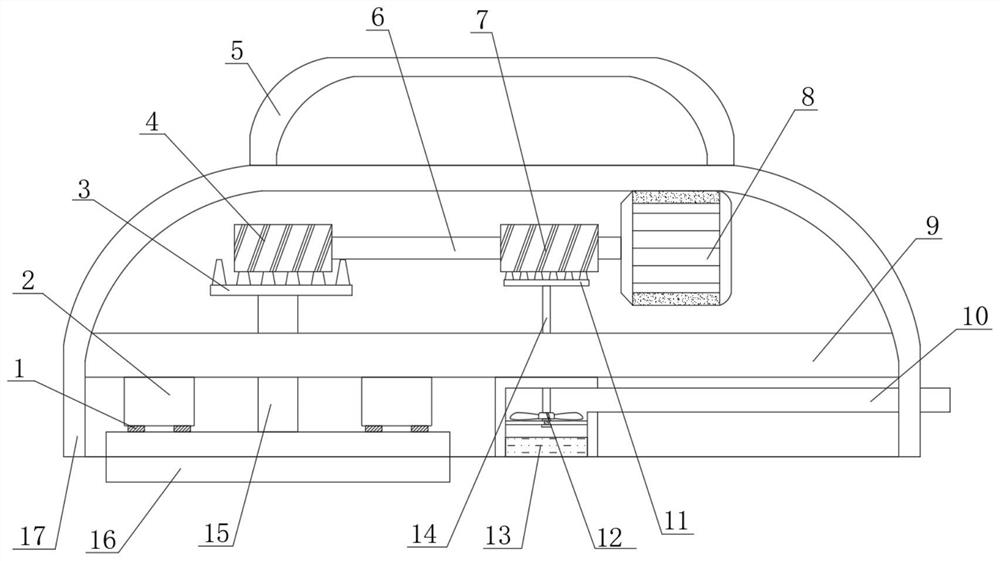

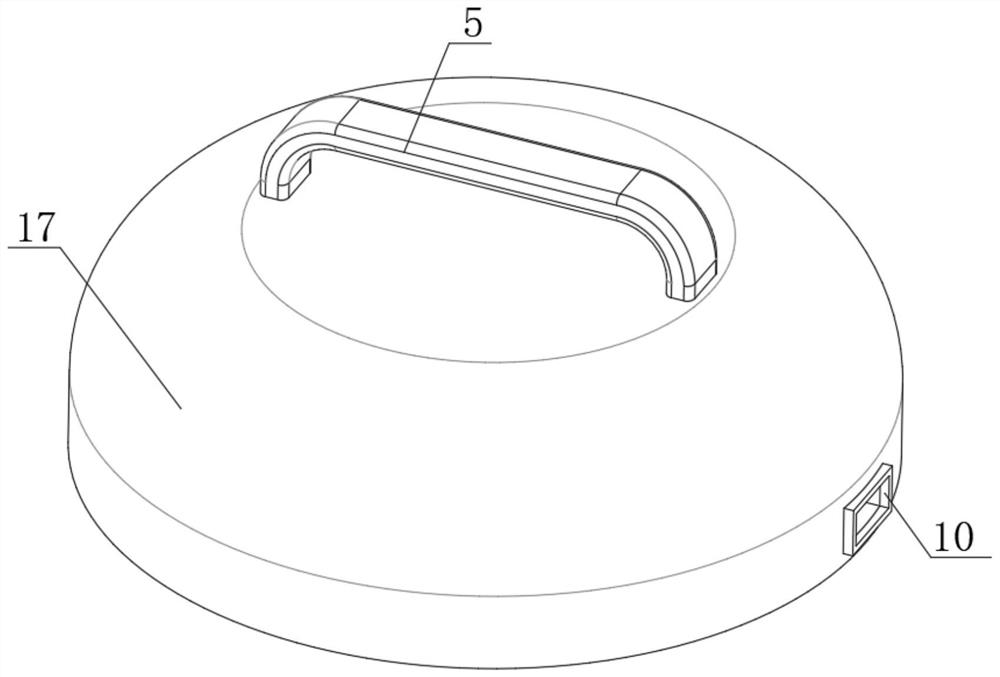

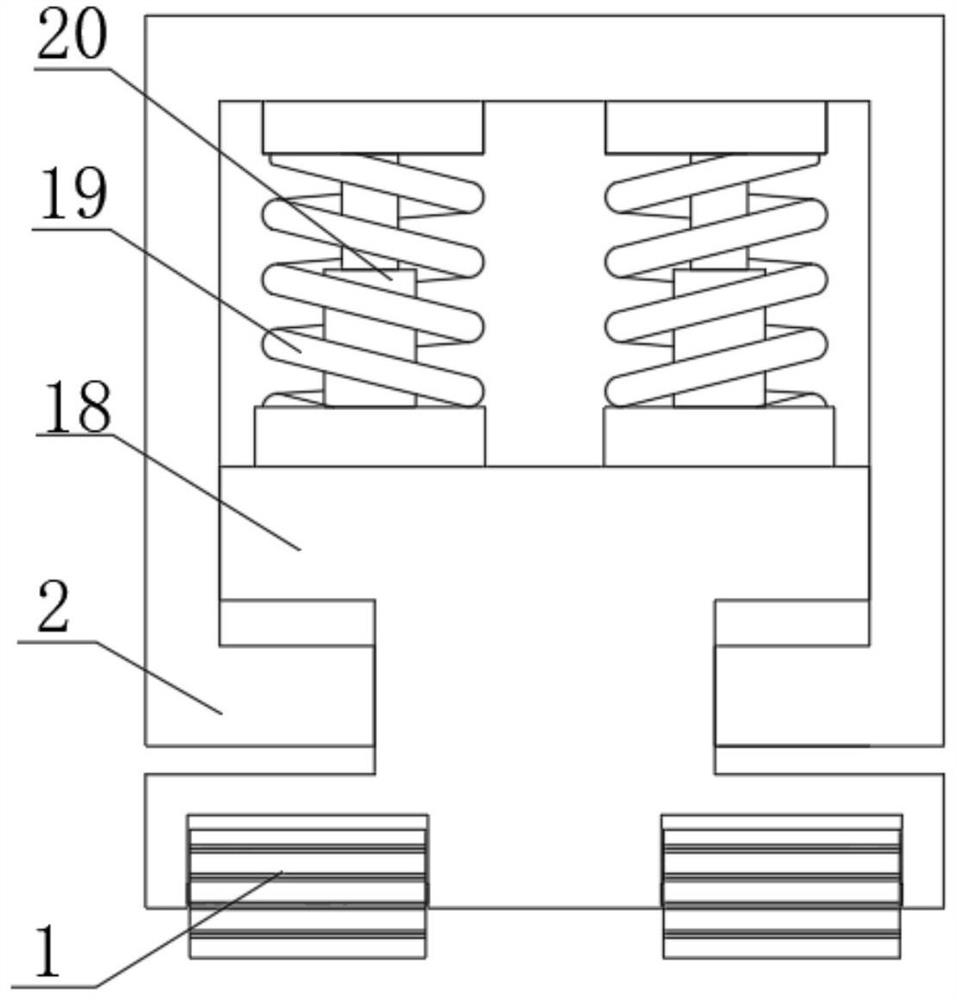

[0028]A furniture maintenance device, such asFigure 1-3 As shown, the main frame 17 is included. The central position of the inner circumferential wall of the main frame 17 is fixed with a horizontal fixed middle plate 9 through bolts, and one end of the top inner wall of the main frame 17 is fixed with a horizontally arranged electric motor 8 through bolts. The shaft is fixed with a horizontal rotating central shaft 6, one end of the circumferential outer wall of the rotating central shaft 6 is sleeved with a horizontally arranged driving screw 4, and one end between the top and bottom of the fixed middle plate 9 is provided with a first hole, and The inner circumferential wall of the first hole is sleeved with a driving rod 15, and a horizontal bevel gear 3 is fixed on the top of the driving rod 15. The top of the bevel gear 3 meshes with the circumferential outer wall of the driving screw 4 to drive the rotation The bottom position of the rod 15 is fixed with a horizontal grindin...

Embodiment 2

[0032]A furniture maintenance device, such asFigure 1-4As shown, the other end of the output shaft of the motor 8 is fixed with a vertically arranged drive gear 21, and the other end of the top and bottom of the fixed middle plate 9 is provided with a third hole, and the third hole is sleeved with a vertically arranged driving gear. Rod three 24, the top of the driving rod three 24 is fixed with a horizontally arranged rotating gear 22, and the rotating gear 22 meshes with the driving gear 21, the bottom of the driving rod three 24 is fixed with a horizontally arranged polishing disc 25, and ash is discharged The bottom end of the pipe 10 is fixed with a horizontally arranged liquid outlet plate 26, and the top of one end of the main box 17 is fixed with a vertically arranged liquid inlet pipe 23, and the bottom of the liquid inlet pipe 23 is sleeved with the liquid outlet plate 26.

[0033]When this embodiment is in use, a horizontal polishing disk 25 is installed at the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com