An olive anti-attenuation high-strength pp spunbonded nonwoven fabric

A technology of spunbonded non-woven fabrics and olive resistance, which is applied in the direction of non-woven fabrics, textiles and papermaking, fiber chemical characteristics, etc., can solve the problems of weak filtration rate, weak oxidation resistance and static electricity of the outer spunbonded non-woven fabrics. Adsorption capacity decline and other problems, to achieve the effect of prolonging the electrostatic adsorption time, good antibacterial performance, sphericity and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

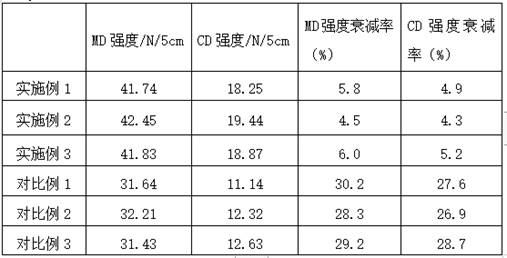

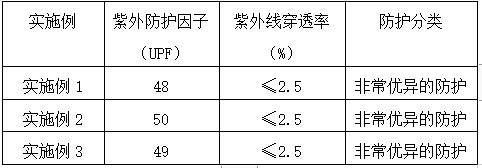

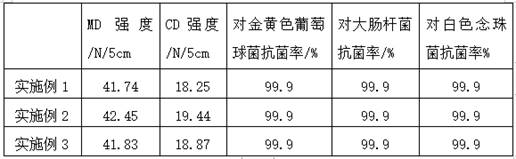

Examples

Embodiment 1

[0050] Embodiment 1 A kind of preparation method of olive anti-attenuation high-strength PP spunbonded nonwoven fabric, comprising:

[0051] The polypropylene high polymer is melted and extruded through a large screw extruder, filtered, spun, air-drawn and stretched to lay the filaments into a web, and the fiber web is passed through the upper and lower pressure rollers, and the rolling mill is hot-rolled and bonded to form a spun-bonded non-woven fabric. Spinning, and finally winding, cutting, prepared into PP spunbond non-woven fabric;

[0052] Specifically include the following steps:

[0053] 1. Add polypropylene and polypropylene masterbatch to the large screw extruder according to the mass ratio, and the amount of the modified polypropylene masterbatch accounts for 1% of the total mass of the spunbond nonwoven fabric in terms of olive leaf extract ;First heat to 90°C in the first zone mixing stage, mix at medium speed for 25 minutes, then add modified polypropylene mast...

Embodiment 2

[0077] Embodiment 2 A kind of preparation method of olive anti-attenuation high-strength PP spunbonded nonwoven fabric, comprising:

[0078] The polypropylene high polymer is melted and extruded through a large screw extruder, filtered, spun, air-drawn and stretched to lay the filaments into a web, and the fiber web is passed through the upper and lower pressure rollers, and the rolling mill is hot-rolled and bonded to form a spun-bonded non-woven fabric. Spinning, and finally winding, cutting, prepared into PP spunbond non-woven fabric;

[0079] Specifically include the following steps:

[0080] 1. Add polypropylene and modified polypropylene masterbatch to the large screw extruder according to the mass ratio, and the amount of the modified polypropylene masterbatch accounts for 10% of the total mass of the spunbonded nonwoven fabric in terms of olive leaf extract 2%; first heat to 80°C in the mixing stage of zone 1, mix at medium speed for 20 minutes, then add modified poly...

Embodiment 3

[0104] Embodiment 3 A kind of preparation method of olive anti-attenuation high-strength PP spunbonded nonwoven fabric, comprising:

[0105] The polypropylene high polymer is melted and extruded through a large screw extruder, filtered, spun, air-drawn and stretched to lay the filaments into a web, and the fiber web is passed through the upper and lower pressure rollers, and the rolling mill is hot-rolled and bonded to form a spun-bonded non-woven fabric. Spinning, and finally winding, cutting, prepared into PP spunbond non-woven fabric;

[0106] Specifically include the following steps:

[0107] 1. Add polypropylene and modified polypropylene masterbatch to the large screw extruder according to the mass ratio, and the amount of the modified polypropylene masterbatch accounts for 10% of the total mass of the spunbonded nonwoven fabric in terms of olive leaf extract 3%; first heat to 120°C in the mixing stage of zone 1, mix at medium speed for 40 minutes, then add modified pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com