A kind of electrostatic protection film and preparation method thereof

A protective film and electrostatic technology, applied in chemical instruments and methods, electronic equipment, and other household appliances, can solve the problems of residual glue and other problems, and achieve the effects of simple operation, low production cost, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

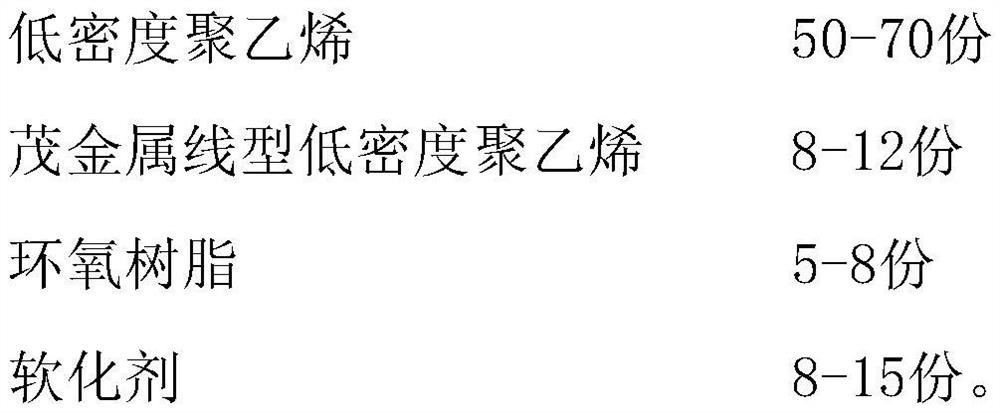

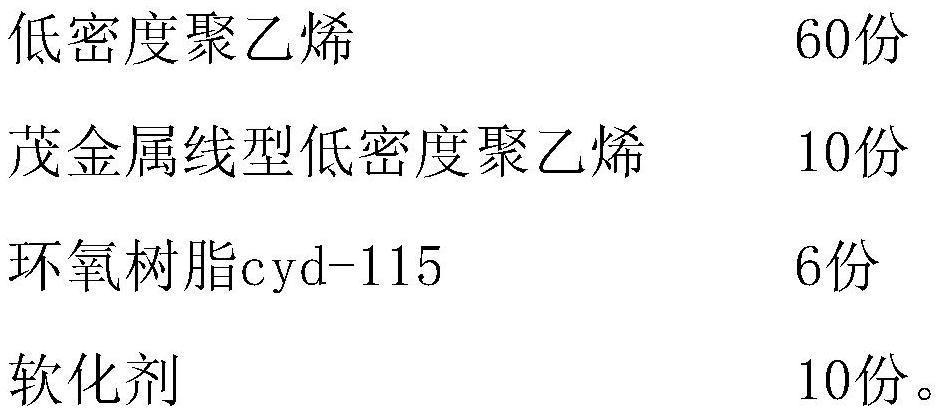

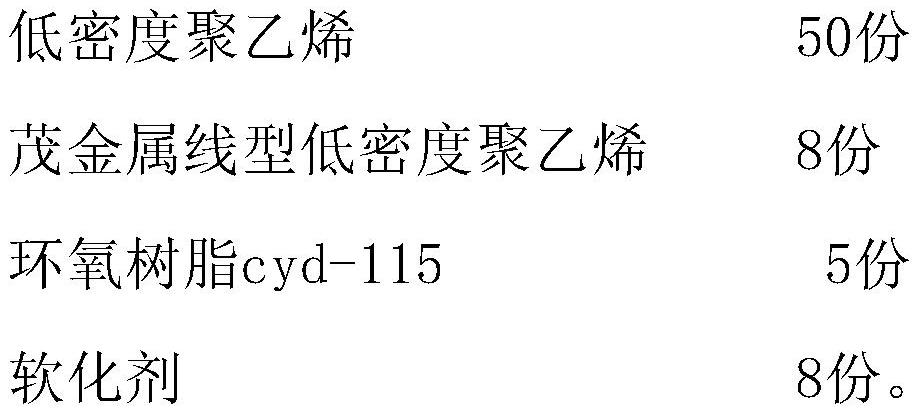

[0040] An electrostatic protective film, comprising an electrostatic adsorption layer and a protective layer co-extruded with the electrostatic adsorption layer; the electrostatic adsorption layer includes the following raw materials in parts by weight:

[0041] 60 parts of low-density polyethylene

[0042] Hydroxyl-terminated polydimethylsiloxane 12 parts

[0043] Vinyl silicone oil 3 parts.

[0044] The vinyl silicone oil is vinyl-terminated polydimethylsiloxane, and the vinyl content of the vinyl silicone oil is 0.65 mol%.

[0045] The preparation method of the hydroxyl-terminated polydimethylsiloxane comprises the following steps:

[0046] (R1), get 120 parts of cyclic siloxanes, 0.5 parts of alkaline solution, 12 parts of white carbon black, 0.8 parts of dispersant and 3 parts of water by weight, for subsequent use;

[0047] (R2), adding an alkaline solution to the cyclic siloxane, then stirring under the protection of a nitrogen environment and raising the temperature...

Embodiment 2

[0064] An electrostatic protective film, comprising an electrostatic adsorption layer and a protective layer co-extruded with the electrostatic adsorption layer; the electrostatic adsorption layer includes the following raw materials in parts by weight:

[0065] Low-density polyethylene 50 parts

[0066] Hydroxy-terminated polydimethylsiloxane 8 parts

[0067] Vinyl silicone oil 2 parts.

[0068] The vinyl silicone oil is vinyl-terminated polymethylvinyl siloxane, and the vinyl content of the vinyl silicone oil is 0.45 mol%.

[0069] The preparation method of the hydroxyl-terminated polydimethylsiloxane comprises the following steps:

[0070] (R1), take 100 parts of cyclic siloxane, 0.1 part of alkaline solution, 10 parts of white carbon black, 0.5 part of dispersant and 1 part of water by weight, and set aside;

[0071] (R2), adding an alkaline solution to the cyclic siloxane, then stirring under the protection of a nitrogen environment and raising the temperature to 140°C...

Embodiment 3

[0088] An electrostatic protective film, comprising an electrostatic adsorption layer and a protective layer co-extruded with the electrostatic adsorption layer; the electrostatic adsorption layer includes the following raw materials in parts by weight:

[0089] Low-density polyethylene 70 parts

[0090] Hydroxyl-terminated polydimethylsiloxane 15 parts

[0091] Vinyl silicone oil 4 parts.

[0092] The vinyl silicone oil is a mixture of vinyl-terminated polydimethylsiloxane and vinyl-terminated polymethylvinylsiloxane in a weight ratio of 1:1, and the vinyl content of the vinyl silicone oil is 0.80mol %.

[0093] The preparation method of the hydroxyl-terminated polydimethylsiloxane comprises the following steps:

[0094] (R1), get 150 parts of cyclic siloxanes, 1 part of alkaline solution, 15 parts of white carbon black, 1 part of dispersant and 5 parts of water by weight, for subsequent use;

[0095] (R2), adding an alkaline solution to the cyclic siloxane, then stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com