Sectional Beam Field Structure with Retaining Wall and Its Construction Method

A construction method and zoning technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problem of line layout and drainage system layout and traffic guidance restrictions, the inability to achieve complementary sharing of adjacent grading areas, and reduce costs. The area utilization rate of the beam-making and storage area has been improved, so as to improve the land utilization rate, enhance the beam-making and storage capacity, and facilitate the layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

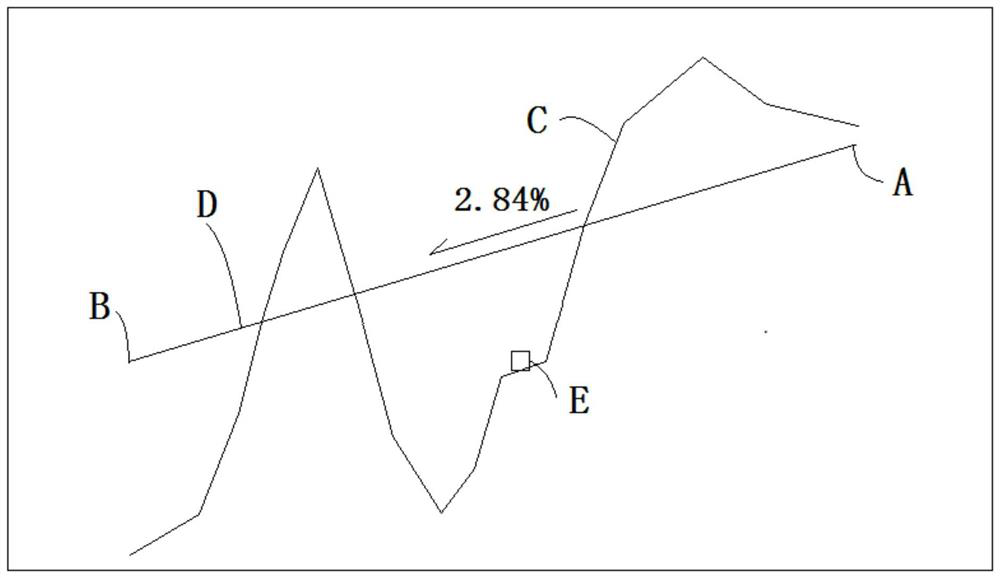

[0038] Water source protection areas in mountainous areas have high requirements for environmental protection and lack of large flat sites. The cost of land acquisition outside the red line is high, the cost of later reclamation is high, and the construction of access roads for transporting beams is difficult and expensive. plan is not feasible. In addition, the work area is located in the intercommunication circle of mountainous areas, the site is narrow and the line is in a curved section, so there are no conditions for the offline construction of beam yards for beam making, beam storage and beam lifting.

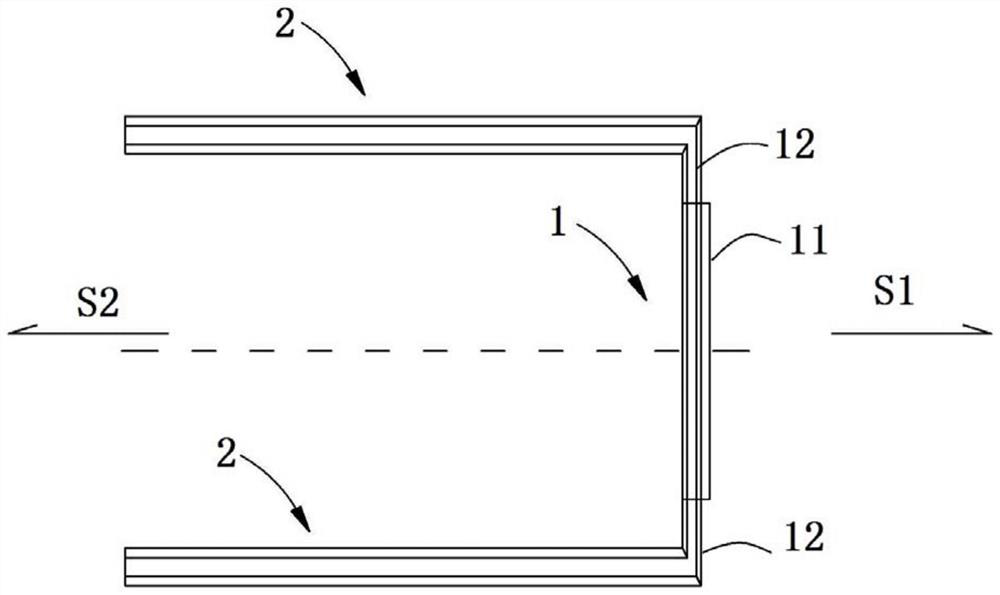

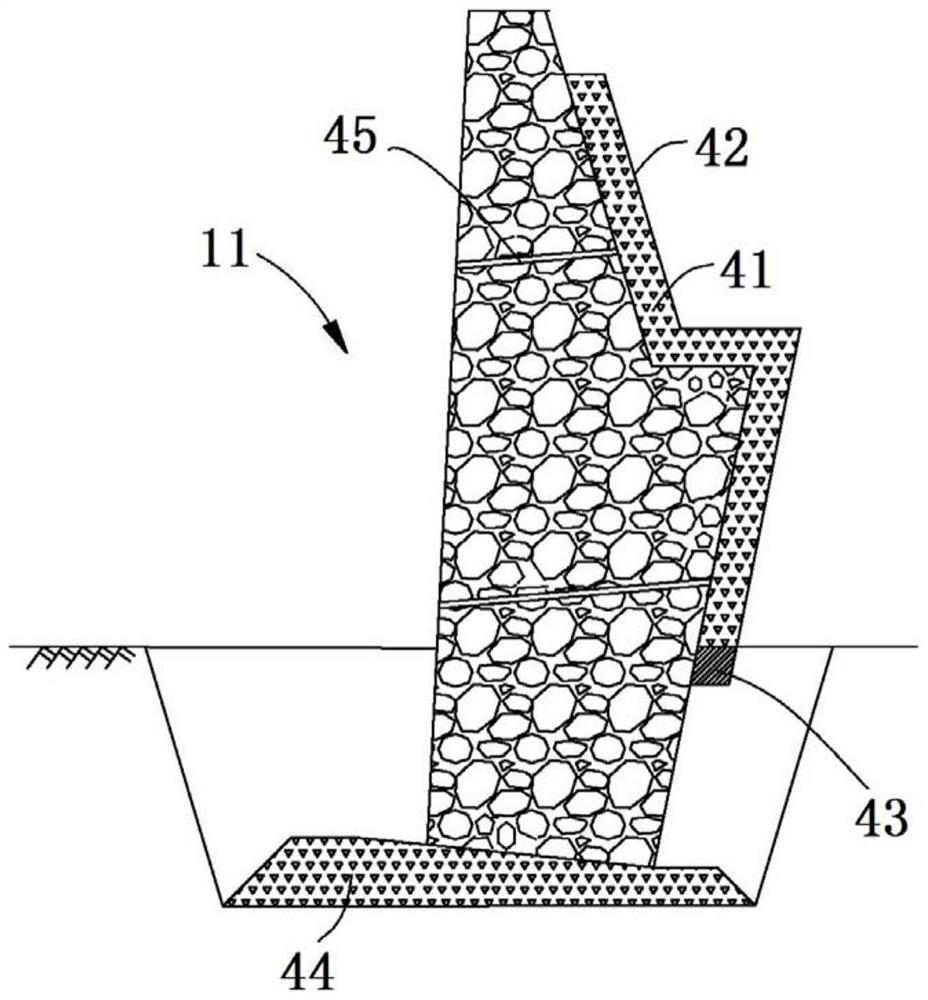

[0039] In order to solve the above-mentioned technical problems, the present invention provides a partitioned beam field structure with retaining walls, which includes a beam storage area S1 and a beam l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com