Centrifugal compressor working capacity one-dimensional algorithm based on impeller inlet natural prewhirl

A centrifugal compressor and impeller import technology, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problem that centrifugal compressors cannot achieve the power output, reduce the workload of model-level test correction, The effect of reducing calculation errors and avoiding insufficient power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

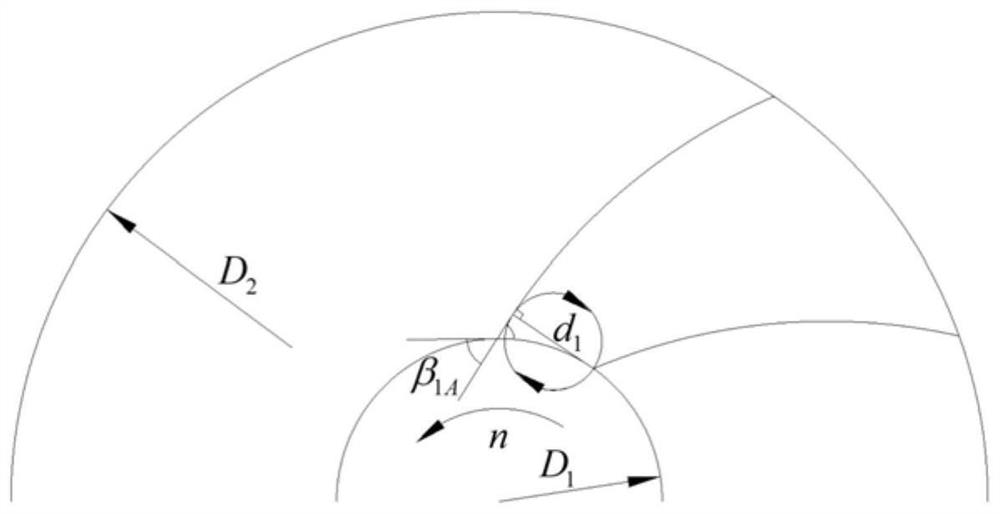

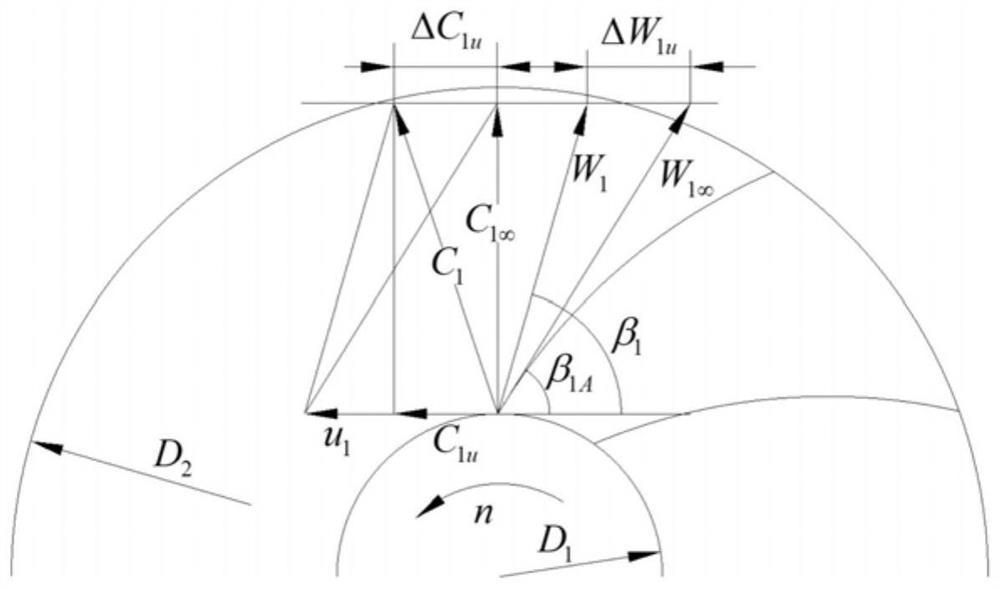

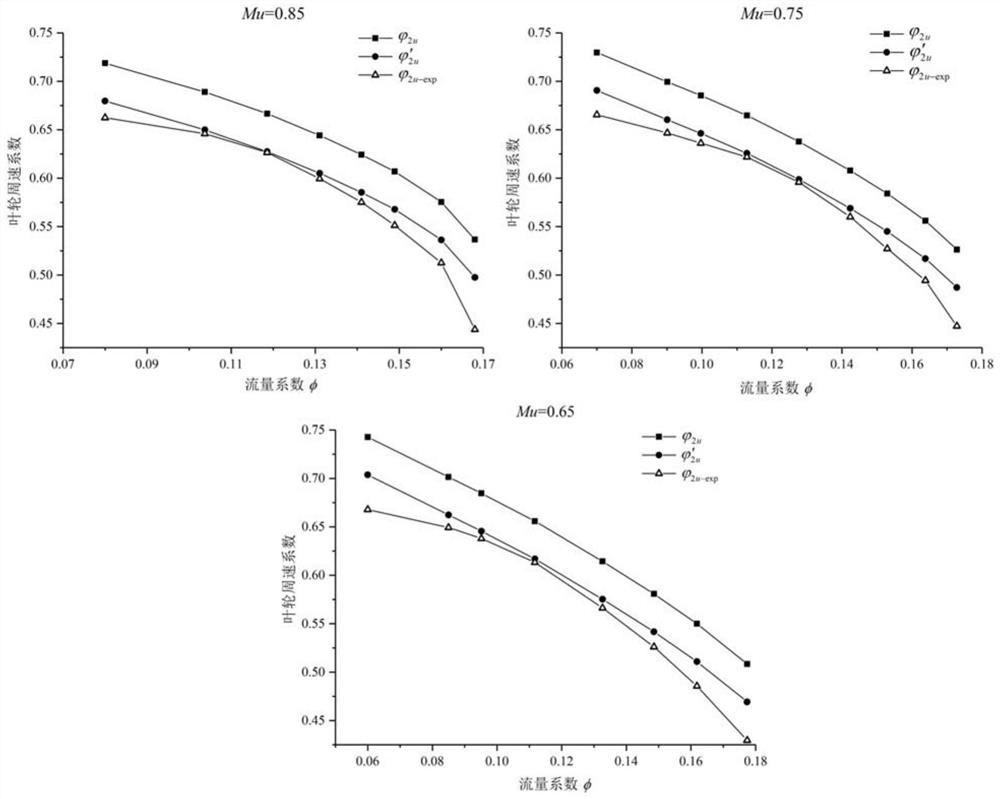

[0051] Such as figure 1 with figure 2 As shown, the present invention provides a one-dimensional algorithm for the performance of a centrifugal compressor based on the natural pre-rotation of the impeller inlet, including: 1) Considering the influence of the natural pre-rotation of the inlet that exists in the actual centrifugal compressor on the performance of the impeller, Apply Stodola's method of dealing with airflow slippage at the impeller outlet to the impeller inlet; 2) through the simplified peripheral velocity coefficient of the Euler equation in the original one-dimensional calculation method Correction is carried out, and a modified peripheral velocity coefficient is proposed 3) The peripheral speed coefficient will be corrected Directly correlate with impeller inlet and outlet diameter, impeller inlet and outlet blade installation angle, number of impeller blades, impeller speed and compressor flow parameters, deduce and propose a new one-dimensional impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com