A Algebraic Modeling Method of Circumferential Fluctuating Stress Term in Turbine Flow Model

A pulsating stress and modeling method technology, applied in CAD numerical modeling, special data processing applications, geometric CAD, etc., can solve problems such as insufficient reflection of flow field changes and insufficient design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

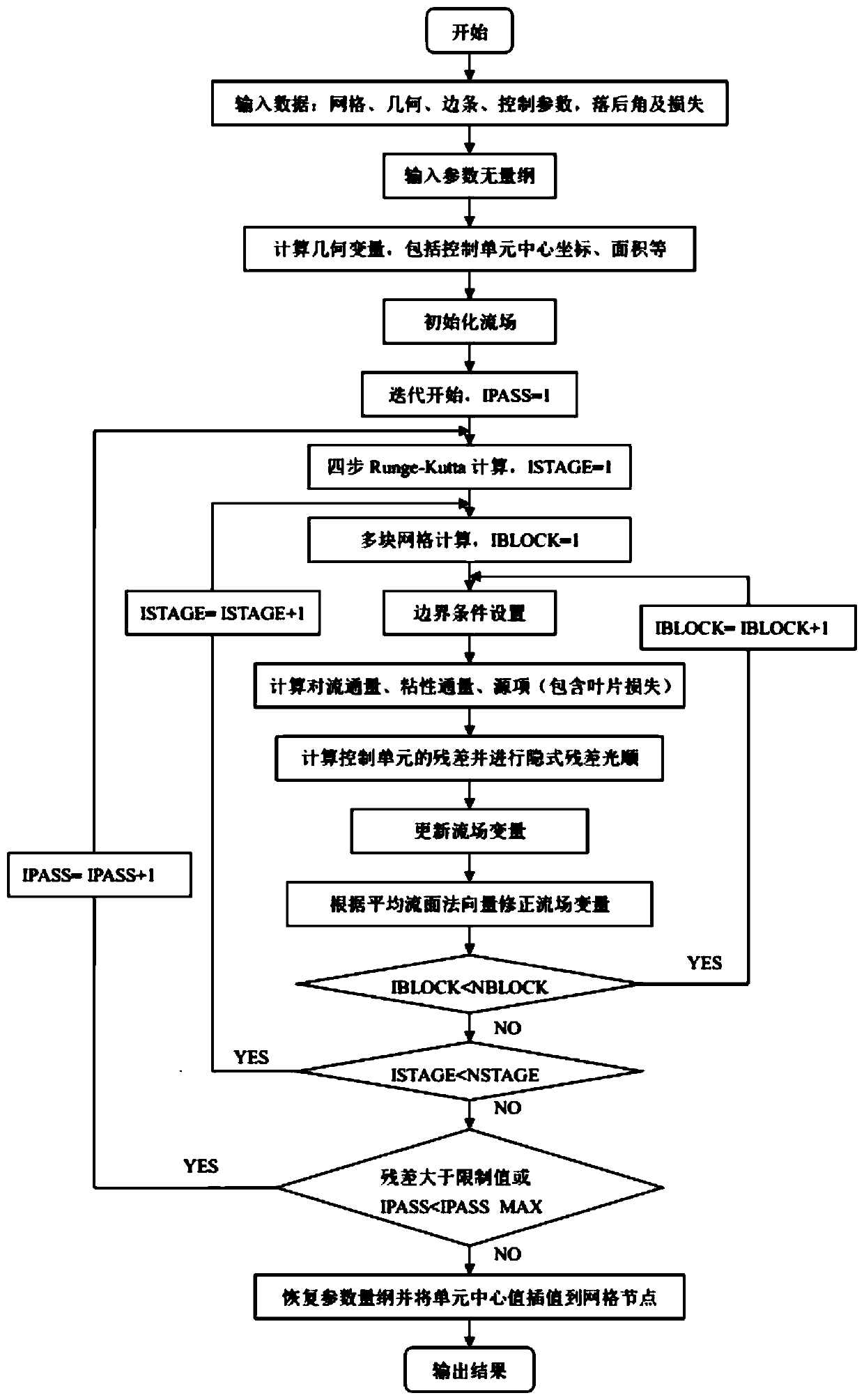

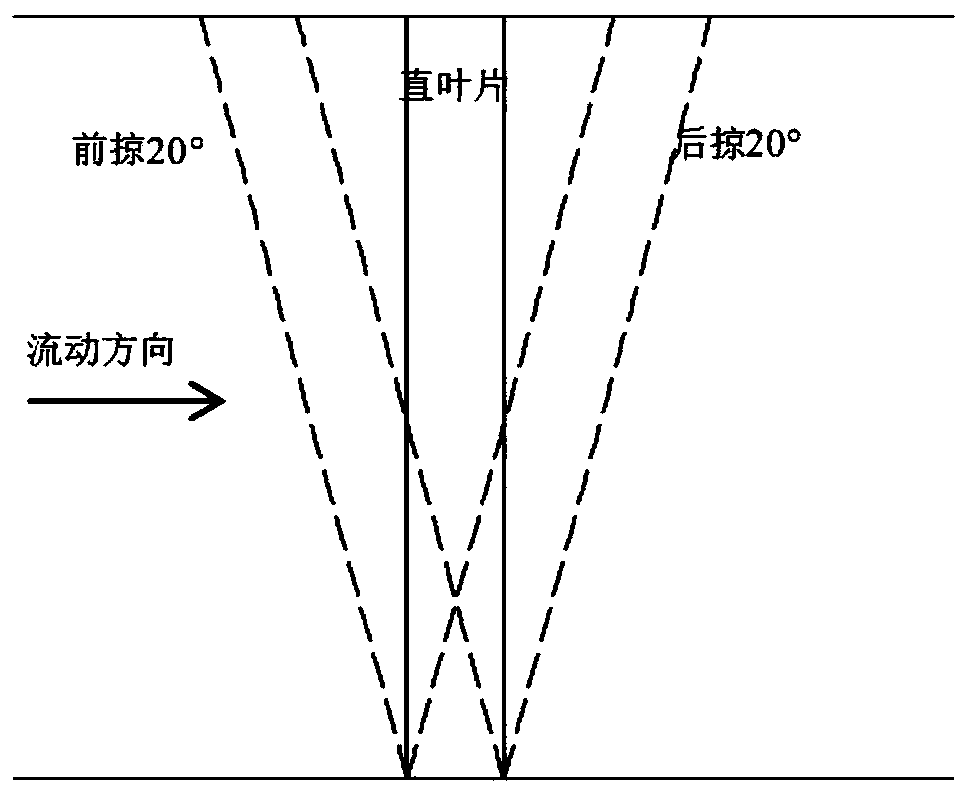

[0221] Example description:

[0222] Based on the flow software developed by our research group, combined with the algebraic modeling method of the circumferential fluctuating stress item in the turbine flow model proposed by the present invention, the influence of circumferential inhomogeneity in the cascade flow field is initially explored. Finally, the feasibility of the present invention is verified by comparative analysis with the results of three-dimensional numerical simulation.

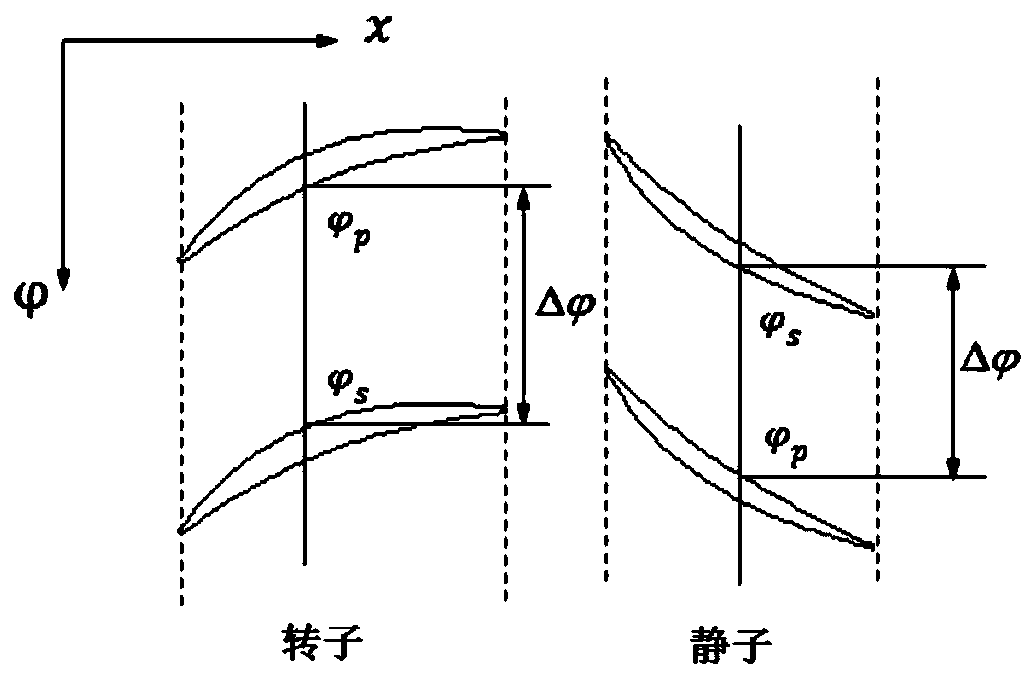

[0223] In view of the dimensionality reduction characteristics of the flow model due to the governing equations, the key techniques and difficulties in modeling the circumferential fluctuating stress item in the turbine flow model can be summarized as follows:

[0224] 1) The relationship between circumferential inhomogeneity and flow parameters in the average flow field

[0225] The calculation of the through-flow model is the average flow field after the circumferential average, which does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com