A bridge drive unit and an automobile lifting axle based on the bridge drive unit

A technology of drive unit and lifting bridge, which is applied in the direction of axles, wheels, vehicle parts, etc., can solve the problem that off-road vehicles cannot meet the needs of off-road conditions, and achieve the effect of preventing rotation and bending and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

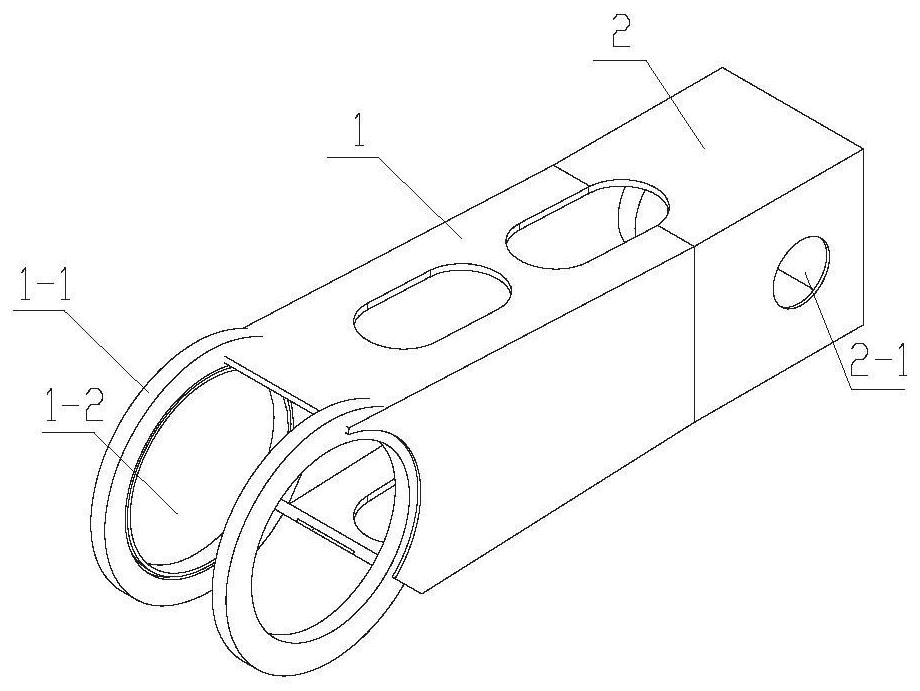

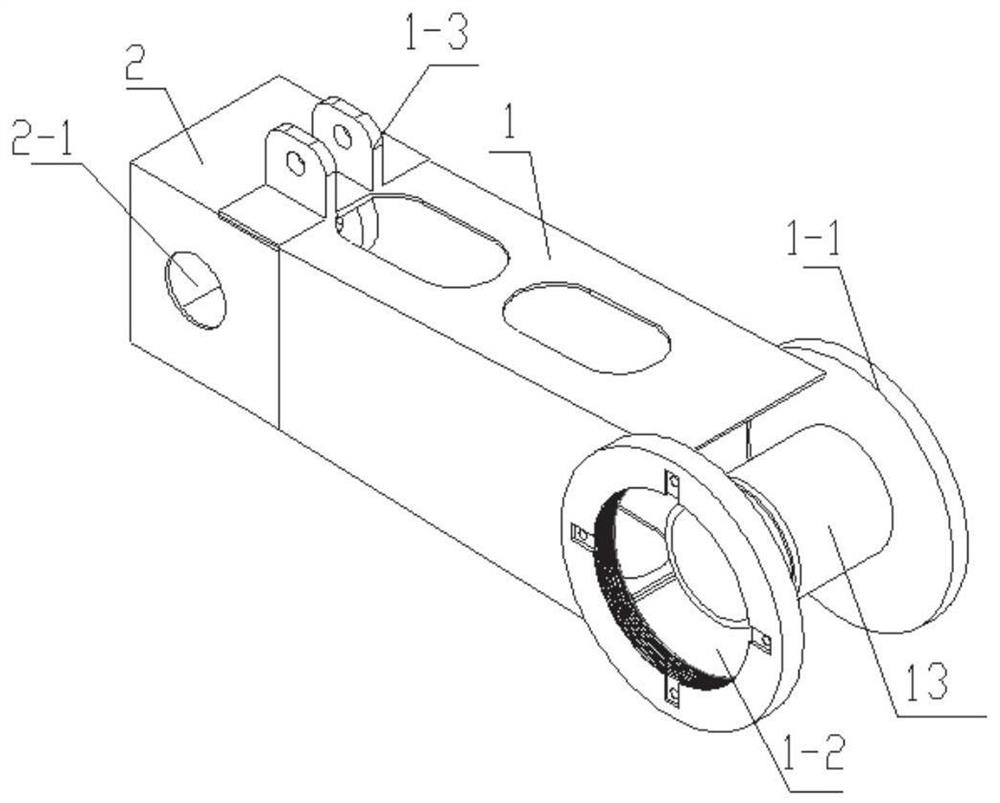

[0029] Such as figure 1 , figure 2 They are schematic diagrams of the structure of the axle box 1 and the countershaft box 2 of the axle drive unit respectively. In the field, the axle box 1 is also called the axle box. As a drive axle structure, one end of the axle box 1 is connected to the axle box 2, The other end symmetrically extends two circular connection plates 1-1, the connection plates 1-1 are parallel to each other and are provided with a circular hole 1-2 with a coaxial center, and the subshaft case 2 is also provided with a circular hole 2-1, the circular hole Two 2-1 are parallel to the axis of the circular hole 1-1.

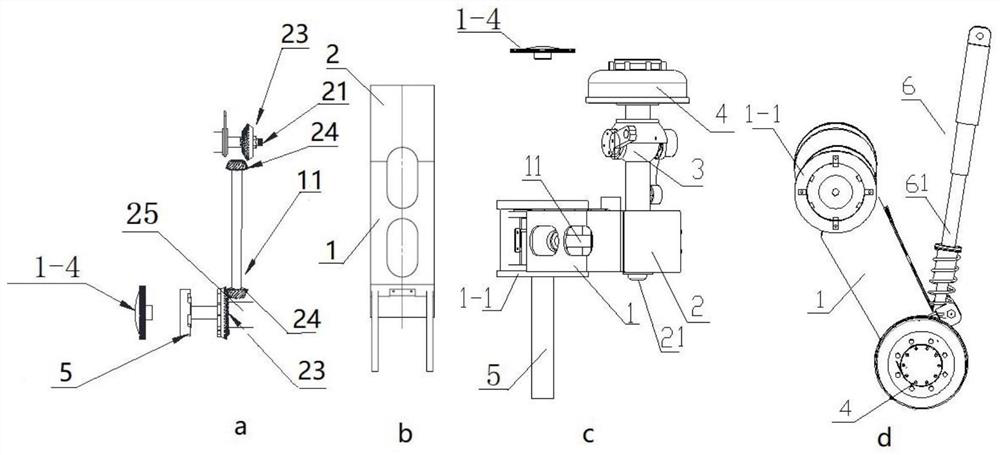

[0030] Such as image 3 a. image 3 b. image 3 c. A rotatable transmission shaft 11 is installed in the axle box 1. Both ends of the transmission shaft 11 are exposed from the axle box 1. A rotatable half shaft 21 is installed in the subshaft box 2. One end of the half shaft 21 extends out of the subshaft box 2. The hub 4 is driven by the un...

Embodiment 2

[0033] Such as Figure 5 It is the assembly drawing of the automobile front axle lifting axle based on the bridge drive unit, a pair of bridge drive units of embodiment 1 are symmetrically installed on one end of the main half shaft 5, and the transmission assembly includes the driving wheel 23 and the transmission on the main half shaft 5. The driven wheel 24 on the shaft 11, the surfaces of the driving wheel 23 and the driven wheel 24 are coupled to each other, the driving wheel 23 drives the driven wheel 24 on the two transmission shafts 11 to move in opposite directions, and the driven wheel 24 can be around the drive wheel 23 axis For planetary revolution, the driving wheel 23 and the driven wheel 24 are preferably pot gears 23 and bevel gears 24, but are not limited thereto. Such as Image 6, each auxiliary shaft box 2 is driven by the telescopic mechanism 6 on the same side, so that the two shaft boxes 1 rotate around the main half shaft 5 to form an included angle, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com