A control circuit for safe mite removal electric blanket that meets electromagnetic compatibility requirements

A technology of electromagnetic compatibility and control circuit, used in electric heating devices, ohmic resistance heating, blankets, etc., can solve the problems of human injury, high temperature in removing mites, etc., and achieve the effect of avoiding low-temperature scald or heat stroke injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

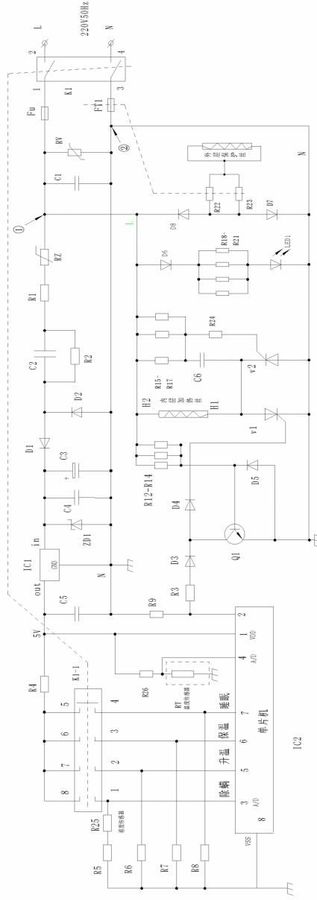

[0029] Such as figure 1 As shown, a safe anti-mite electric blanket control circuit that meets the requirements of electromagnetic compatibility includes a power supply circuit, a single-chip microcomputer control circuit, a trigger circuit, a power control circuit, and a double-pole single-throw structure. -1), protection circuit and display circuit; wherein the power circuit is connected with the single-chip control circuit and the trigger circuit; the single-chip control circuit is connected with the trigger circuit and the power control circuit; the switch K1-1 is connected with the single-chip control circuit; the switch K1 is connected with the power circuit, The power control circuit is connected to the trigger circuit; the display circuit is connected to the power circuit; the power circuit is connected to the heating element through the main thyristor V1 and the slave thyristor V2 in the power control circuit, and the protection circuit is connected to the power circui...

Embodiment 2

[0038] Such as figure 1 As shown, a safe anti-mite electric blanket control circuit that meets electromagnetic compatibility requirements includes a power supply circuit, a single-chip microcomputer control circuit, a trigger circuit, a power control circuit, and a double-pole single-throw structure. 1), protection circuit, display circuit.

[0039] The single-chip microcomputer in the single-chip microcomputer control circuit has preset control programs for four gears: mite removal, preheating, heat preservation, and sleep, among which:

[0040] Mite removal program: The average heating rate is 0.9°C / min, and the temperature rises to a constant temperature of 43°C. Measure the humidity at the same time as the temperature rises. When the humidity drops to 45%, continue to dehumidify at a constant temperature and start timing. After 100 minutes, start to cool down: the cooling rate is 1°C every 15 minutes until it drops to 36°C. Keep the temperature constant and dry, and set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com