Multifunctional final impression device, using method and digital complete denture manufacturing method

A multi-functional, impression technology, which is applied in compression cups, medical science, dentistry, etc., can solve the problems of difficulty in making accurate impressions and the positional relationship between upper and lower jaws, single function, inconvenient use, etc., to achieve impression taking and determination The effect of accurate upper and lower jaw relationship, simplified operation and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The first embodiment of the present invention is to provide a multifunctional final impression device, the purpose of which is to quickly and accurately take the final impression of edentulous patients and obtain an accurate median relationship. Through the combination of modules, multiple functions can be realized, which greatly simplifies the The doctor's operation, taking impressions and determining the relationship between the upper and lower jaws are more accurate, which can effectively improve the quality of the complete denture and ensure the accuracy of the final restoration.

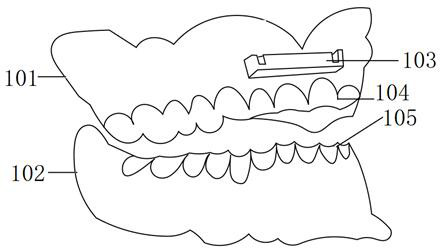

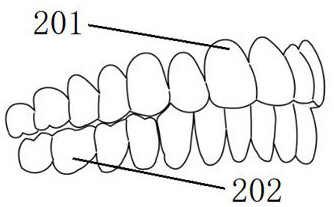

[0059] like Figure 1-2 As shown, in the first aspect, a multifunctional final impression device, which includes a maxillary base 101, a mandibular base 102, a maxillary dentition 201, a mandibular dentition 202, and an external interface 103. The bottom of the maxillary base 101 is provided with There is a maxillary dentition interface 104 matching the maxillary dentition 201, and the to...

Embodiment 2

[0068] In the second aspect, a method for using the multifunctional final impression device of the first aspect, which includes the following steps:

[0069] Step 1: install the maxillary dentition 201 and the mandibular dentition 202 in the maxillary base 101 and the mandibular base 102 respectively;

[0070] Step 2: After placing silicone rubber on the surface of the maxillary base 101 and the mandibular base 102, put the upper jaw base 101 and the mandibular base 102 into the patient's mouth as a whole, let the patient occlude the upper and lower jaws, and obtain the closed mouth in the occlusal state impression;

[0071] Step 3: Determine whether the occlusal position relationship between the upper and lower dentition of the closed mold is accurate:

[0072] If the occlusal relationship is inaccurate, separate the maxillary dentition 201 and the mandibular dentition 202 from the maxillary base 101 and the mandibular base 102 respectively, so that a dentition gap is left b...

Embodiment 3

[0080] like Figure 7-9 As shown, in a third aspect, a method for making a digital complete denture, which includes the following steps:

[0081] Step 1: Use the centric jaw tray and initial impression to obtain the centric relationship of the whole mouth;

[0082] Step 2: Scan the initial impression and the central jaw tray or scan the plaster model of the initial impression and the central jaw tray, match the data of the initial impression and the central jaw tray, and obtain the initial impression and occlusal relationship data;

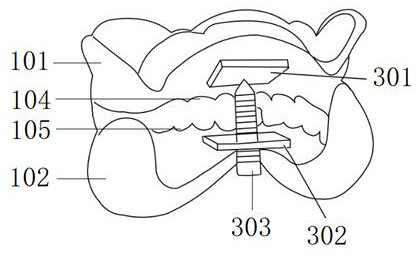

[0083] Step 3: Design the multifunctional final impression device of Example 1; the multifunctional final impression device includes a maxillary base 101, a mandibular base 102, a maxillary dentition 201, a mandibular dentition 202, a maxillary trace, a locator 502, a mandibular Positioning plate 302, positioning pin 303, 3D printing multifunctional final impression device;

[0084] Step 4: Confirm the relationship between the closed impression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com