Device for floatably removing burrs at threaded inlets and outlets

A technology for entrance and exit and deburring, which is applied in the field of machining devices, can solve the problems of tooth tip deformation, low removal efficiency, and low quality of threaded tails, and achieve the effect of stable and reliable cooperation, economical reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

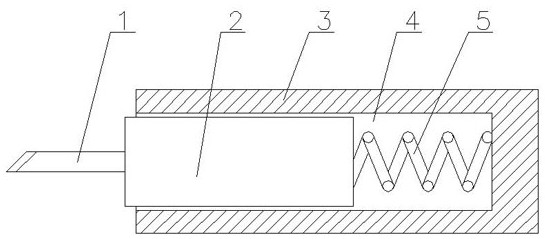

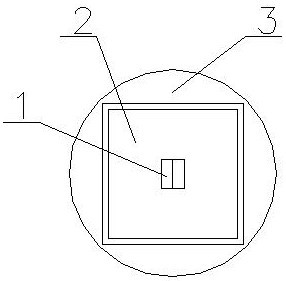

[0016] The specific implementation, structure, features and functions of the device for floating and deburring threaded inlets and outlets according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

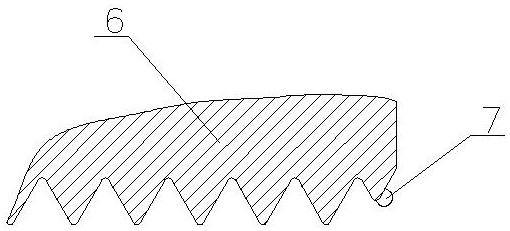

[0017] see Figure 1 to Figure 2 , the floating deburring device of the threaded inlet and outlet of the present invention includes a countersinking boring tool 1, a sleeve 3, and a spring 5, wherein: the countersinking boring tool 1 is fixedly connected to the tool bar 2, and the tool bar 2 is placed on the sleeve 3 In the provided installation cavity 4 , a spring 5 is installed between the tail end surface of the knife bar 2 and the inner wall end surface of the sleeve 3 , and an installation gap is provided between the outer surface of the knife bar 2 and the inner surface of the sleeve 3 . Tool holder 2 is a cuboid cutter holder. The installation cavity 4 is a cuboid cavity matched with the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com