Edge sealing device capable of operating at high speed, edge sealing method, packaging machine and packaging method

An edge banding device and high-speed technology, applied in the direction of transportation and packaging, transportation packaging, packaging, etc., can solve the problems affecting the appearance quality of product packaging, texture superimposition, and low machine operation efficiency, so as to improve operation efficiency, increase operation speed, The effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

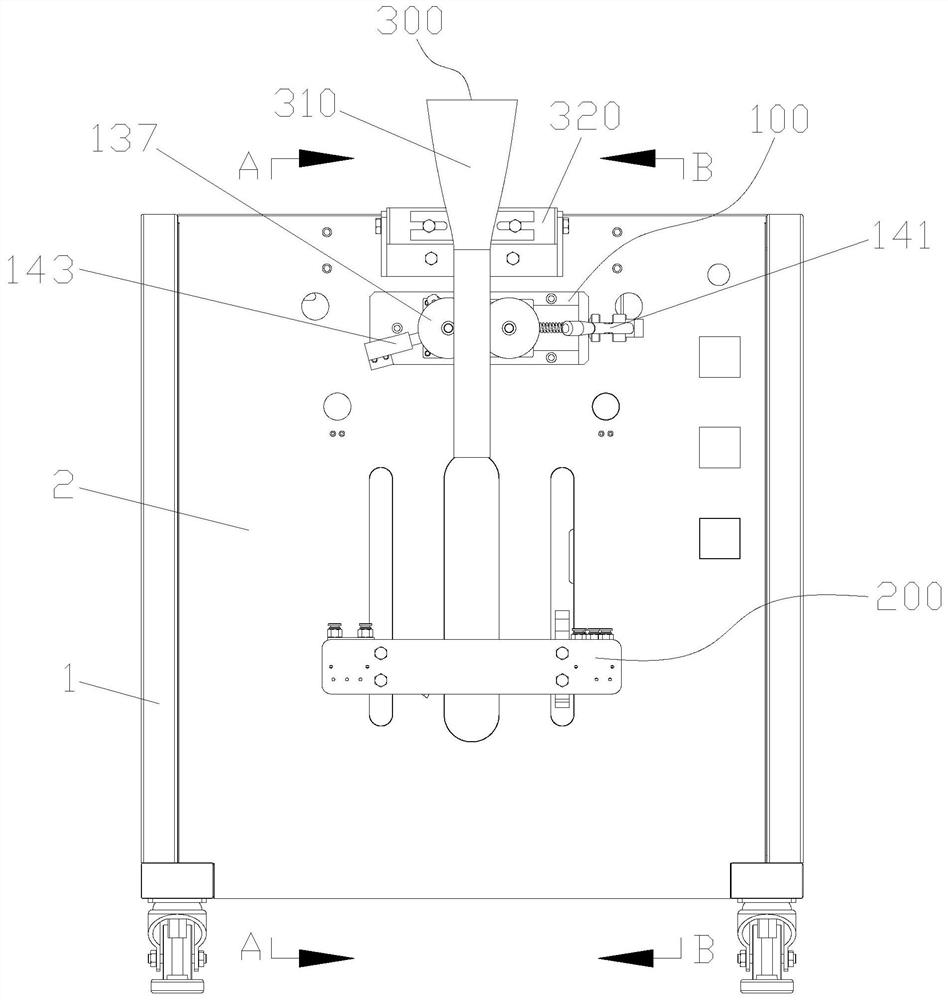

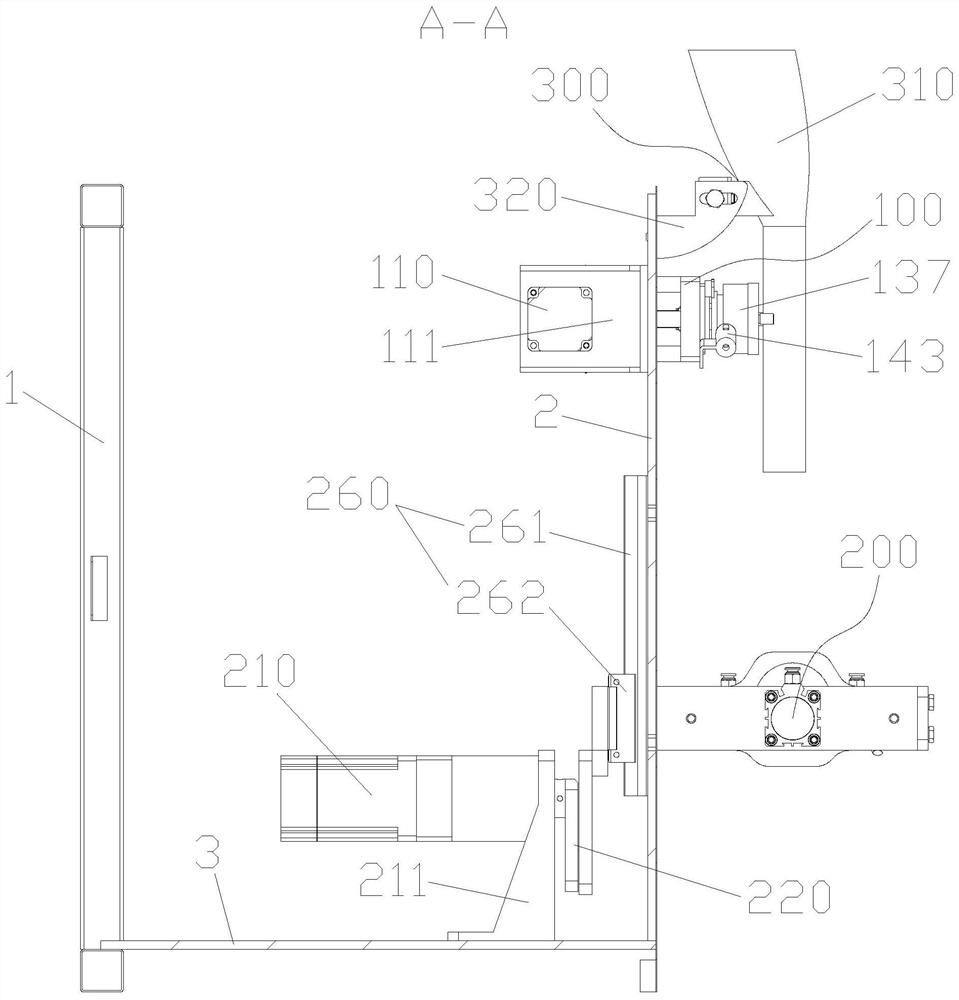

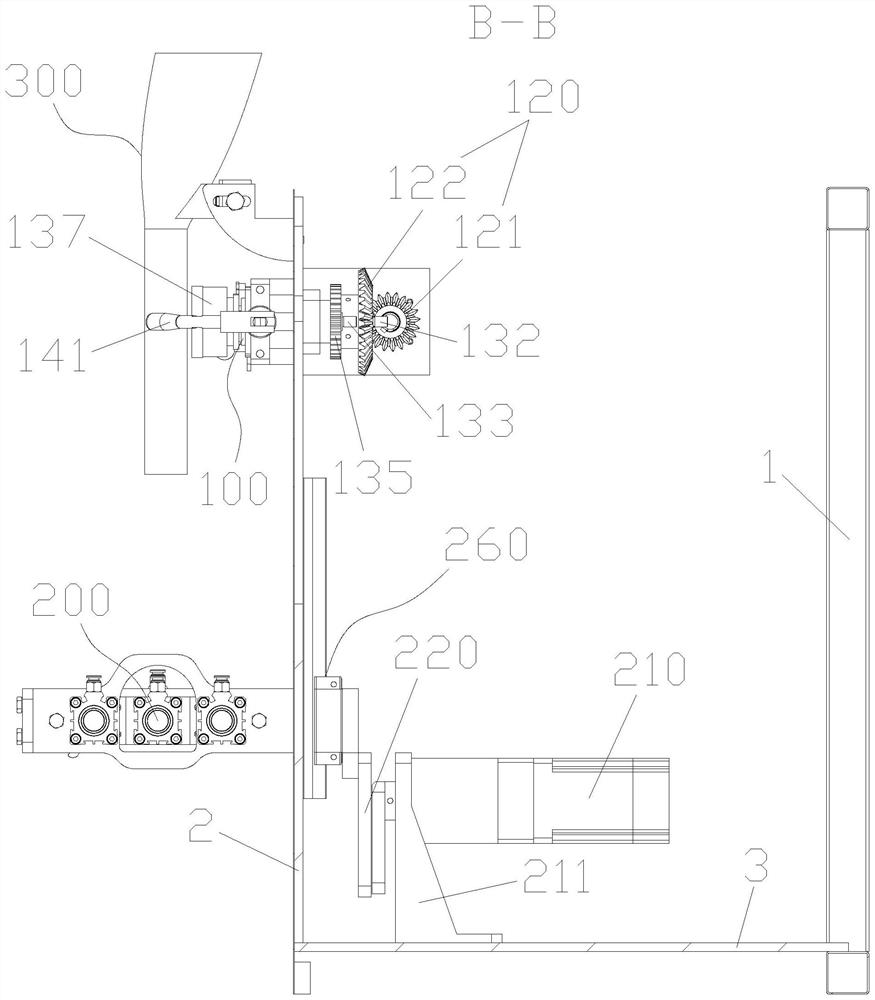

[0037] Embodiment one: if Figure 1-10 As shown, an edge banding device capable of high-speed operation includes a longitudinal sealing film pulling device 100 and a horizontal sealing clamping device 200 distributed sequentially from top to bottom, and the longitudinal sealing film pulling device 100 includes a first motor 110, a second A transmission mechanism 120 and a vertical sealing edge pulling film mechanism 130, the output shaft of the first motor 110 drives the vertical sealing edge pulling film mechanism 130 to work through the first transmission mechanism 120, and the vertical sealing edge The film pulling mechanism 130 includes two vertical edge sealing and pulling film pulleys 137 for heating and sealing and pulling the film; mechanism 230, the output shaft of the second motor 210 drives the horizontal sealing edge sealing and pulling mechanism 230 to work through the second transmission mechanism 220, and the horizontal sealing edge sealing and pulling mechanism...

Embodiment 2

[0053] Embodiment two: if Figure 1-10 As shown, a packaging machine capable of high-speed operation includes the edge banding device capable of high-speed operation in the first embodiment above. In addition, the packaging machine also includes a forming and blanking device 300, the forming and blanking device 300 includes a former 310 and a forming fixture 320, and the former 310 is used for folding a single-layer packaging film into a double-layer packaging film and For blanking, the former 310 is fixedly installed on the front surface of the front plate 2310 of the frame 1 through the forming fixture 320, and the feeding end of the former 310 is located above the longitudinal sealing film pulling device 100, so The discharge end of the former 310 is located between the longitudinal sealing film pulling device 100 and the horizontal sealing pinching device 200 .

[0054] In this example, if Figure 1-10 Shown, the packaging method of the packaging machine capable of high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com