Rim charge removing and loading mechanism for protective plate

A protection board and pressing board technology, which is applied in the direction of conveyor objects, feeding devices, positioning devices, etc., can solve the problems of scattered and disordered protection boards, time-consuming sorting, and low efficiency, so as to save overall processing time and avoid pollution , Optimize the effect of the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

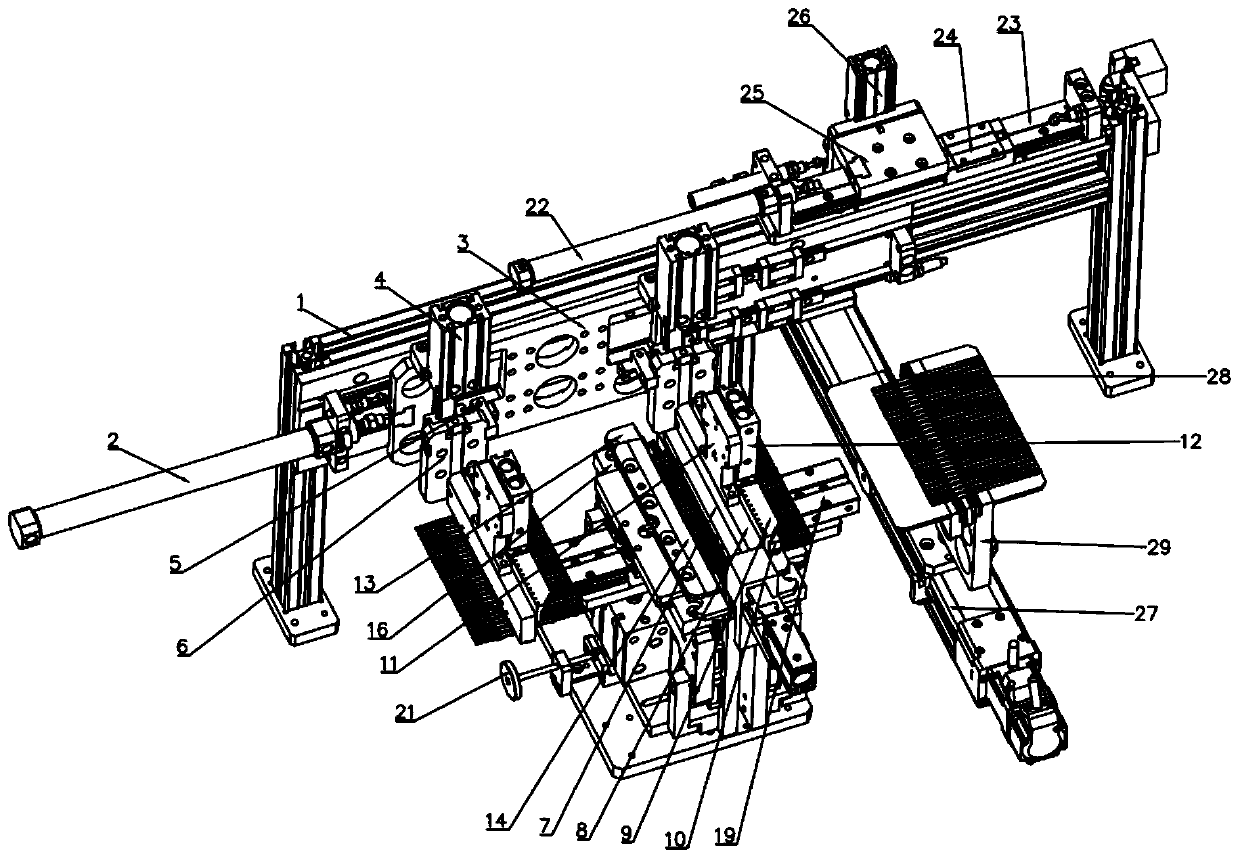

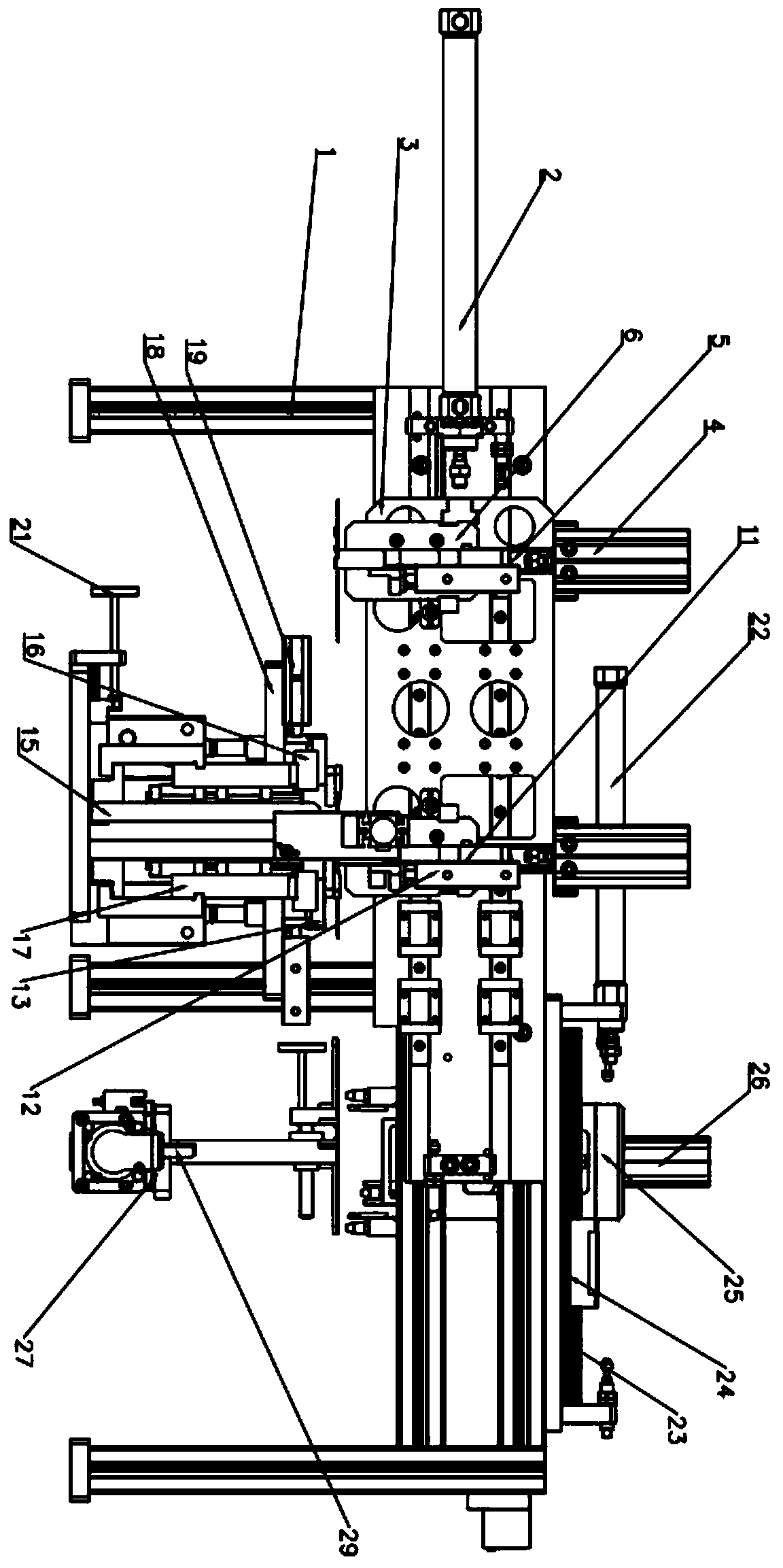

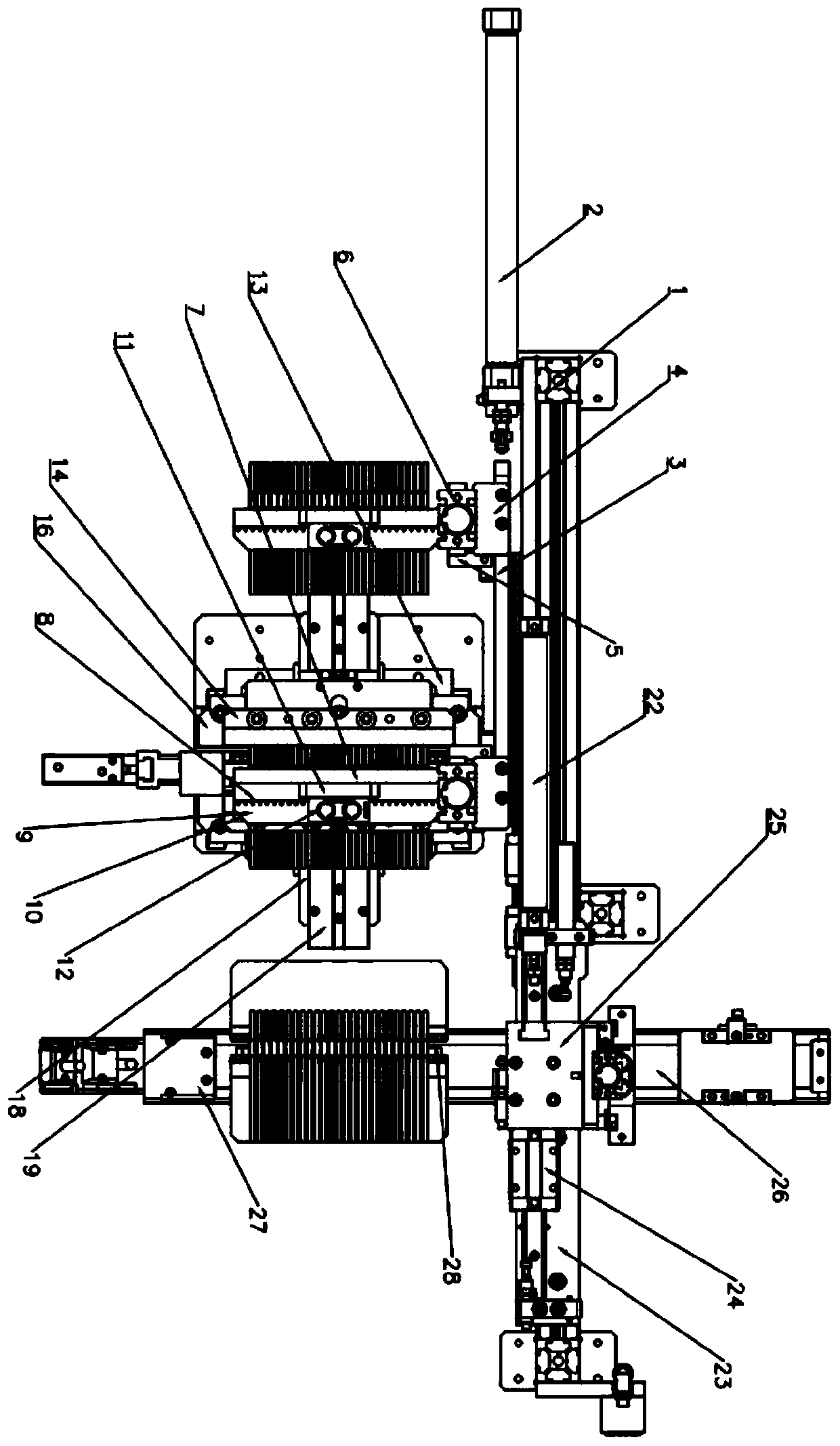

[0033] Example: When the device is in operation, the nickel sheet guide and hemming module is fixed with screws on the top of the protective plate trimming and rewinding module 13, and the bevel side of the nickel sheet guide and hemming module 14 forms a bayonet with the protective plate trimming module. , When the protective circuit board is placed on the protective plate supporting plate 16 by the magnetic lifting mechanism, the nickel sheet guide and folding module 14 and the protective plate trimming module are pushed inward with the folding fixed cylinder 19. During the process, because the nickel sheet is above the protection circuit board, the oblique opening of the edge removal module of the protection board is slightly lower than the nickel sheet, so the nickel sheet will tilt up along the oblique edge, and then use the bayonet to clamp the edge material connection of the protection board Afterwards, the folding cylinder 20 moves up and down to realize automatic foldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com