Compensator mounting adjusting device and compensator site mounting method

A technology for installing adjustments and compensators, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve the problem of shrinking the usable temperature area, processing pipeline deformation compensation, and reducing the use of compensators Life and other issues, to achieve the effect of improving stability and firmness, ensuring service life and reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

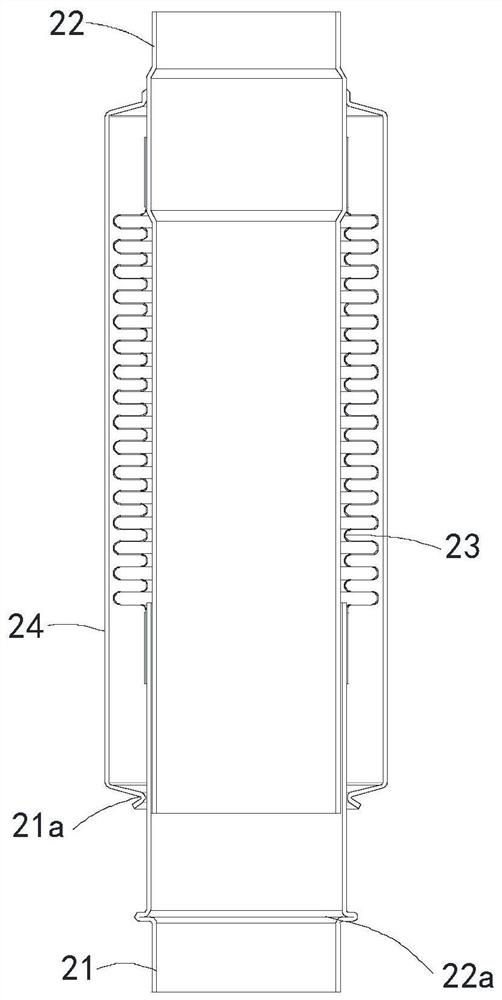

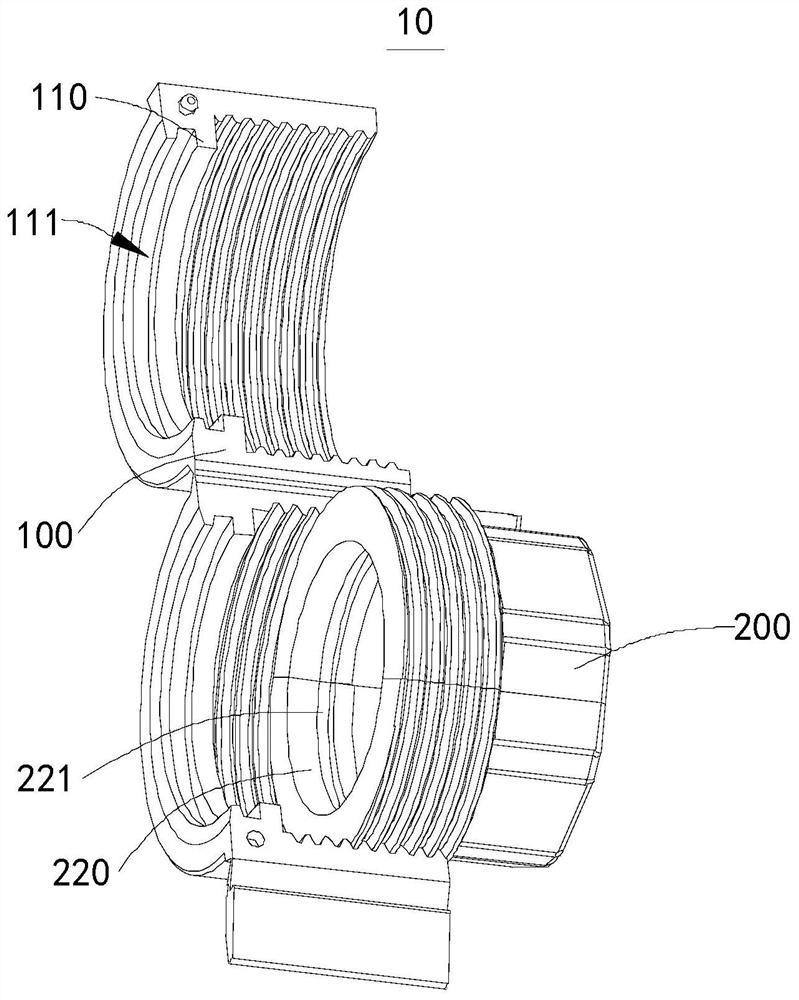

[0038] Please refer to Figure 1 to Figure 9 , a compensator installation and adjustment device, matched with the compensator, the compensator includes an outer casing, an inner conduit, an elastic expansion tube and a protective sleeve, one end of the inner conduit extends into the outer casing, the outer casing is set at one end of the inner conduit, and the inner conduit The elastic telescopic tube is sleeved at the other end of the inner conduit, and the two ends of the elastic telescopic tube are respectively welded to the outer sleeve and the inner conduit. The compensator is also equipped with a protective cover, which encloses the elastic flexible tube Setting, one end of the protective sleeve is welded to the inner conduit, and the other end is slidingly fitted with the outer sleeve. The compensator installation adjustment device includes an outer ring sleeve and an inner ring sleeve. The outer ring sleeve is connected to one end of the outer sleeve, and the inner ring...

Embodiment 2

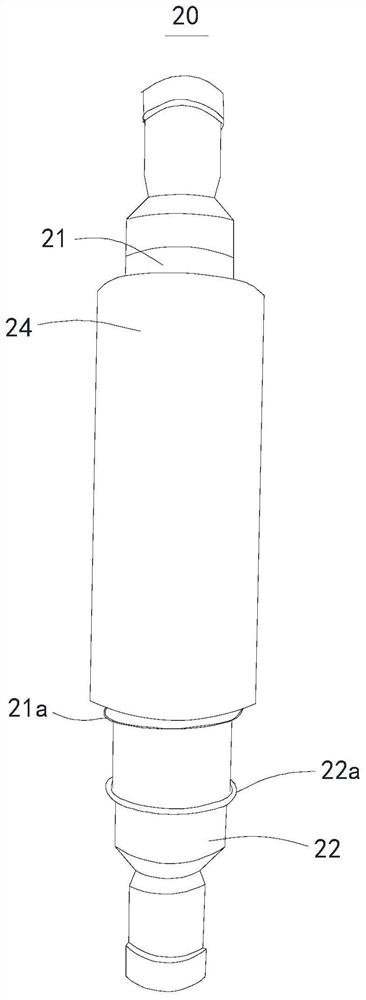

[0058] This embodiment is to provide various compensator structural forms that can be used by the compensator installation and adjustment device.

[0059] Please refer to Figure 10 , the compensator includes an outer tube, an inner tube, an elastic telescopic tube and a protective sleeve. A section of the inner tube extends into the guide tube, and the outer tube is set on a section of the inner tube. The inner tube and the outer tube are connected by sliding fit, and the elastic tube Set on the other end of the inner conduit, the two ends of the elastic telescopic tube are welded to the outer casing and the inner conduit respectively. Snug fit with inner catheter.

[0060] The compensator installation and adjustment device includes an outer ring sleeve and an inner ring sleeve. The outer ring sleeve is connected to one end of the outer casing, the inner ring sleeve is connected to one end of the inner conduit, the outer ring sleeve is set on the outer wall of the inner ring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com