Method and device for diagnosing flow ignition combustion process and details of metal particles

A technology of combustion process and metal particles, which is applied in the direction of measuring devices, chemical analysis by combustion, engine testing, etc., to achieve the effect of promoting and inhibiting condensed phase deposition in research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

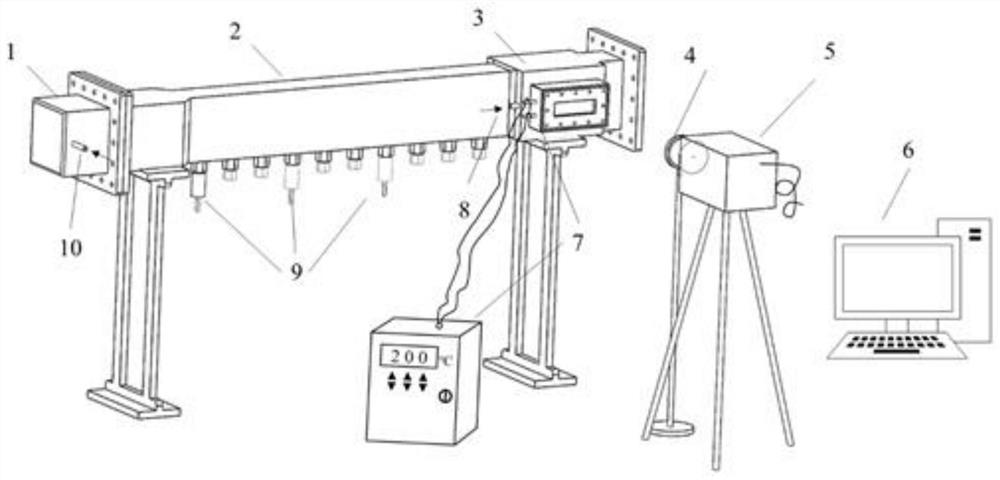

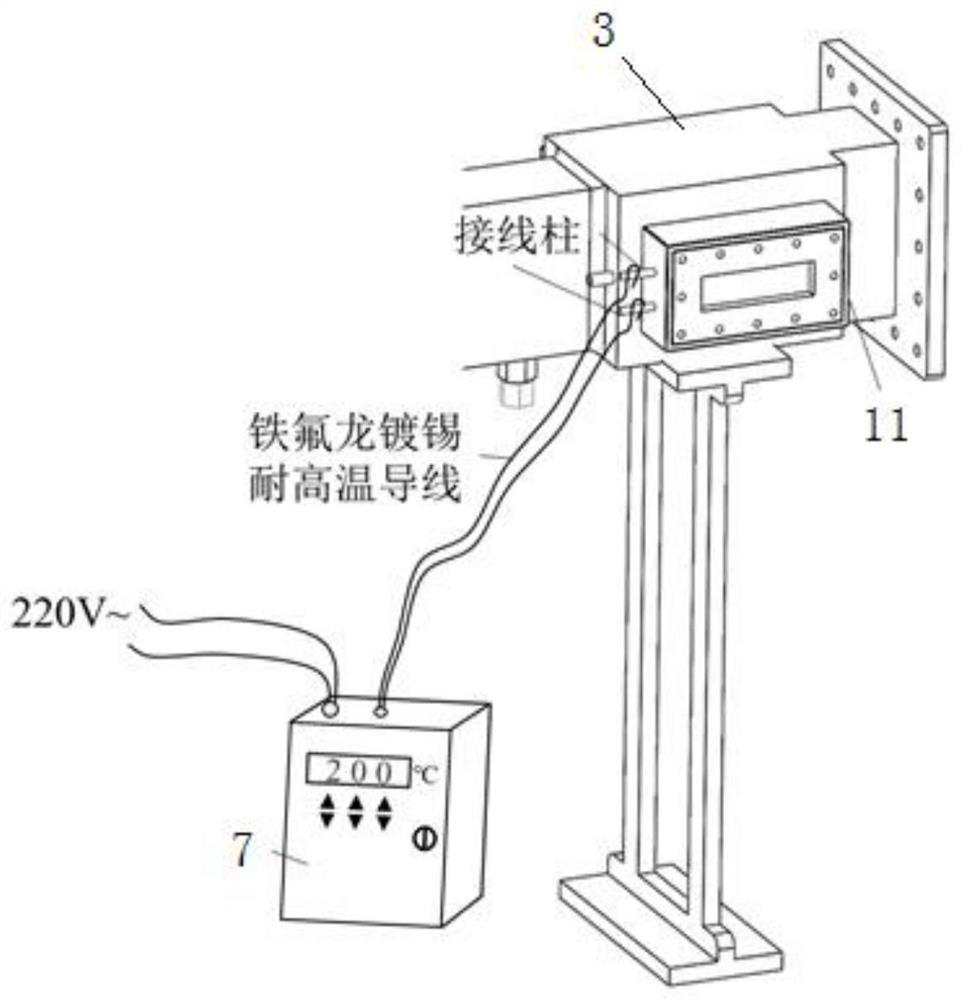

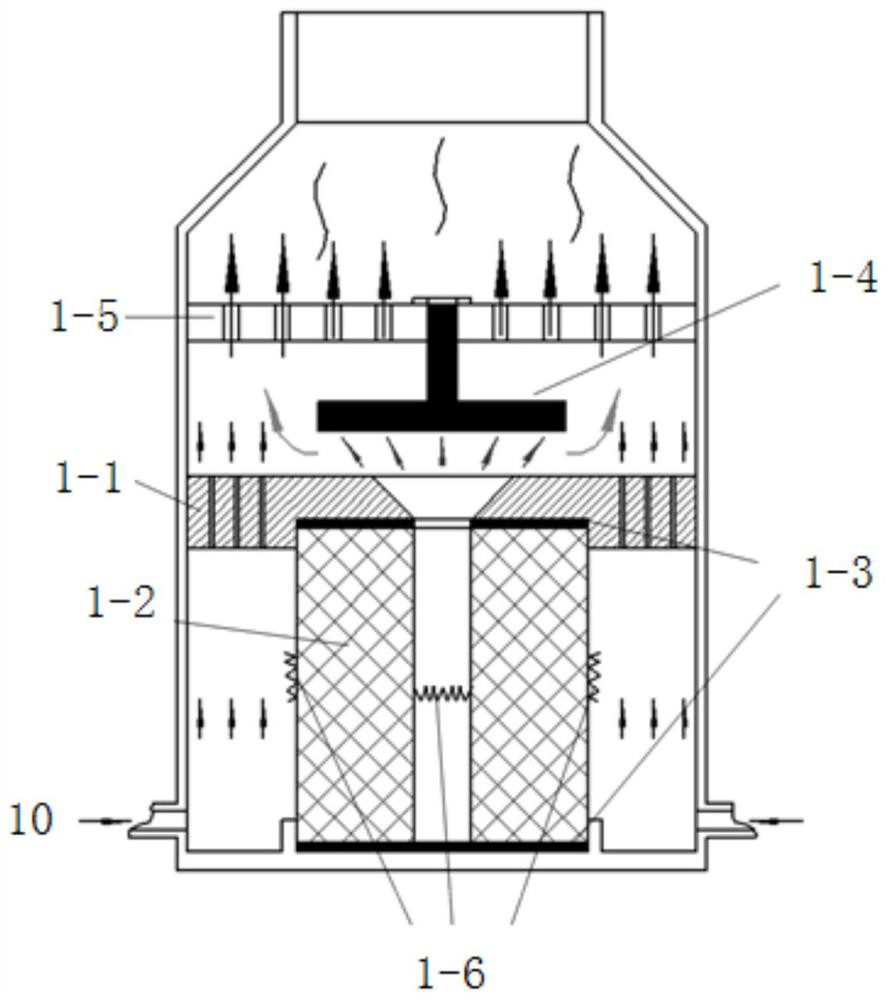

[0034] Such as figure 1 and 2 As shown, a diagnostic device for the combustion process and details of metal particles flowing with the flow, including a solid gas generator 1, a gas channel 2 and a window observation section 3 connected in sequence in the axial direction, the gas channel 2 is a shell The enclosed cavity is provided with a plurality of longitudinal powder ejectors 9 at intervals along its length on the lower shell of the gas passage 2, and the plurality of powder ejectors 9 do not work at the same time, and are used for Inject the metal powder into the gas channel 2. The particles injected by the powder catapult 9 at different positions will be in different ignition and combustion stages when they reach the observation window, and the high-speed camera 5 collects information such as the flow state and flame structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com