Electric power engineering distribution box

A power engineering and distribution box technology, applied in electrical components, substation/switch layout details, busbar/line layout, etc., can solve problems such as hidden safety hazards, limited distribution box space, inconvenient wiring operations, etc., to avoid wiring errors , to avoid cross confusion, and to facilitate the effect of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

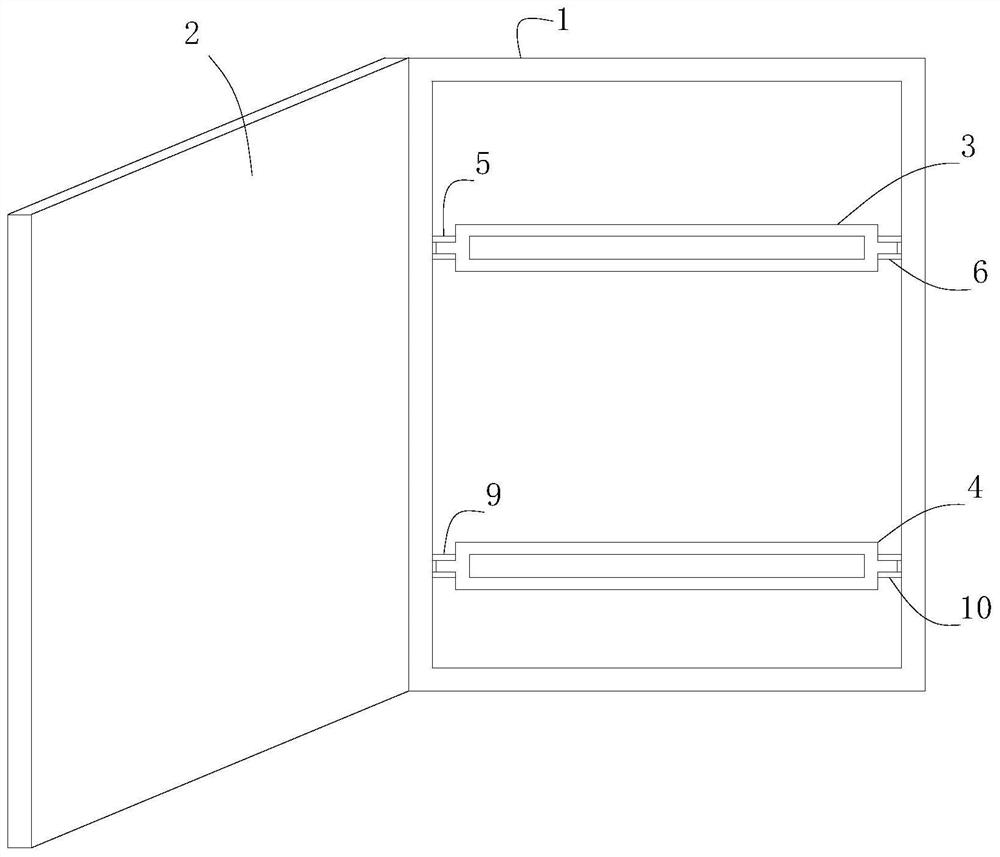

[0015] Reference Figure 1-Figure 3 , The present invention proposes a power engineering distribution box, including a box body 1 and a box door 2 connected to the box body 1; the box body 1 is installed with upper and lower wiring components arranged up and down; wherein:

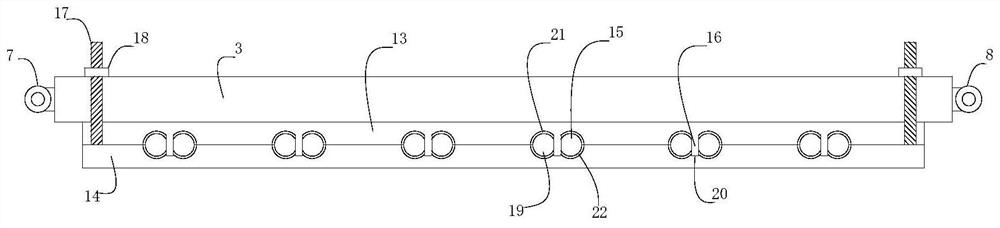

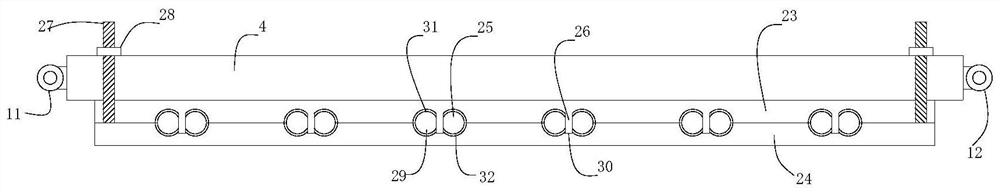

[0016] The inner wall of the box body 1 is equipped with a first upper guide rail 5 and a second upper guide rail 6 arranged in parallel and oppositely and in the same horizontal plane. The first upper guide rail 5 and the second upper guide rail 6 are both perpendicular to the door 2 and the first upper guide rail 5 The end of the second upper guide rail 6 close to the door 2 is a free end. The inner wall of the box body 1 is also installed with a first lower guide rail 9 and a second lower guide rail 10 arranged in parallel and oppositely and in the same horizontal plane. The first lower guide rail 9 and the second lower guide rail 10 are both perpendicular to the door 2 and the first lower guide rail 9. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com