Sliding equipment

A technology of equipment and pulley, applied in the field of sliding equipment, can solve the problems of heavy workload of staff and increase of equipment cost, and achieve the effect of good braking effect, reduction of construction cost, and safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

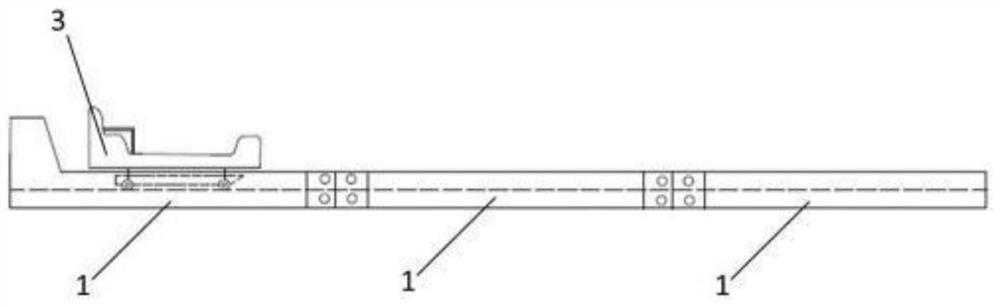

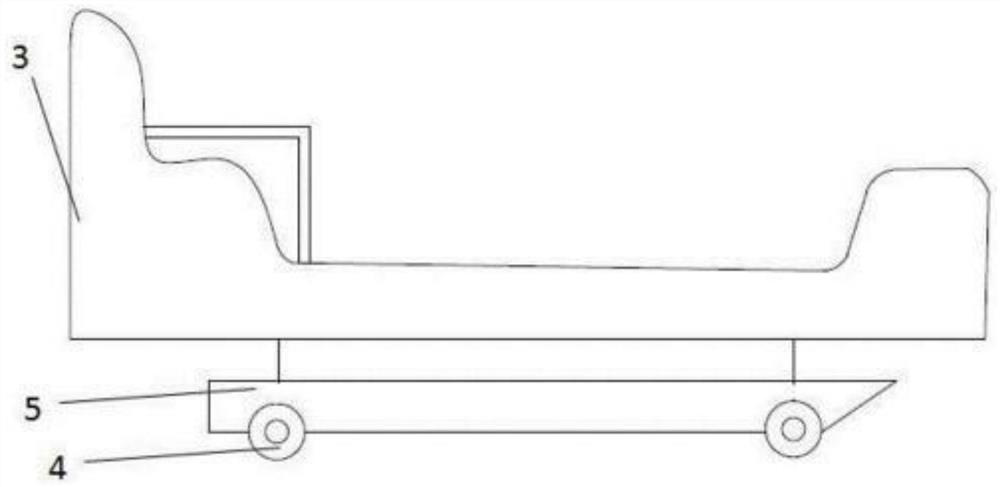

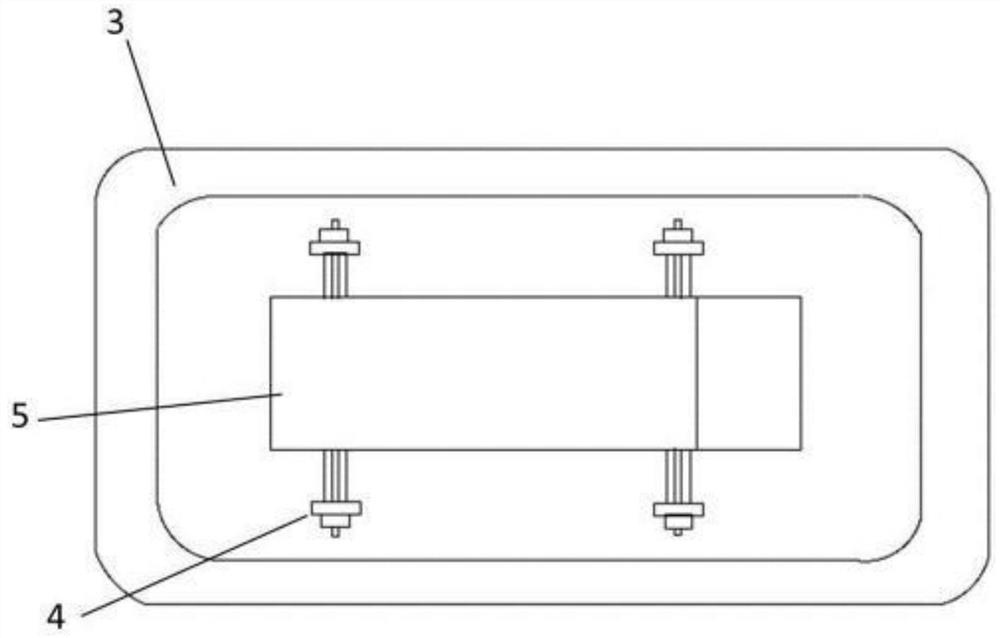

[0052] Such as Figure 1 to Figure 14 As shown, the present invention provides a sliding device, including a slideway and a pulley used in conjunction with the slideway; at least one pulley.

[0053] The slideway includes two rails 1 and at least one connecting bracket 2, at least one of the connecting brackets 2 is used to connect the two rails 1; the two rails 1 are parallel to each other, and the opposite one of the two rails 1 Each side has rail runners respectively.

[0054] Such as Image 6 with Figure 7 As shown, the track 1 includes a top wall 12, a side wall 13 and a bottom wall 14, one end of the bottom wall 14 is connected to the bottom end of the side wall, and the other end of the bottom wall 14 extends upwards and then approaches the side wall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap