Electromagnetic locking differential mechanism

A differential and electromagnetic lock technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as inability to get out of trouble, slipping, and insufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

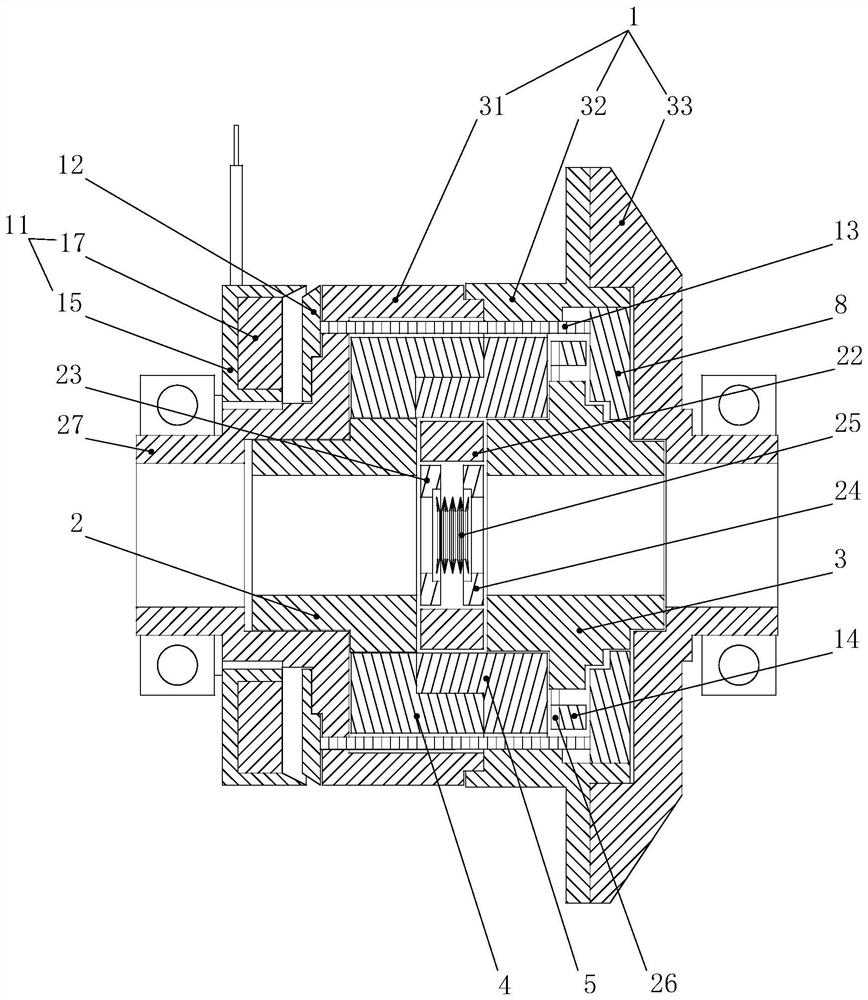

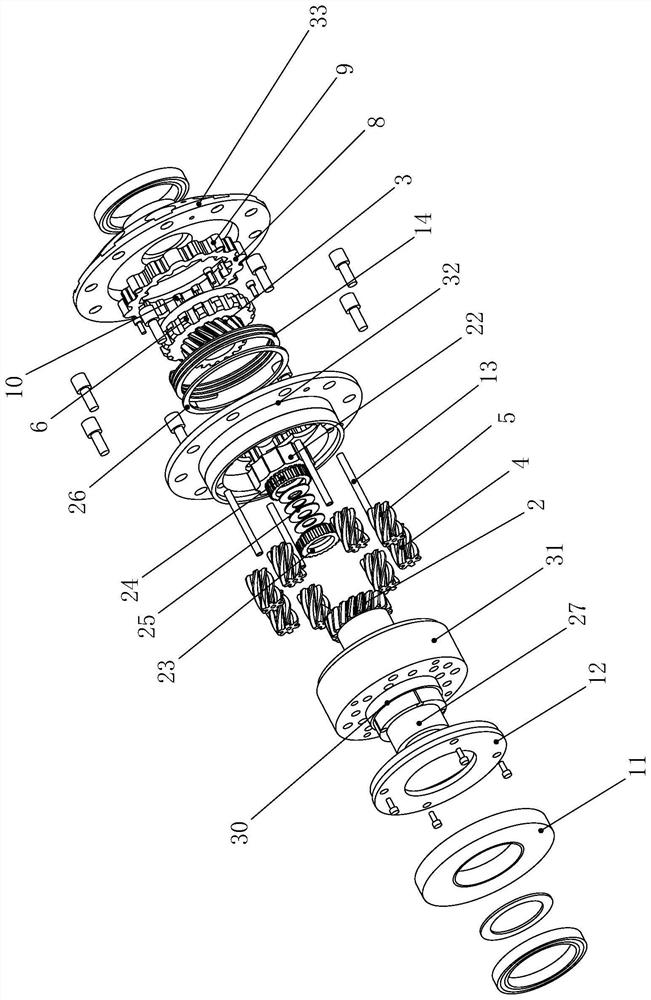

[0026] The present invention will be further described below with specific embodiment, see figure 1 -7:

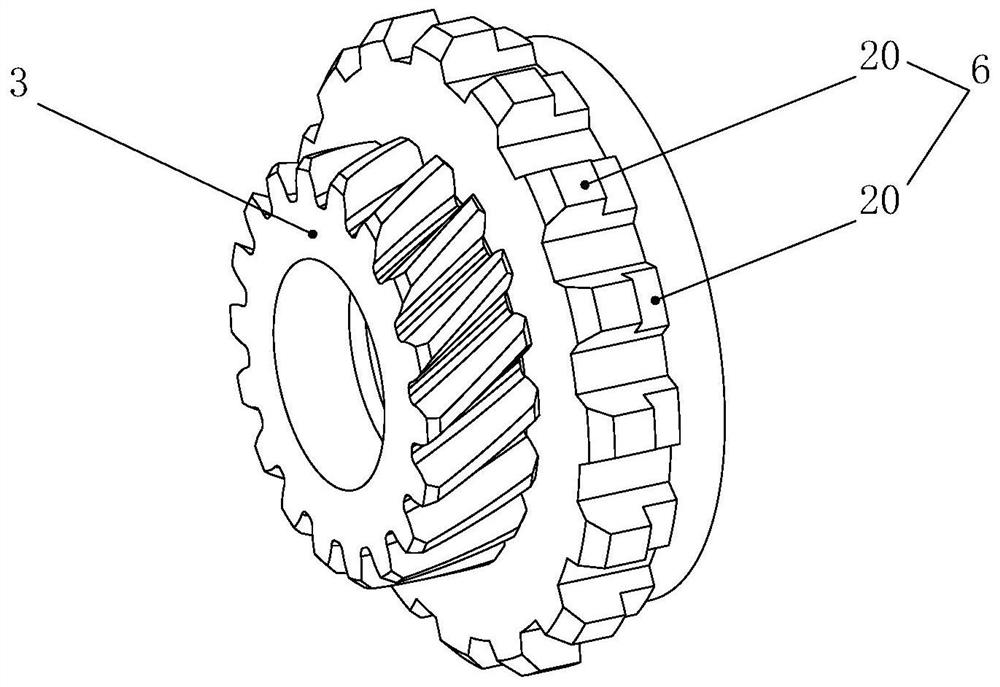

[0027] An electromagnetic locking differential, comprising a housing 1 with a chamber, the chamber is rotatably connected with a front half shaft helical tooth 2, a rear half shaft helical tooth 3, a front planetary gear 4 meshing with the front half shaft helical tooth 2, As well as the rear planetary gear 5 meshed with the rear axle helical gear 3, the front planetary gear 4 corresponds to and meshes with the rear planetary gear 5 one by one. Among them, a set of planetary gear sets are formed between the front helical gear 2 , the front planetary gear 4 and the housing 1 , and between the front helical gear 2 , the front planetary gear 4 and the housing 1 .

[0028] And be positioned at the side wall of rear axle shaft helical tooth 3 of described rear planetary gear 5 rear side and offer meshing tooth-6, the inner side wall of chamber is provided with straight tooth-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com