Rainwater collection cellar multistage desilting system

A water cellar and sedimentation technology, which is applied in waterway systems, sedimentation tanks, sedimentation separation, etc., can solve the problems of insufficient rural water supply, farmers' water use, reduced water storage capacity of water cellars, and no buffering of flow rate, etc. The hidden danger of silting, reducing the dredging of water cellars, and improving the effect of security

Pending Publication Date: 2020-10-16

YUNNAN AGRICULTURAL UNIVERSITY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

According to the survey, most of the water cellars in mountainous areas currently have serious sedimentation, shortened service life of water cellars, difficulties in later maintenance, and water storage capacity of water cellars is decreasing year by year, which cannot meet the needs of rural water supply and farmers' water use

[0004] At present, most mountainous rural rainwater cellars do not have sand settling and filtering facilities. The sand settling facilities of some water cellars use two rectangular settling tanks for sand settling. When the rainwater converges, the water flows directly into the settling settl

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

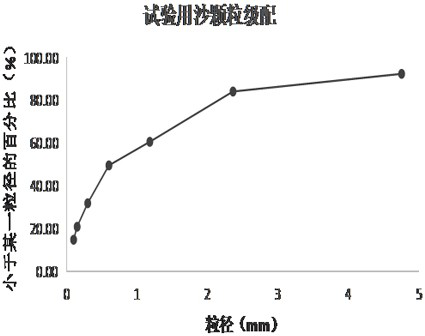

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

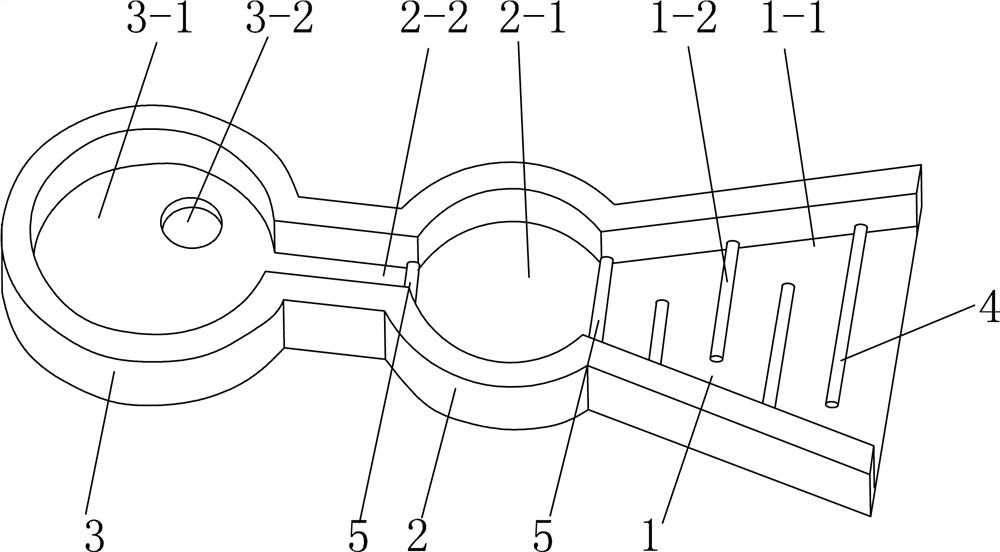

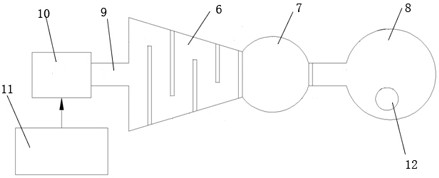

A rainwater collection cellar multistage desilting system comprises a first-stage desilting tank, a second-stage desilting tank and a third-stage desilting tank. The first-stage desilting tank comprises a horn-shaped tank body, the large end of the horn-shaped tank body is in the water inlet direction, and a labyrinth type buffer structure is arranged on the inner bottom surface of the horn-shapedtank body. The second-stage desilting tank comprises a first circular tank body, and the left end and the right end of the first circular tank body are communicated with the first-stage desilting tank and the third-stage desilting tank through water passing openings respectively. The third-stage desilting tank comprises a second circular tank body; the second circular tank body is mounted at thetop of the cellar and is communicated with the cellar through a cellar water inlet. The rainwater collection cellar multistage desilting system improves the utilization rate of a cellar and prolongs the service life of the cellar.

Description

technical field [0001] The invention relates to a rain-collecting water cellar, in particular to a multi-stage sedimentation system for a rain-collecting water cellar, which is suitable for a water cellar or a small pool for collecting rain and storing water on slopes or soil roads in rural areas in mountainous areas. Background technique [0002] The total amount of water resources in my country is large, but the per capita share is small. Due to the uneven distribution of precipitation in time and space, the overall land area is mostly mountainous, and the problem of water resource shortage is becoming more and more serious, especially in mountainous areas. According to the survey, some rural people in mountainous areas mostly use rainwater collection to store drinking water and irrigation water sources, and water cellars are one of the important means to solve water sources in mountainous rural areas. According to statistics, the rural population decreased by 140 million ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D21/02B01D21/00E03F5/14

CPCB01D21/0036B01D21/0066B01D21/02E03F5/14

Inventor 尹亚敏彭尔瑞罗富成范春梅

Owner YUNNAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com