Lifting type rescue method

A lifting oil cylinder and jacking technology, applied in the field of lifting rescue, can solve the problems of drilling under the car, single lifting and resetting points, unsafe and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

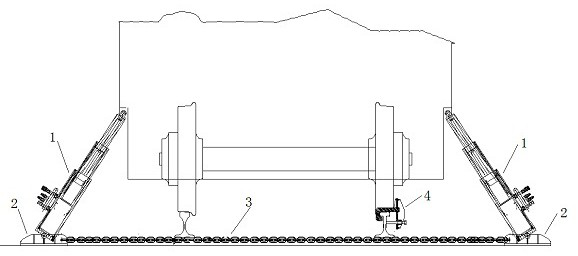

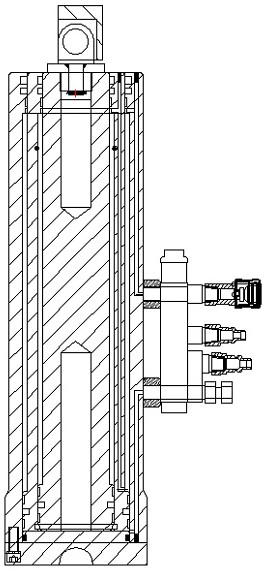

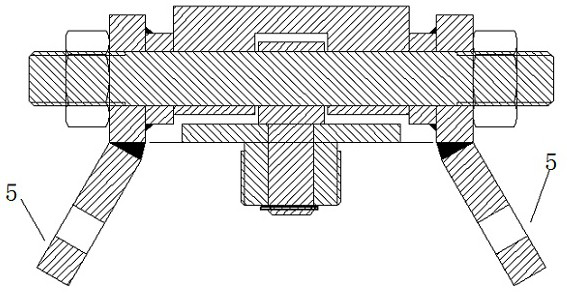

[0026] Such as figure 1 As shown, a lifting rescue method, the rerailing device used is as follows Figure 2-5 As shown, it includes the lifting oil cylinder 1 arranged on both sides of the derailed train, the upper part of the lifting oil cylinder 1 is equipped with an oil cylinder jacking, the middle position of the bottom of the lifting oil cylinder 1 is provided with a semicircular groove, the upper surface of the jacking is smooth, and the two sides of the jacking are flat. One hanging ear 5 is arranged on each side. The base 2 includes a bottom steel plate. A baffle plate with a semicircular groove 7 in the middle is welded on both sides of the steel plate. The size of the groove 7 is consistent with the size of the bottom groove of the lifting cylinder 1. The first lifting lug is installed on the baffle plate of the base through the round hole 6, the connecting rope 3 is connected to the two bases 2 through the lifting lug, the two bases 2 are connected with the connec...

Embodiment 2

[0030] Such as Figure 6 As shown, a lift-type rescue method, the rerailing device includes a lift cylinder 1, a base 2, a jacking support, a hydraulic pump station, a traverse beam 10, a traverse trolley 11, a rotary table 12 and pads. The specific implementation method is: under the off-line wheel bogie of the derailed train, a base 2 is placed between the rail and the roadbed, a lifting oil cylinder 1 is placed in the base, a jacking bracket is installed on the lifting oil cylinder, and the jacking is fixed on the car body frame For the parking space, use oil pipes to connect the hydraulic pump station with the lifting cylinder 1 and the traversing trolley 11 respectively, turn on the hydraulic pump station, lift the lifting cylinder 1 to lift the car body, place the traversing beam 10 under the bogie in turn, Install the traversing trolley 11 on the moving beam 10, place the rotary platform 12 on the traversing trolley 11, place an adjusting block with a suitable thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com