Automated storage system

A warehousing system and cargo technology, applied in the field of automated warehousing systems, can solve the problems of low utilization of storage space, low automation level, chaotic management, etc., and achieve the effect of avoiding outgoing errors and improving outgoing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

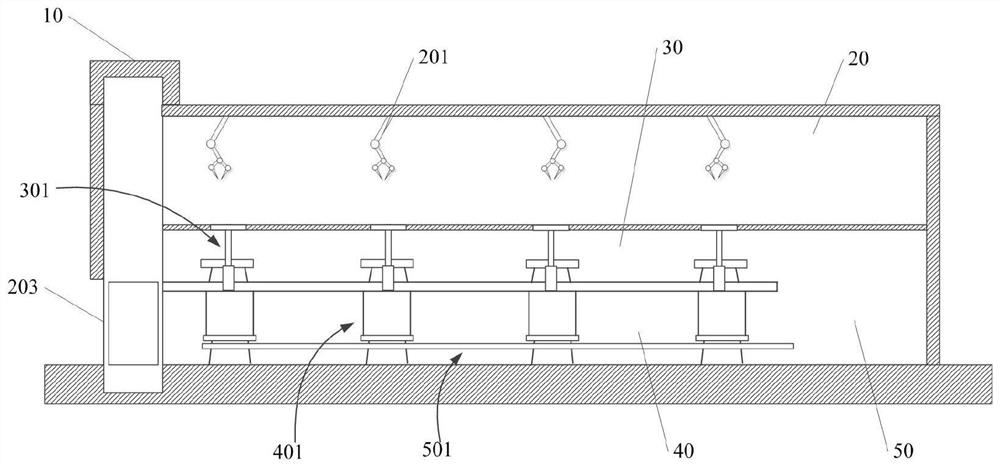

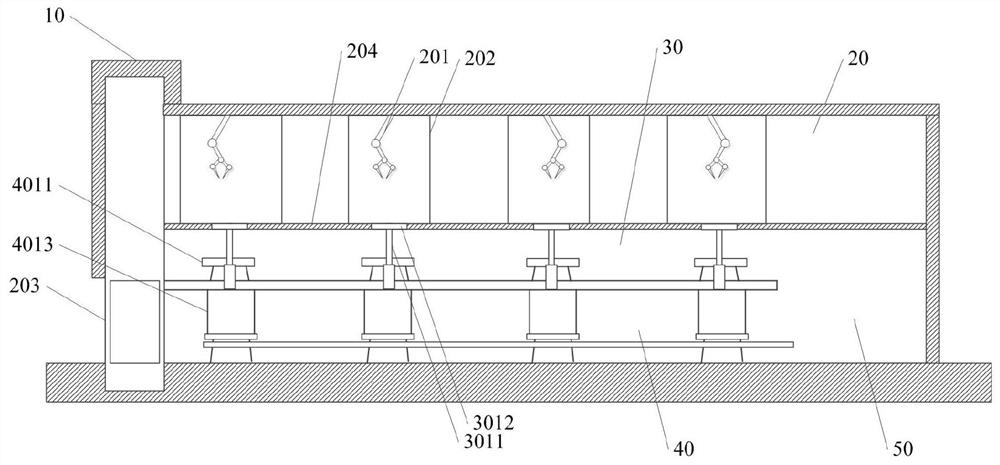

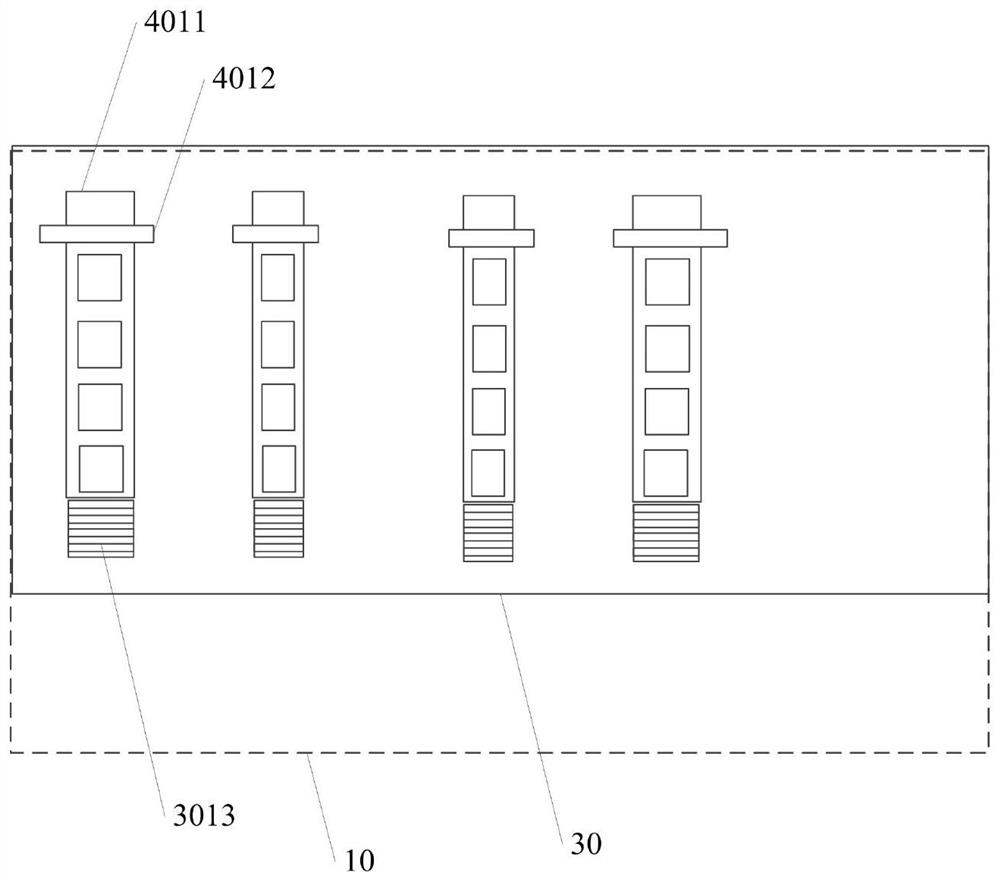

[0037] Such as figure 1 As shown, an automated storage system includes: a storage body 10, which includes a cargo storage area 20 connected from top to bottom, a cargo waiting area 30, a cargo sorting area 40, and a warehouse list verification area 50; a plurality of mechanical The arm 201 is slidably arranged on the ceiling of the cargo storage area; the upper ends of multiple mechanical arms realize sliding picking in the designated area through the structure of the sliding rail and the slider; the pressure-sensitive lifting component 301 is able to lift through Set in the goods storage area and the goods waiting area; the piece counting transmission component 401, which is set in the goods sorting area; the summary transmission component 501, which is set in the ware...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com