A spinning winding machine

A spinning and winding machine technology, which is used in the production of filaments, textiles and papermaking, and conveying filamentous materials, etc., can solve the problems of slow winding efficiency and achieve the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

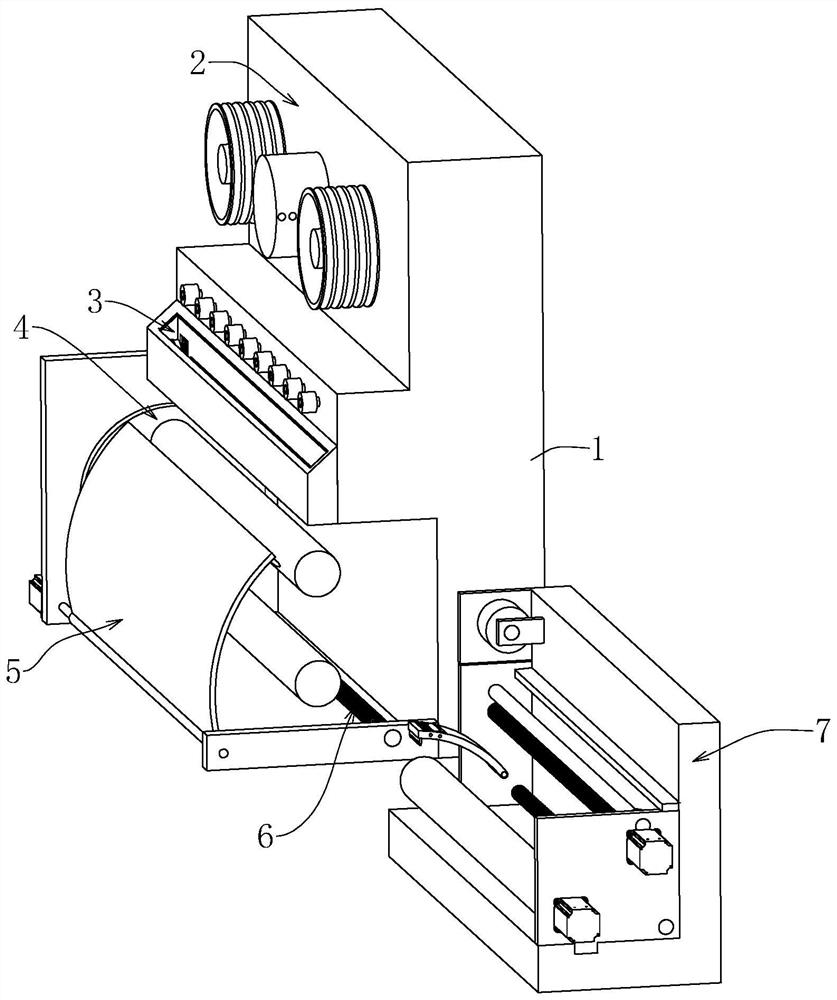

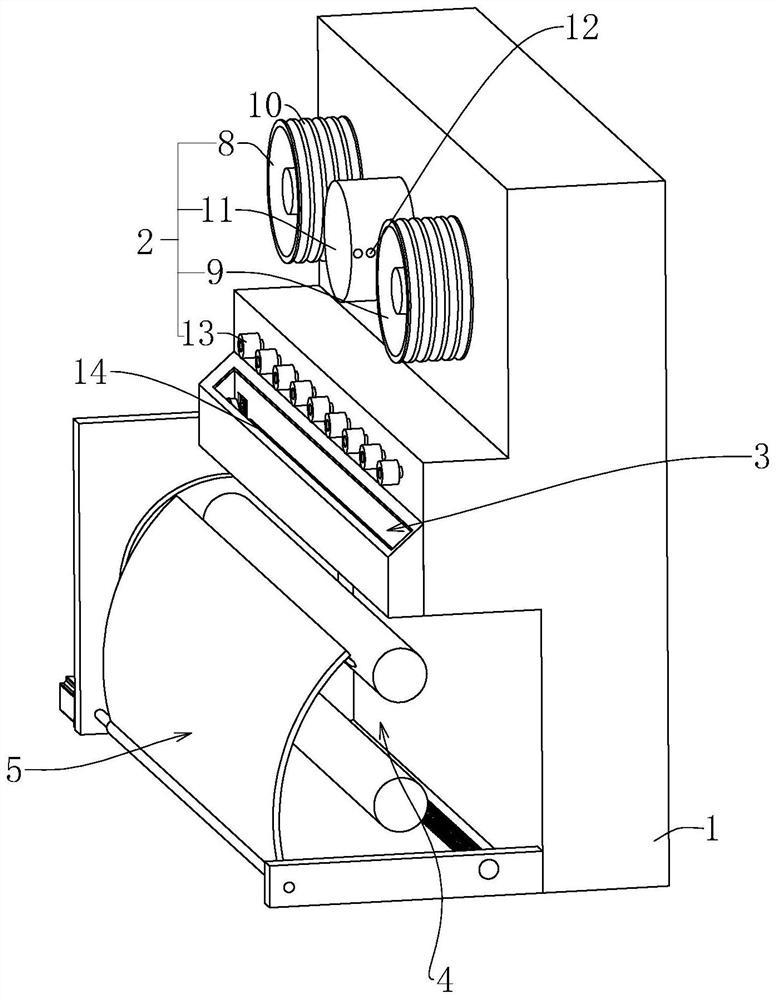

[0039] The embodiment of the present application discloses a spinning winding machine. refer to figure 1 , The spinning winding machine includes a support 1, on which a carding mechanism 2, a cycloid mechanism 3, an automatic winding mechanism 4, a cutting mechanism 5 and a pushing mechanism 6 are sequentially arranged along the yarn transport direction. An automatic gluing mechanism 7 is provided on the side of the support 1 .

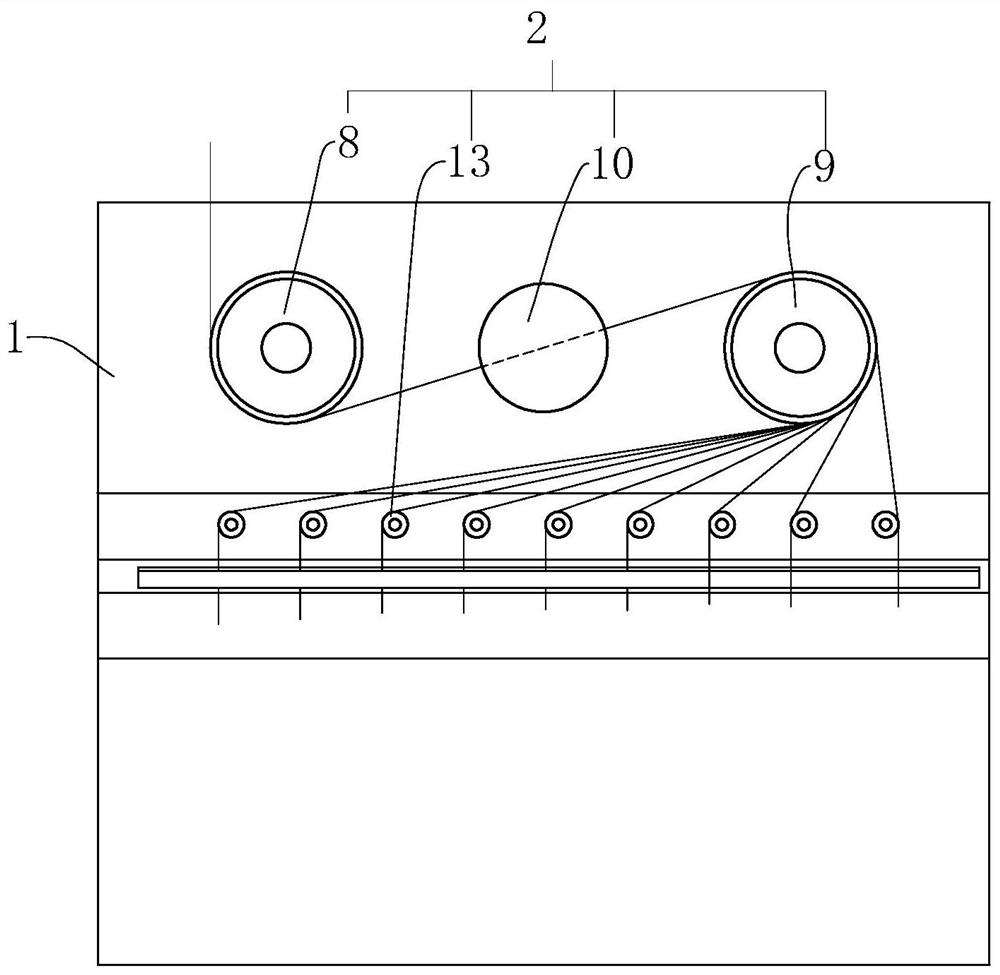

[0040] refer to figure 1 and figure 2, The carding mechanism 2 includes a main carding roller 8 and a secondary carding roller 9 that are rotatably connected to the top of the support 1 . Both the main opening roller 8 and the secondary opening roller 9 are provided with several opening slots 10 for yarns to pass through. A carding block 11 is fixed on the support 1 between the main carding roller 8 and the secondary carding roller 9 . The carding block 11 is provided with a plurality of through grooves for the yarn to pass through, and the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com