Clearing device and method for fine ores on conveyor belt

A technology for cleaning devices and conveyor belts, which is applied to cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as occupational hazards for operators, increase the labor intensity of manual cleaning for operators, and mine dust affects civilization and health. The effect of reducing occupational hazards, reducing labor intensity and improving working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

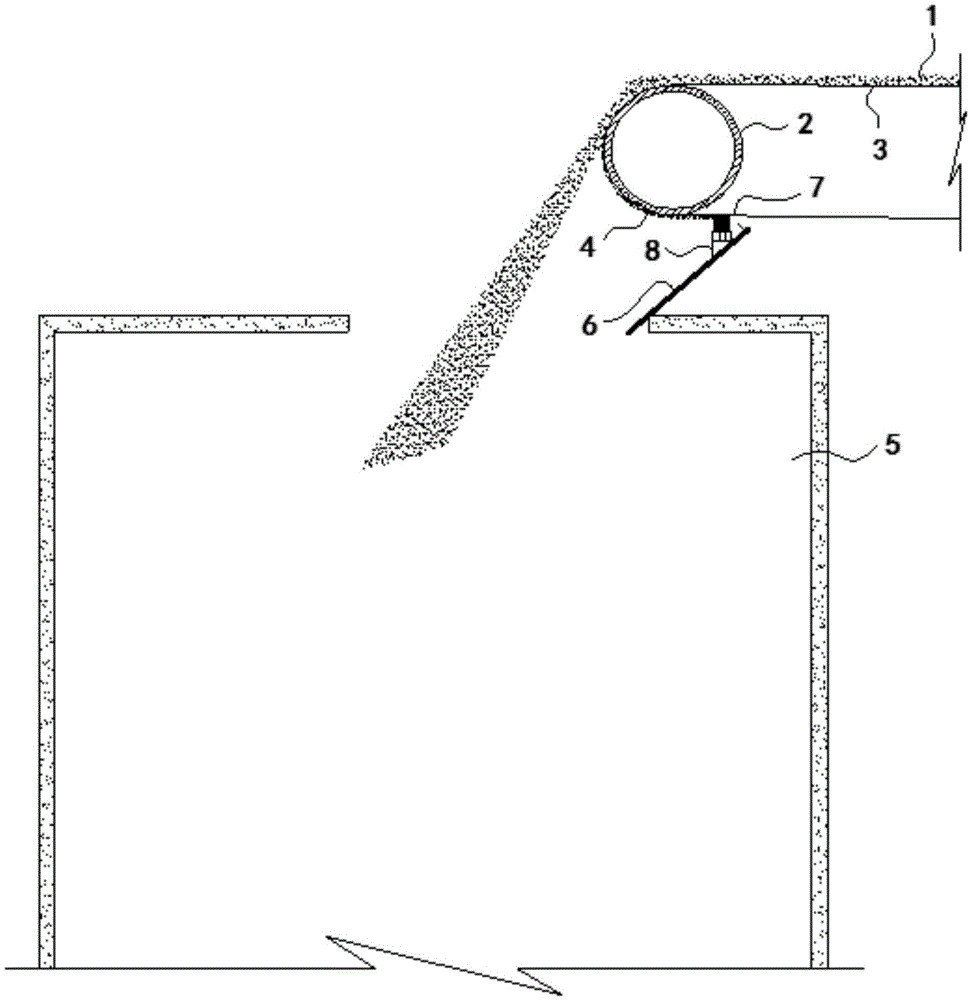

[0032] Such as figure 1 As shown, the cleaning device for fine ore attached to the conveyor belt according to the present invention includes: a belt feeder drum 2 (belt drive) of a belt 3, a brush 7, a brush seat and an adjustment device 8.

[0033] In one embodiment, the length of the brush 7 may be the same as the width of the belt 2, the width of the bristles of the brush 7 is 40-60mm, and the thickness of the brush is 40-50mm. A hairbrush 7 is fixedly installed on the chute 6, and the belt 2 with the fine ore 1 is in the rotation process, and the brush 7 brushes off the fine ore 1 stuck on the belt 2, so that the fine ore 1 falls into the chute 6. Enter the ore bin 5 through the ore chute 6, and automatically clean up the fine ore 1 stuck on the belt 2.

[0034] The device according to the invention has simple structure, practicality, low input cost, convenient installation, no power device, and basically no operating cost. In various embodiments, the length of the hairb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com