a smoke processor

A processor and smoke technology, applied in chemical instruments and methods, dispersed particle filtration, transportation and packaging, etc., can solve problems that affect product welding performance and production line progress, achieve ingenious structure, high market value, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

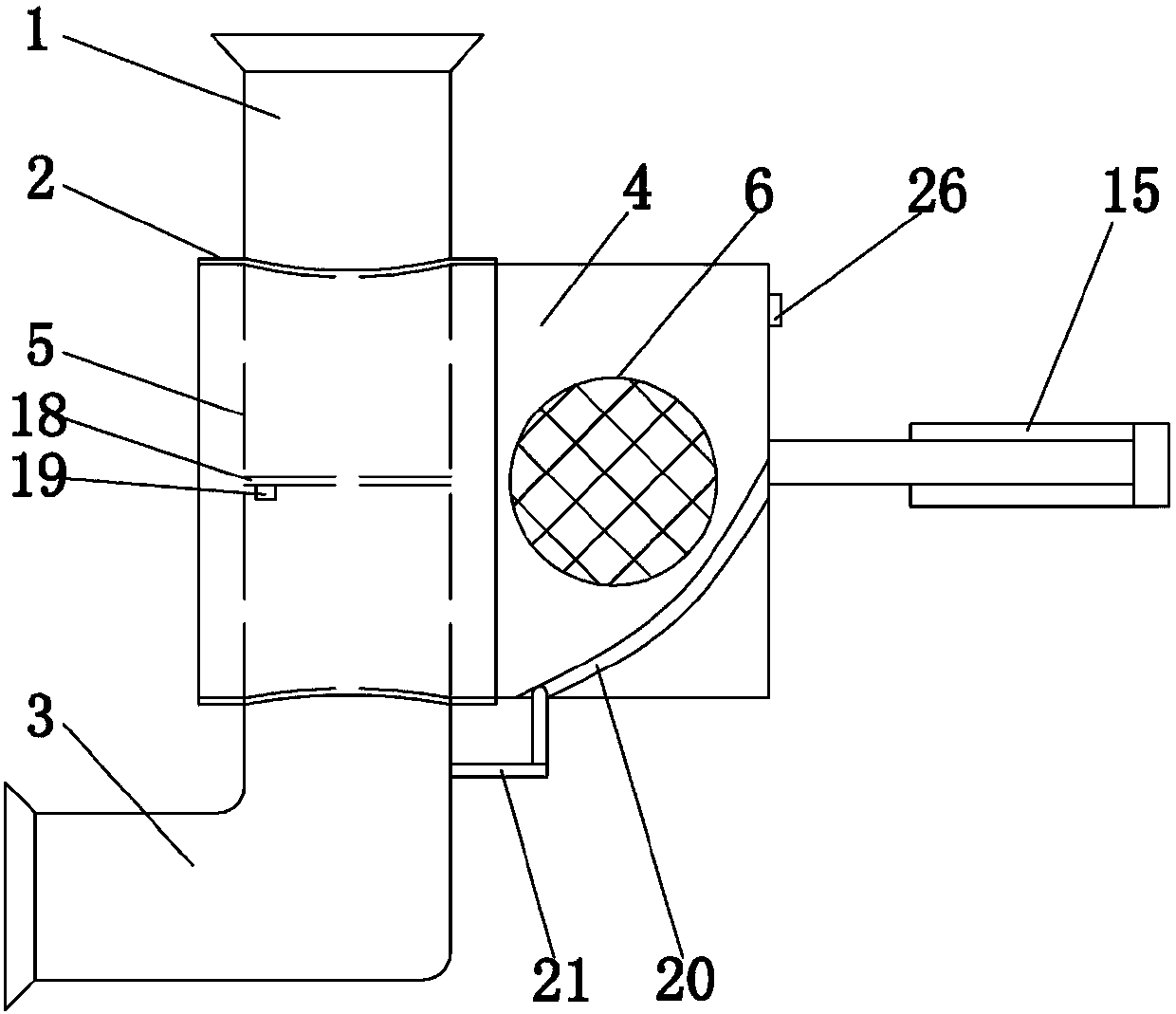

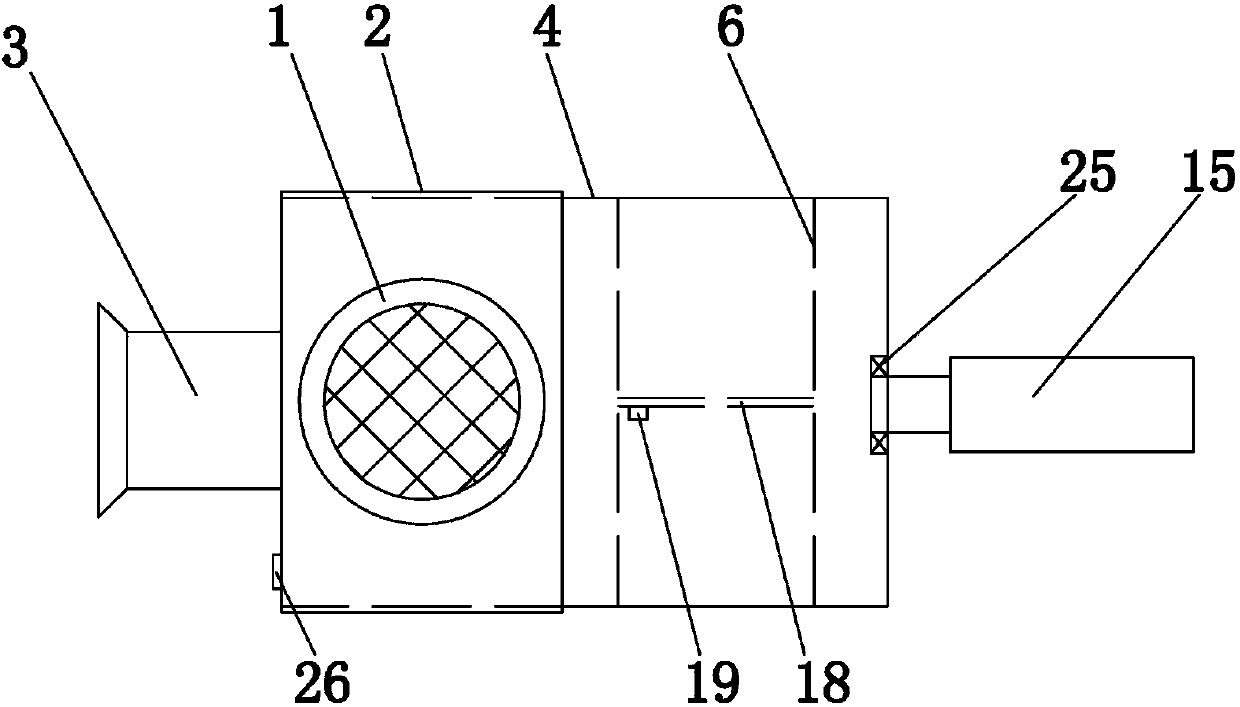

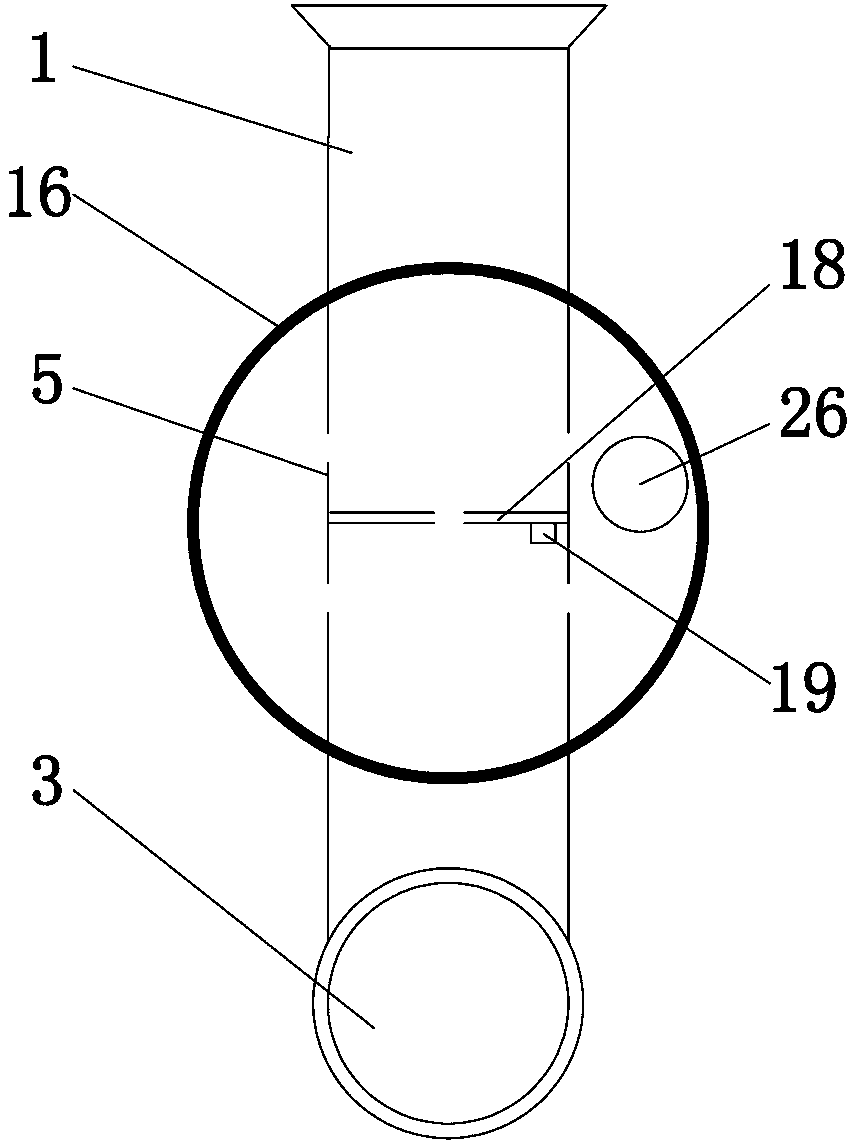

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Depend on Figure 1 to Figure 9 Given, a smoke processor, including an air intake pipe 1, a horizontal sleeve 2 is fixed at the lower end of the air intake pipe 1, an outlet pipe 3 is fixed at the lower end of the horizontal sleeve 2, and a cylinder 4 is slidably connected inside the horizontal sleeve 2, Sealed connection between the cylinder 4 and the transverse casing 2;

[0020] The cylinder 4 is provided with mutually perpendicular and non-intersecting left through holes 5 and right through holes 6, the cylinder 4 includes a base 7 and an upper end cover, the base 7 includes a left column and a right column, and the left column The body is provided with a left plane 9, and the right cylinder is provided with a right plane 10 perpendicular to the left plane 9. The axis of the cylinder 4 passes through the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com