Cable cabling device and method of use thereof

A cable and cabling technology, which is applied in the directions of transportation and packaging, thin material handling, and filamentary material transportation, can solve the problems of a small number of windings, the cable winding is not tight, and the smooth operation of the cabling is affected, and the operation is achieved. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

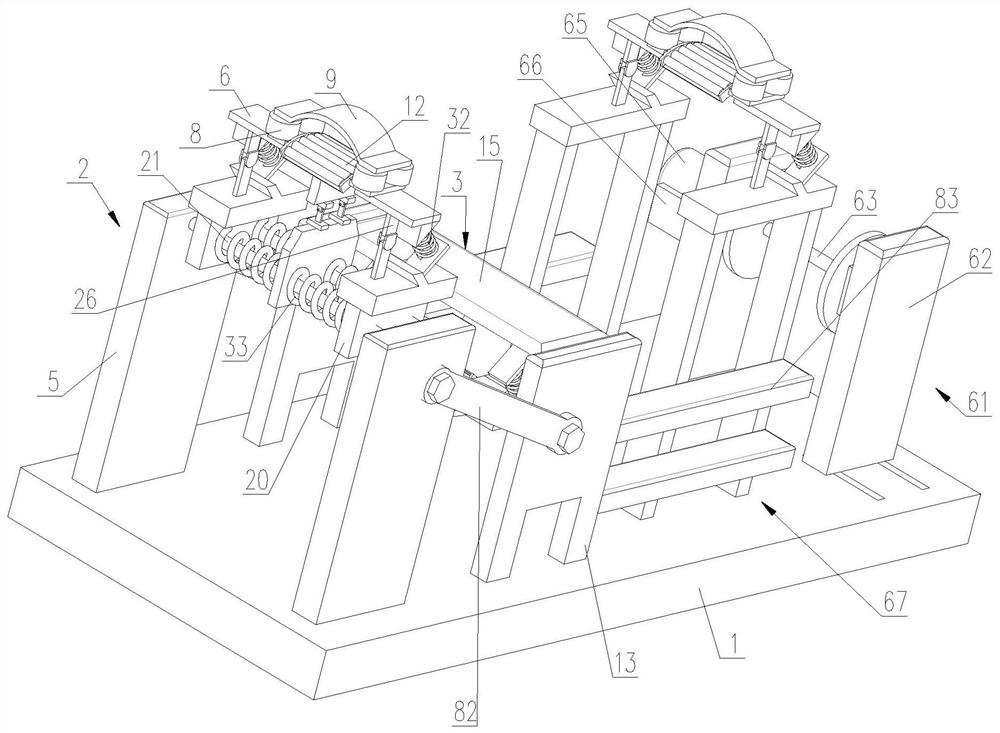

[0033] like Figure 1 to Figure 6 As shown, a cable cabling device includes a base 1 on which a first tensioning unit 2 and a depressing unit 3 are arranged;

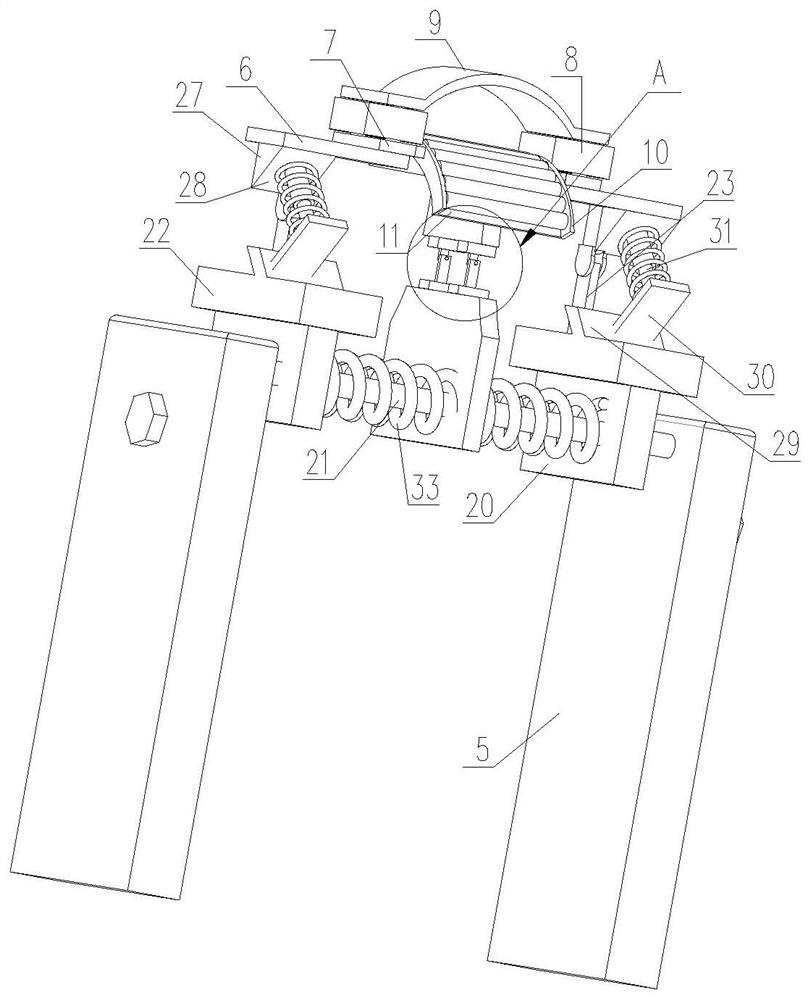

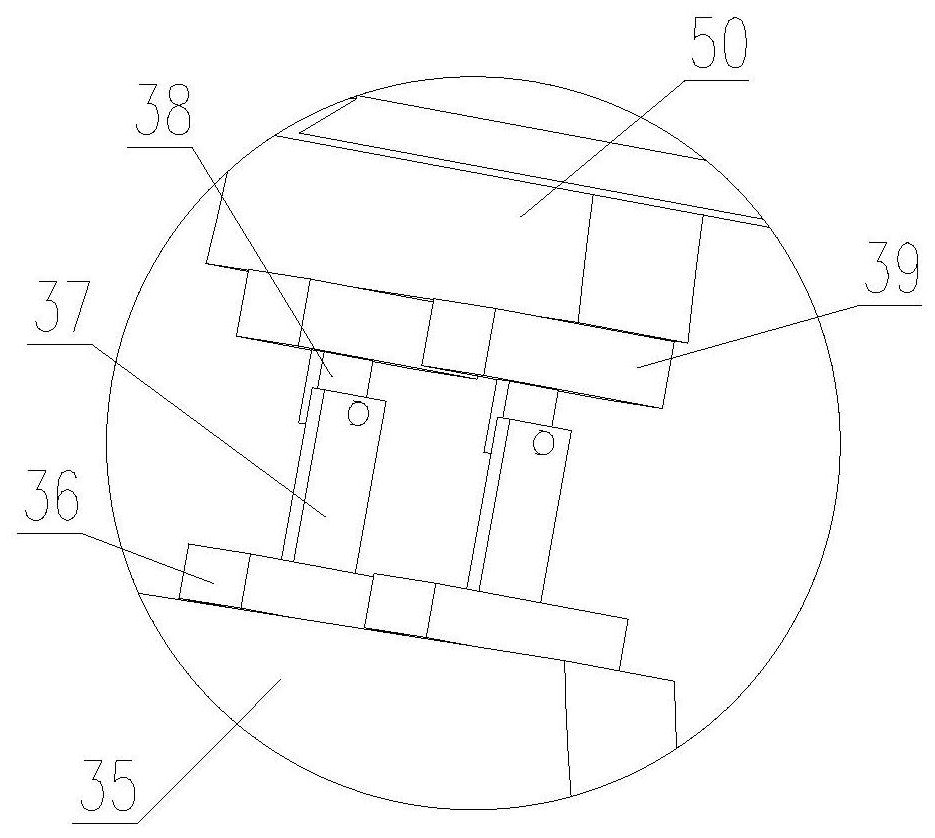

[0034] The first tensioning unit 2 includes two first positioning plates 5 arranged symmetrically to each other, two first connecting blocks 6 are arranged between each of the first positioning plates 5, and each of the first connecting blocks 6 The upper end is provided with an extension block 7, and each of the extension blocks 7 is provided with two first rotating rods, and each of the first rotating rods is provided with a first sleeve 8, and the two adjacent first rotating rods The sleeves 8 are arranged at intervals, and the upper ends of each of the first rotating rods are respectively connected to the two ends of the first arc-shaped plate 9; a second arc-shaped plate 10 is arranged between ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com