Wire spool device for optical fiber manufacturing and capable of avoiding disordered winding

A winding reel and chaotic technology, which is applied in the field of winding reel devices for optical fiber manufacturing, can solve the problems of imperfect structure of the winding reel, unreasonable control of the winding speed, and affecting the quality of the winding, so as to avoid damage to the wire after drawing Optical fiber, easy to adjust the effect of winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

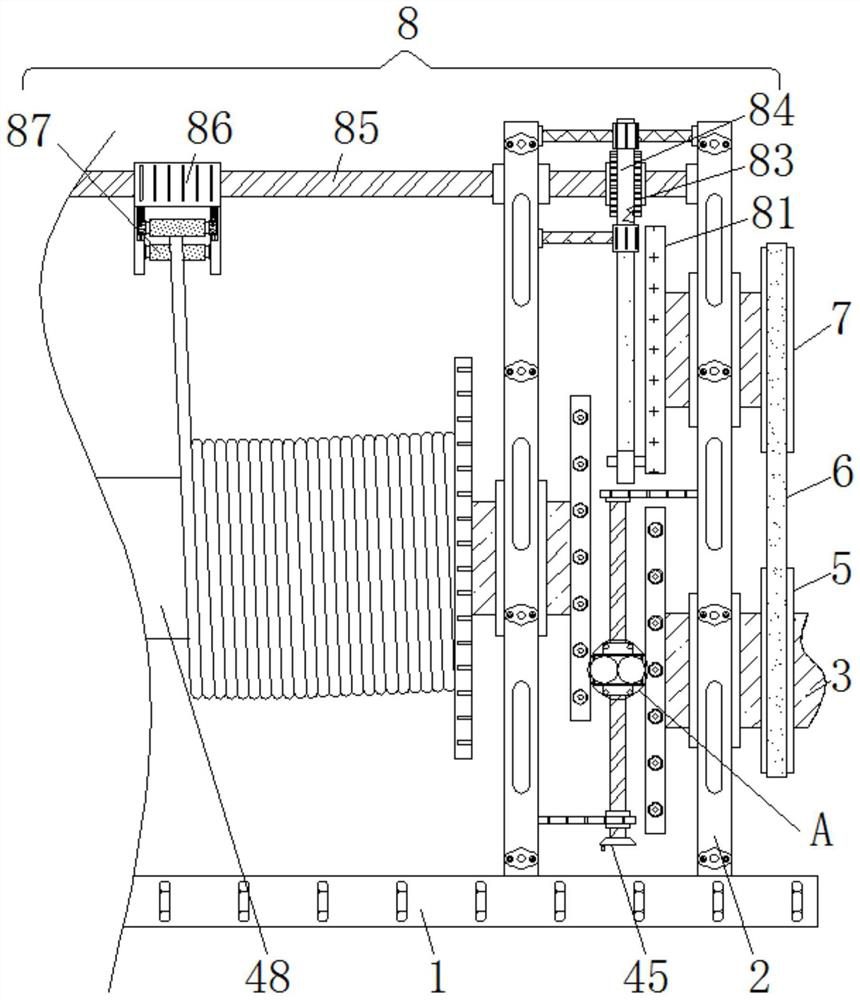

[0029] A winding reel device for optical fiber manufacturing that avoids winding confusion, including a base 1, the top of the base 1 is fixedly connected with a fixed plate 2, the inside of the fixed plate 2 is movably connected with a drive shaft 3, and the right side of the drive shaft 3 is fixedly connected There is a drive motor, which is not specifically shown in the figure. The left side of the drive shaft 3 is fixedly connected with a speed regulating mechanism 4, the outer wall of the drive shaft 3 is fixedly connected with a drive disc 5, and the bottom of the drive disc 5 is connected with a belt 6. A driven disc 7 is connected to the side away from the drive disc 5. The shape and size of the driven disc 7 are the same as that of the drive disc 5, and the driven disc 7 is directly above the drive disc 5, and the left side of the driven disc 7 is fixed. A guide mechanism 8 is connected.

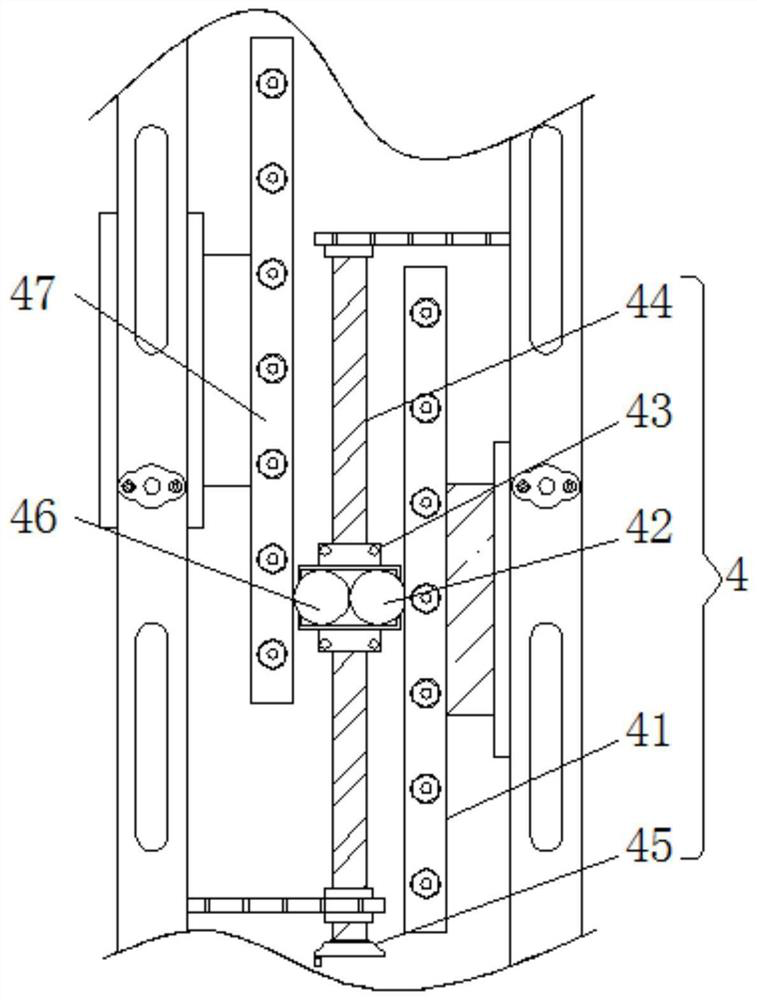

[0030] The inside of the speed regulating mechanism 4 is provided with a first ...

Embodiment 2

[0032] A winding reel device for optical fiber manufacturing that avoids winding confusion, including a base 1, the top of the base 1 is fixedly connected with a fixed plate 2, the inside of the fixed plate 2 is movably connected with a drive shaft 3, and the right side of the drive shaft 3 is fixedly connected There is a drive motor, which is not specifically shown in the figure. The left side of the drive shaft 3 is fixedly connected with a speed regulating mechanism 4, the outer wall of the drive shaft 3 is fixedly connected with a drive disc 5, and the bottom of the drive disc 5 is connected with a belt 6. A driven disc 7 is connected to the side away from the drive disc 5. The shape and size of the driven disc 7 are the same as that of the drive disc 5, and the driven disc 7 is directly above the drive disc 5, and the left side of the driven disc 7 is fixed. A guide mechanism 8 is connected.

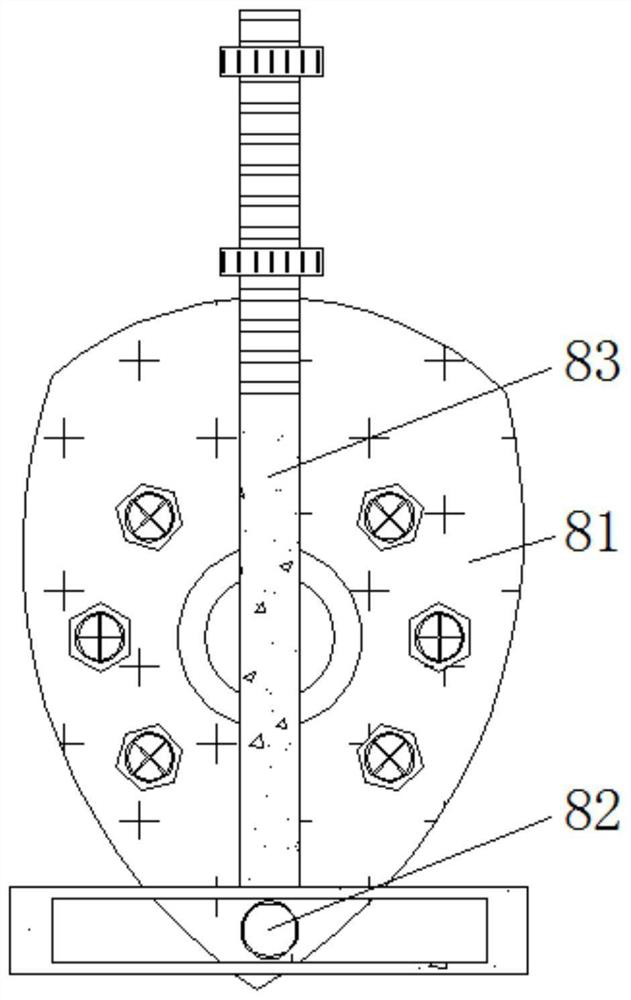

[0033] The inside of the guide mechanism 8 is provided with a cam 81, the right...

Embodiment 3

[0035] A winding reel device for optical fiber manufacturing that avoids winding confusion, including a base 1, the top of the base 1 is fixedly connected with a fixed plate 2, the inside of the fixed plate 2 is movably connected with a drive shaft 3, and the right side of the drive shaft 3 is fixedly connected There is a drive motor, which is not specifically shown in the figure. The left side of the drive shaft 3 is fixedly connected with a speed regulating mechanism 4, the outer wall of the drive shaft 3 is fixedly connected with a drive disc 5, and the bottom of the drive disc 5 is connected with a belt 6. A driven disc 7 is connected to the side away from the drive disc 5. The shape and size of the driven disc 7 are the same as that of the drive disc 5, and the driven disc 7 is directly above the drive disc 5, and the left side of the driven disc 7 is fixed. A guide mechanism 8 is connected.

[0036]The inside of the speed regulating mechanism 4 is provided with a first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com