An iron core winding device for transformer production and processing

A winding device, transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of low work efficiency, time-consuming, poor work quality, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

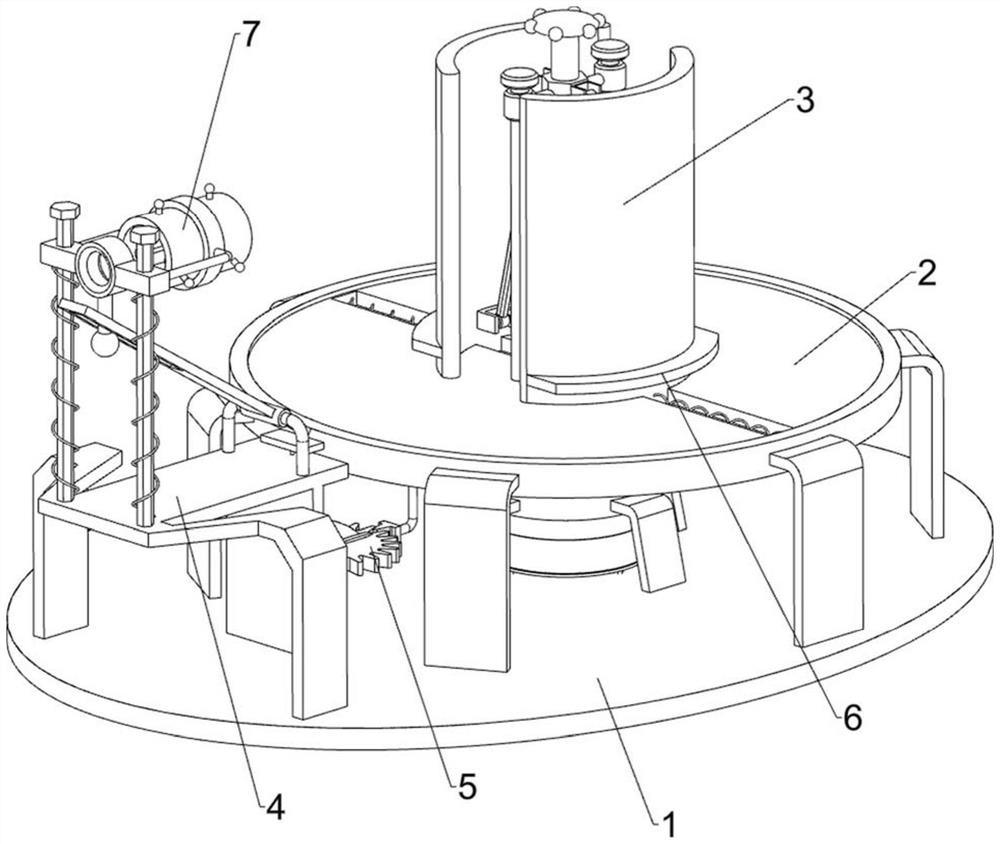

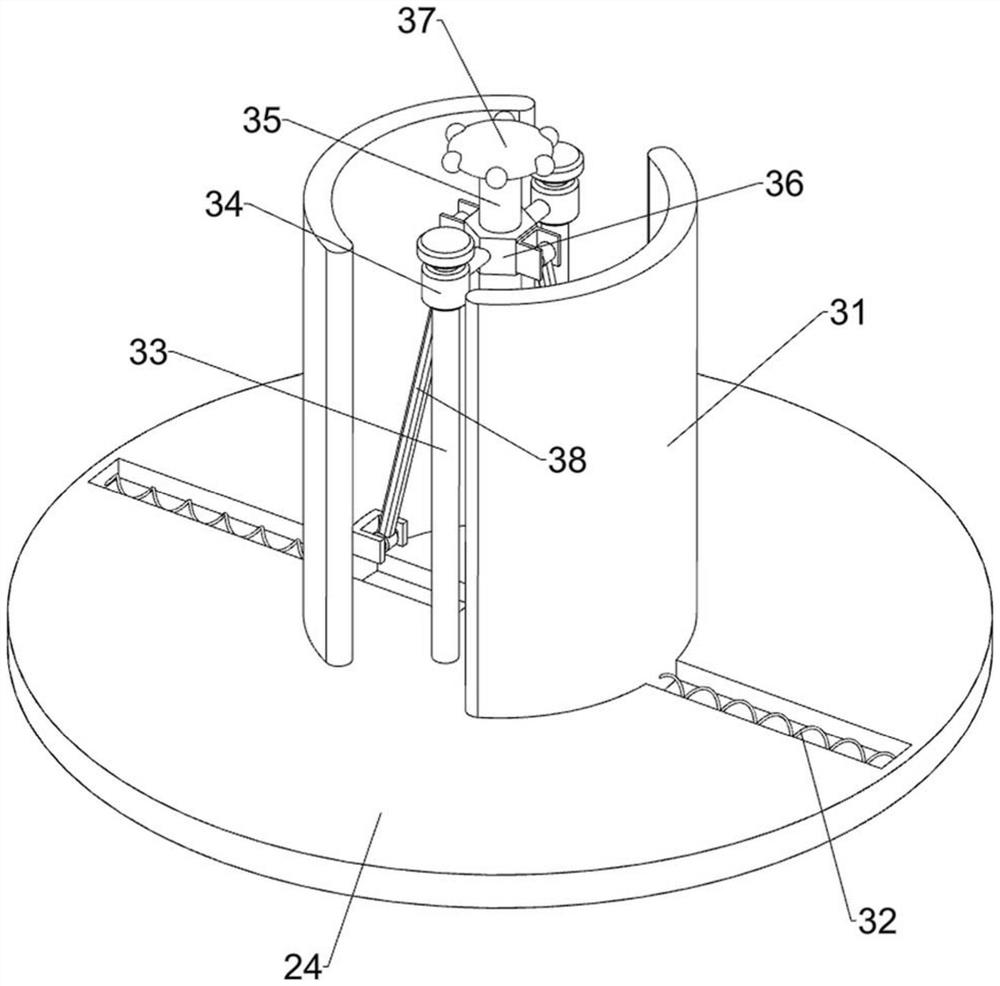

[0023] An iron core winding device for transformer production and processing, such as Figure 1-6 As shown, it includes a base 1 , a rotating assembly 2 and a fixed assembly 3 , the base 1 is provided with a rotating assembly 2 which rotates by rotation, and the rotating assembly 2 is provided with a fixed assembly 3 which is fixed by sliding.

[0024] When using the device, the staff puts the iron core on the fixed assembly 3, and after putting it away, winds one end of the copper wire around the iron core, and then, the staff starts the rotating assembly 2, and drives the fixed assembly 3 through the rotating assembly 2 Turn to wind the copper wire on the iron core. After the winding is completed, the staff closes the rotating assembly 2.

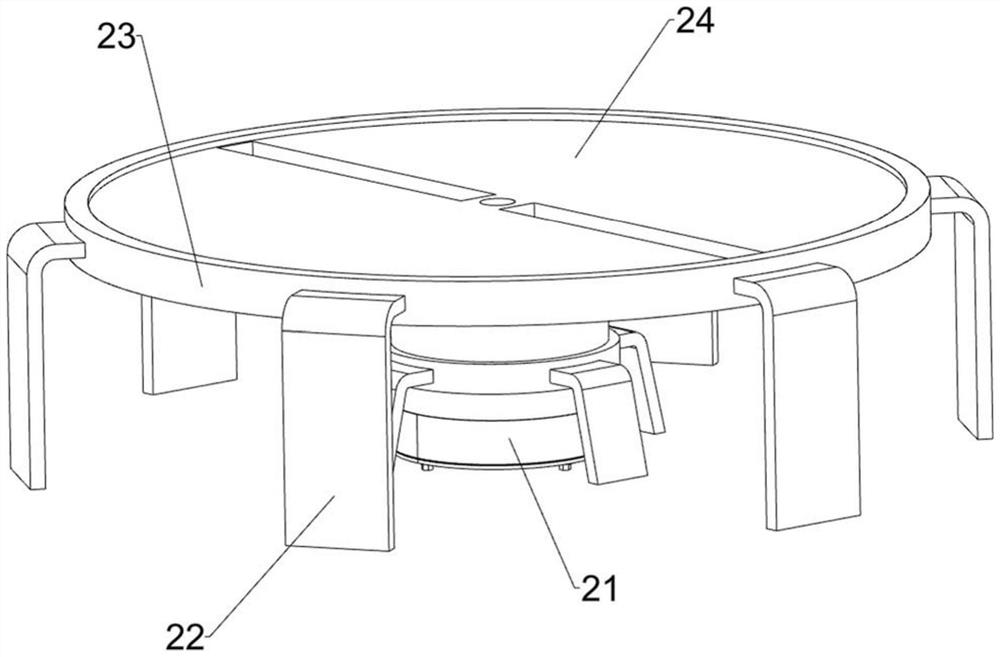

[0025] Such as figure 1 , figure 2 , image 3 with Figure 5 As shown, the rotating assembly 2 includes a geared motor 21, a mounting block 22, an annular guide rail 23 and a turntable 24, the base 1 is fixedly connected with a geare...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , Figure 4 with Figure 5 As shown, a lead assembly 4 is also included, and the lead assembly 4 includes a special-shaped frame 41, a prismatic guide rod 42, a second spring 43, a first slider 44 and a wire ring 45, and the left part of the base 1 is provided with a special-shaped frame 41, The left part of the special-shaped frame 41 is provided with two prismatic guide rods 42, and the first slide block 44 is all slidably provided on the prismatic guide rod 42, and the first slide block 44 and the prismatic guide rod 42 are all wound with the first slide block. Two springs 43 , and a wire loop 45 is arranged between the two first sliders 44 .

[0031] When winding the iron core, the worker passes one end of the copper wire through the wire ring 45 and winds it on the iron core. While winding, the worker pushes the first slider 44 to slide on the prismatic guide rod 42, The second spring 43 is compressed and reset thereup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com