A rotor copper wire winding device for a rotating electrical machine

A technology for rotating electrical machines and rotor copper, used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of poor copper wire winding effect, uneven copper wire winding, and a lot of dust on copper wire, etc. Quality and efficiency, achieve the effect of winding, improve the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

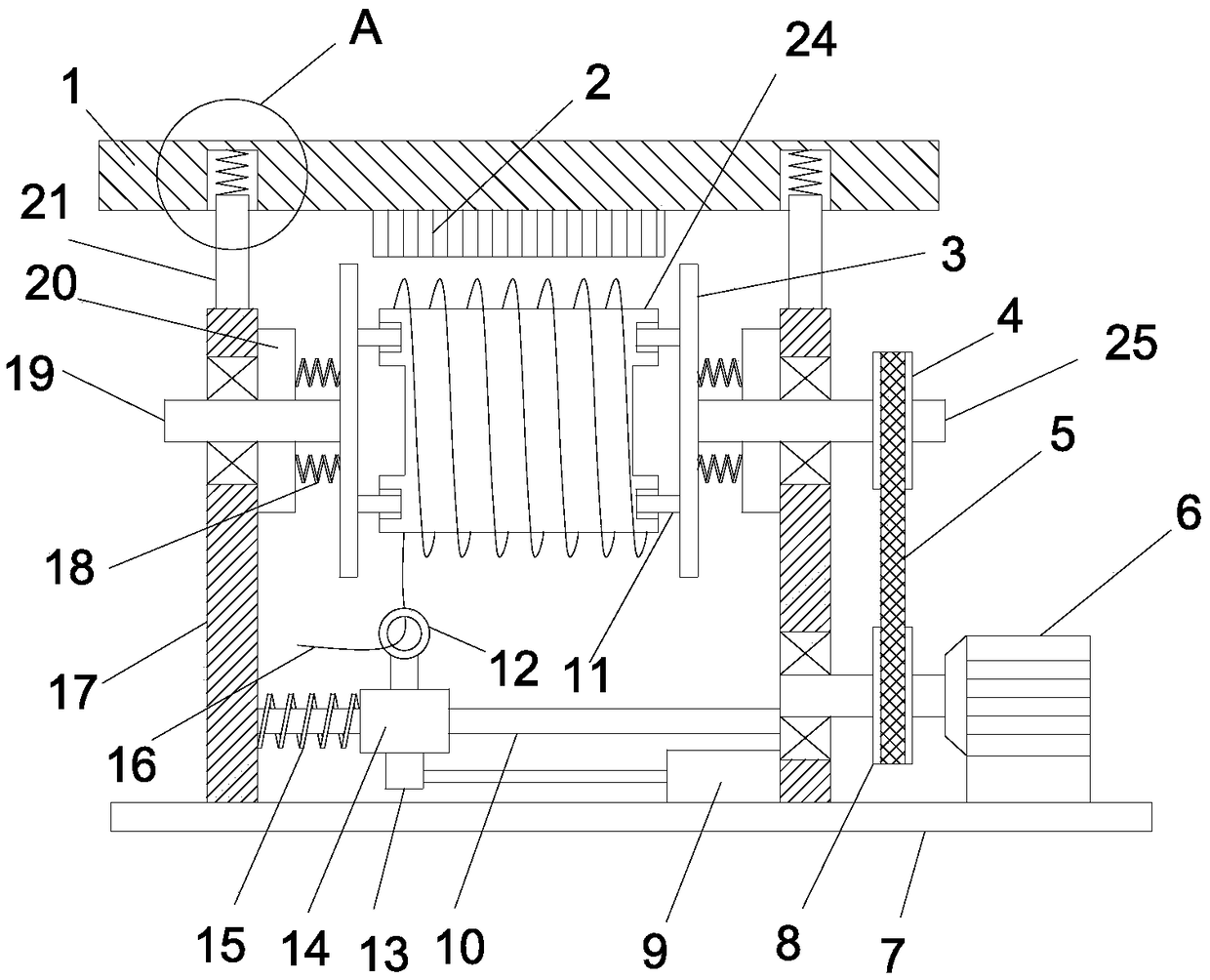

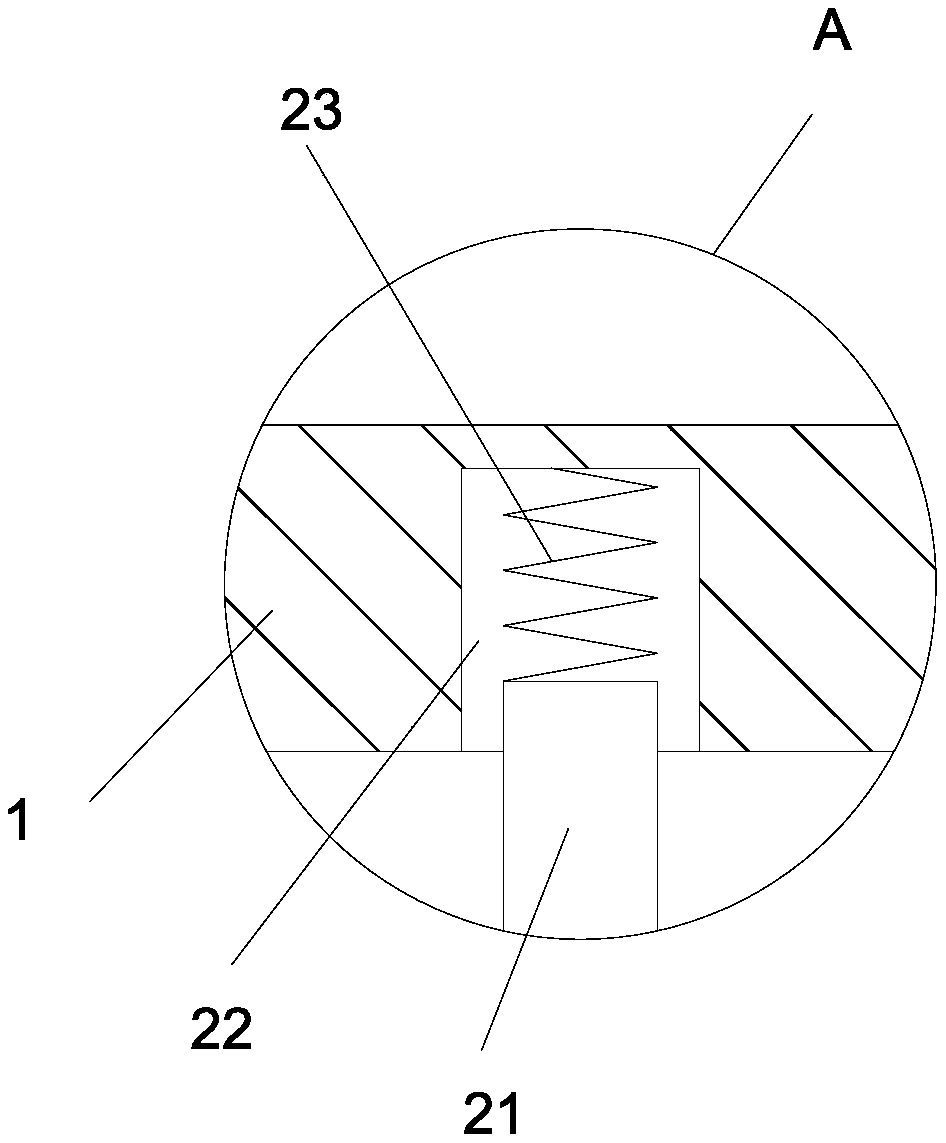

[0017] see Figure 1-2 , a rotor copper wire winding device for a rotating electrical machine, comprising a base plate 7, two vertical plates 17 are welded and fixed on the base plate 7, and the two vertical plates 17 are evenly perpendicular to the base plate 7; each of the vertical plates On the plate 17, a buffer shaft 21 is vertically fixedly installed, a top plate 1 is arranged above the vertical plate 17, and a dust removal brush 2 is provided on the bottom surface of the top plate 1; The buffer shaft 21 is slidably embedded in the limit chute 22, the second limit spring 23 is arranged in the limit chute 22, the upper end of the second limit spring 23 is fixed on the top plate 1, and the second limit spring The lower end of 23 is fixed on the buffer shaft 21; the first connecting shaft 19 and the second connecting shaft 25 are respectively horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com