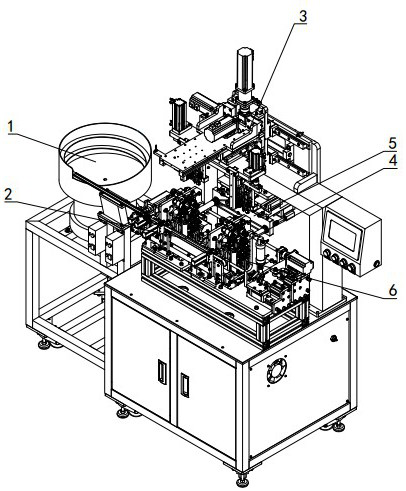

Full-automatic winding machine

A fully automatic winding machine and winding technology, applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of low winding efficiency, waste of enameled wire, large enameled wire margin, etc., and achieve winding The effect of high speed and low waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

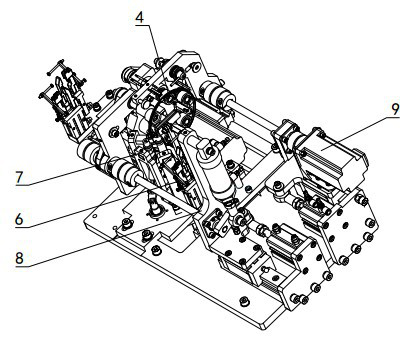

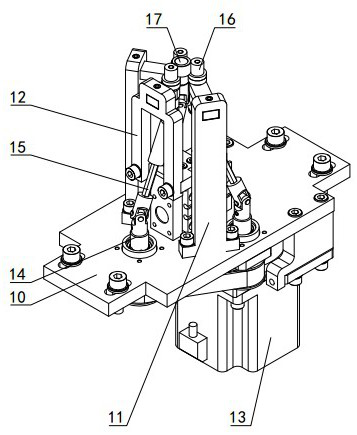

[0030] Figure 1~13 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~13 The present invention will be further described.

[0031] A fully automatic winding machine, comprising a winding device 4, a magnetic ring rotating device 7 and a wire storage ring support device 8, the winding device 4 is provided with a storage ring 39, and also includes a manipulator 3, a wire clamping device 6 and The wire twisting device 9, the wire storage ring 39 is arranged between the wire winding device 4 and the wire clamping device 6, the manipulator 3 is provided with a winding clamping part and a winding guide sleeve 3803, the winding clamping part and the winding guide sleeve 3803 are arranged at intervals, the thread twisting device 9 is provided with a thread twisting part, and the thread storage ring 39 is provided with a thread hanging groove 3902 matched with the thread twisting part, and the thread twisting device 9 is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com