Concrete crack picture splicing and detecting method

A detection method and concrete technology, applied in the field of detection and stitching of concrete crack pictures, can solve the problems of single picture, failure to achieve large-scale crack picture stitching, integration of detection, and inability to obtain the complete shape and relative position of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will now be further described in conjunction with the embodiments and drawings:

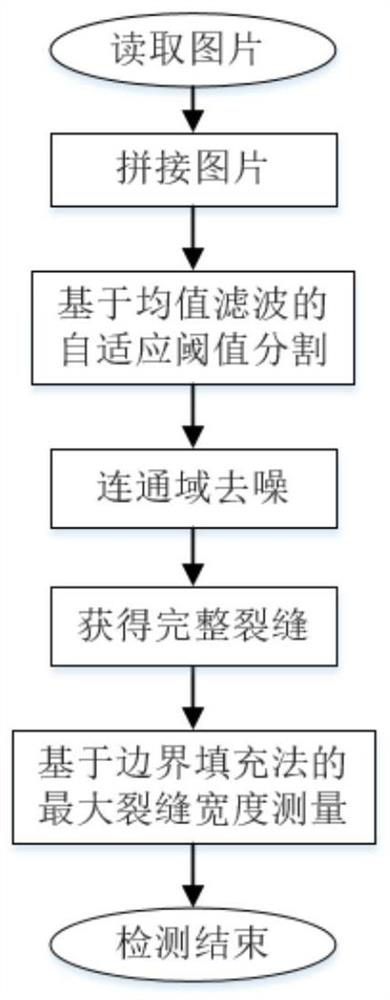

[0052] The method for splicing and detecting crack pictures provided by the embodiment of the present invention, the flowchart is as follows figure 1 As shown, the method specifically includes the following steps:

[0053] (1) Mosaic pictures;

[0054] (2) Adaptive threshold segmentation based on mean filtering;

[0055] (3) Denoising of connected domains;

[0056] (4) The maximum width measurement method based on boundary filling measures the maximum width and position of cracks.

[0057] The following is a detailed description of each step:

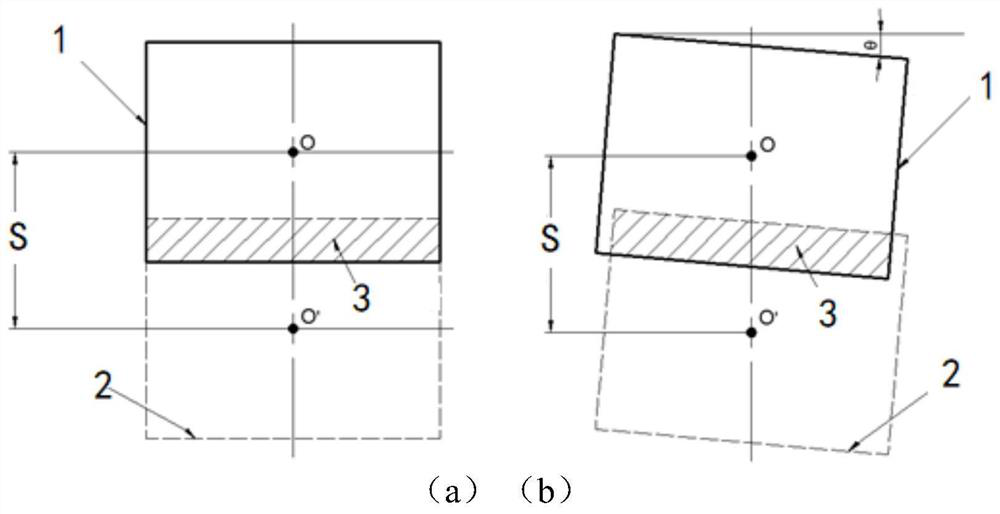

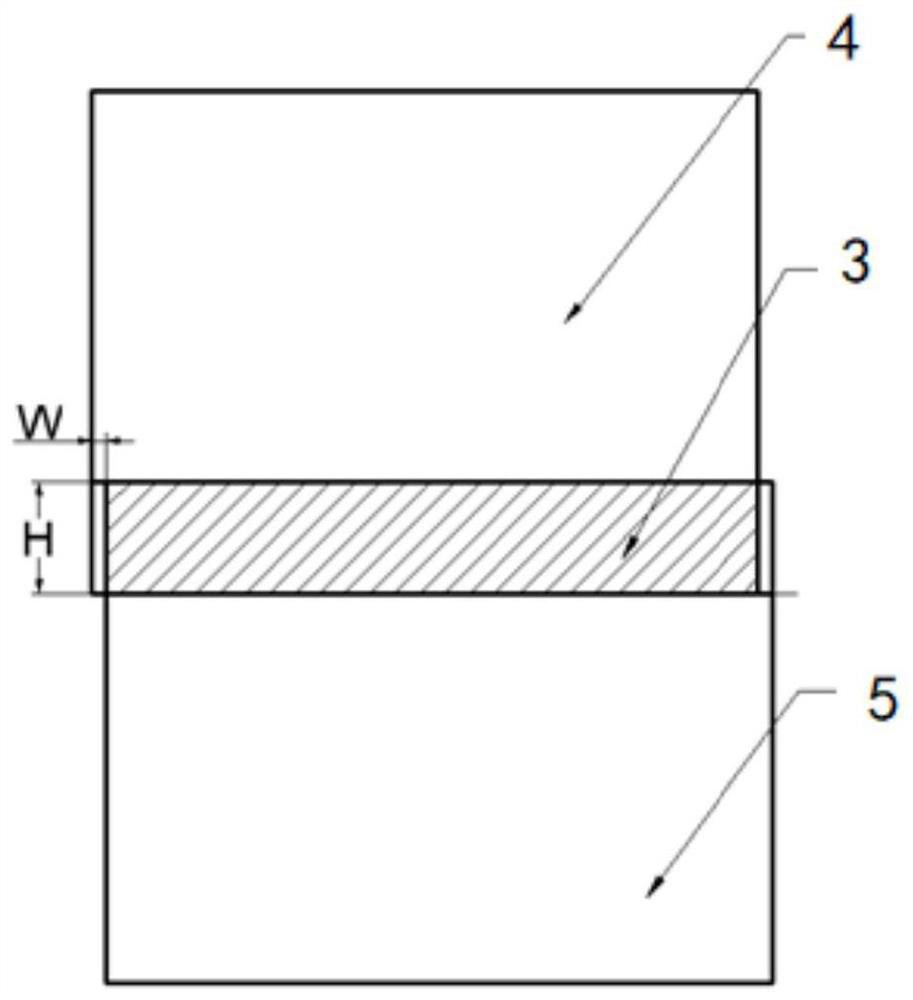

[0058] First of all, in order to facilitate the understanding of the embodiments of the present invention, a phenomenon in the camera shooting process is introduced here, such as figure 2 As shown, when the camera shoots a plane along a straight line (camera displacement S), in the ideal shooting state, see figure 2 (A), the width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com