Forming and detecting integrated 3D printing equipment

A 3D printing and equipment technology, applied in the field of metal additive manufacturing, can solve the problems of increasing production cost and production cycle, scrapping molded parts, and detecting molding defects in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will combine Figure 1 ~ Figure 3 The 3D printing equipment integrating forming and testing of the present invention will be further described in detail.

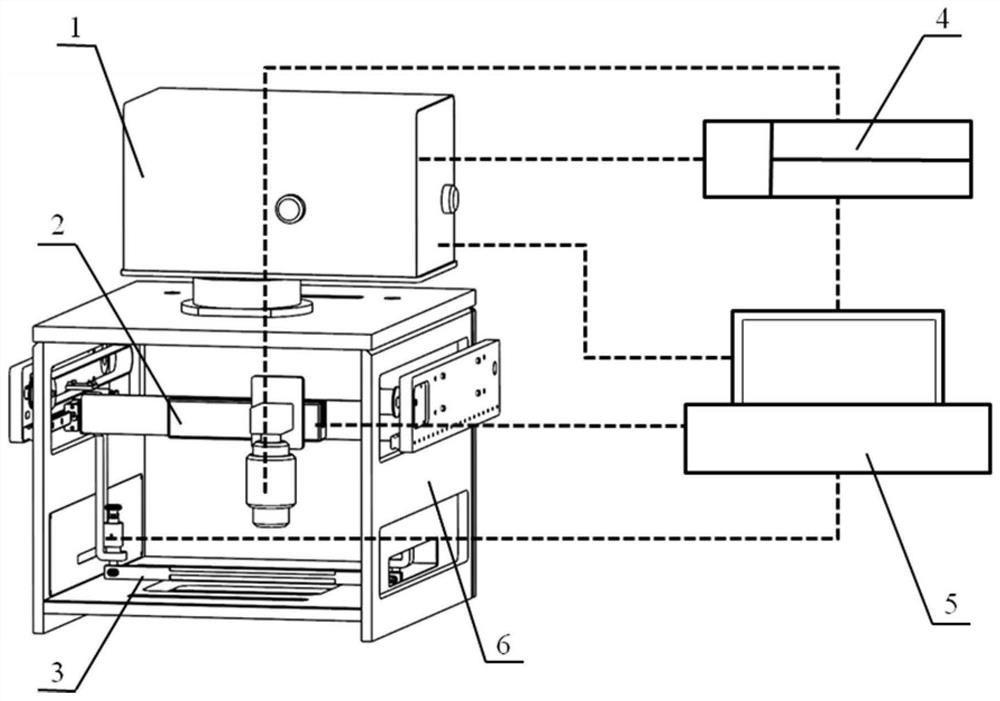

[0021] figure 1 Shown is a schematic structural diagram of a 3D printing device integrating forming and testing according to a preferred embodiment of the present invention.

[0022] see figure 1 , the 3D printing device integrating forming and testing in this embodiment includes a laser generator 4, an optical path system 1, a mobile laser detection and receiving system 2, an upper vacuum box 6, a scraper assembly 3 and an industrial computer 5;

[0023] The laser generator 4 is used to generate shaping laser, excitation laser and detection laser;

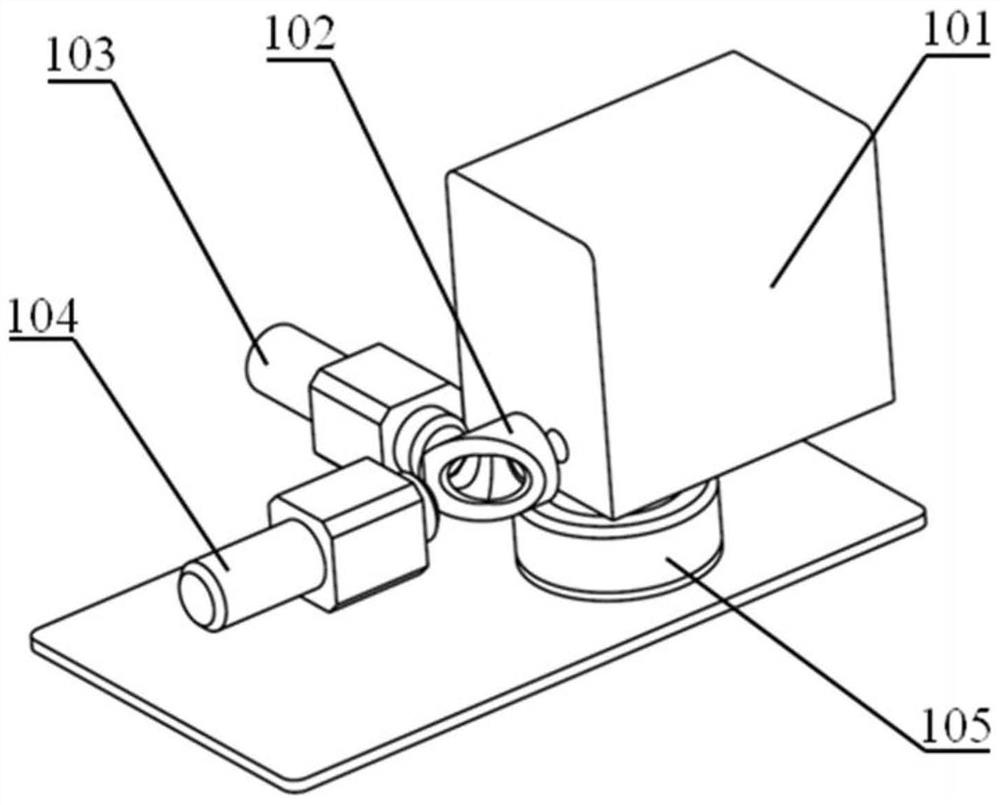

[0024] The optical path system 1 is arranged on the upper vacuum box 6;

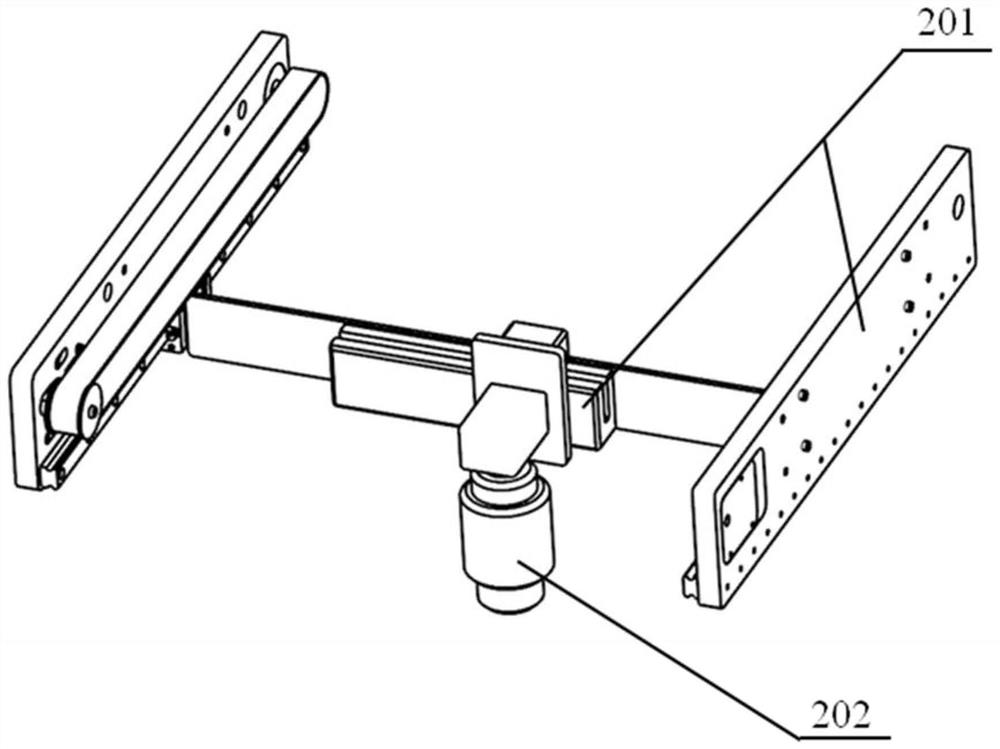

[0025] The mobile laser detection and receiving system 2 is installed in the upper vacuum box 6; the mobile laser detection and reception system 2 includes an XY stepping system a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap