Multi-ultrasonic-assisted method for enhancing the forming quality of cmt aluminum alloy additive manufacturing

An additive manufacturing and ultrasonic-assisted technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve problems such as large residual stress, large temperature gradient, and excessive deformation of formed parts, so as to improve mechanical properties and reduce residual Stress, the effect of improving the fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

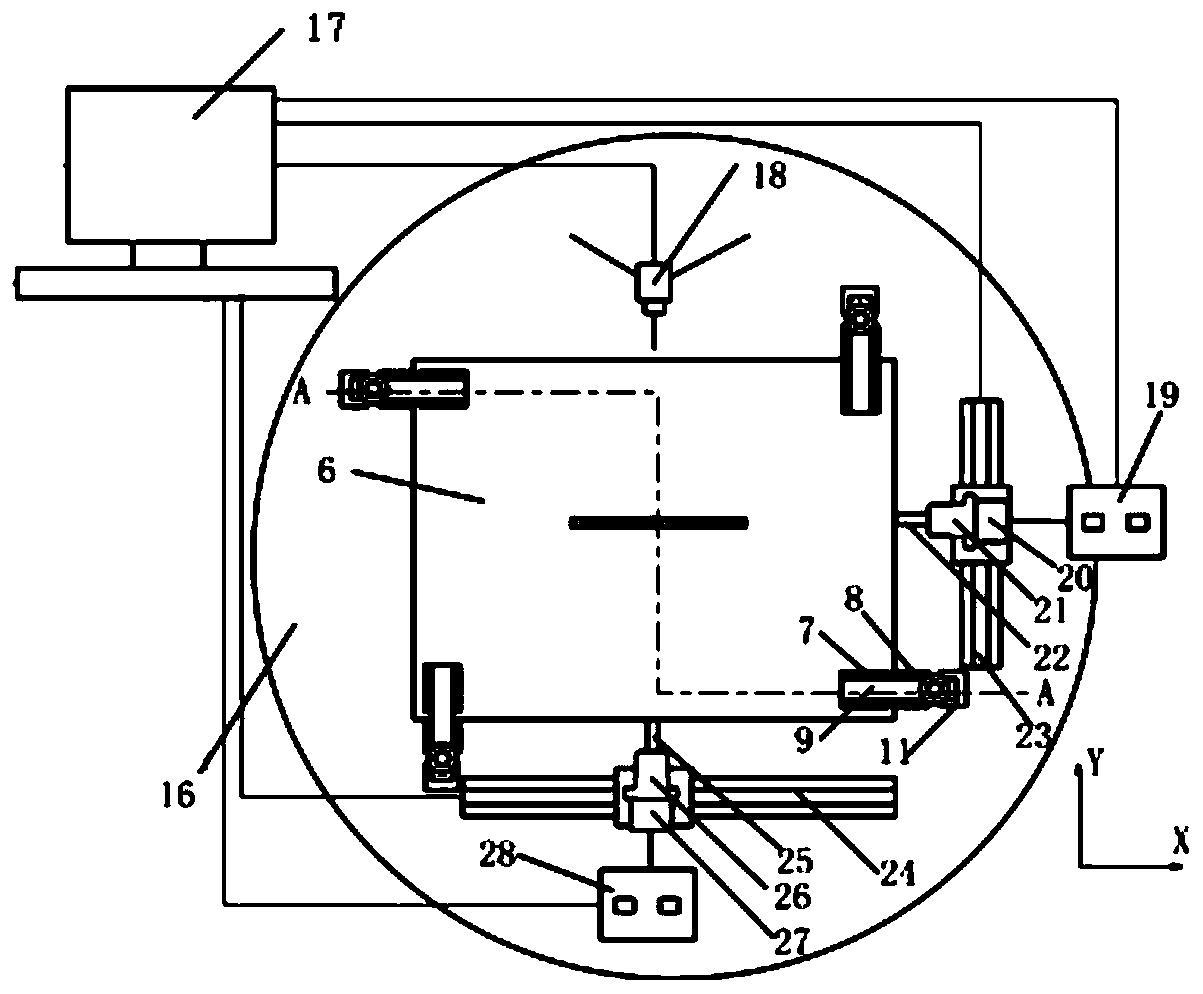

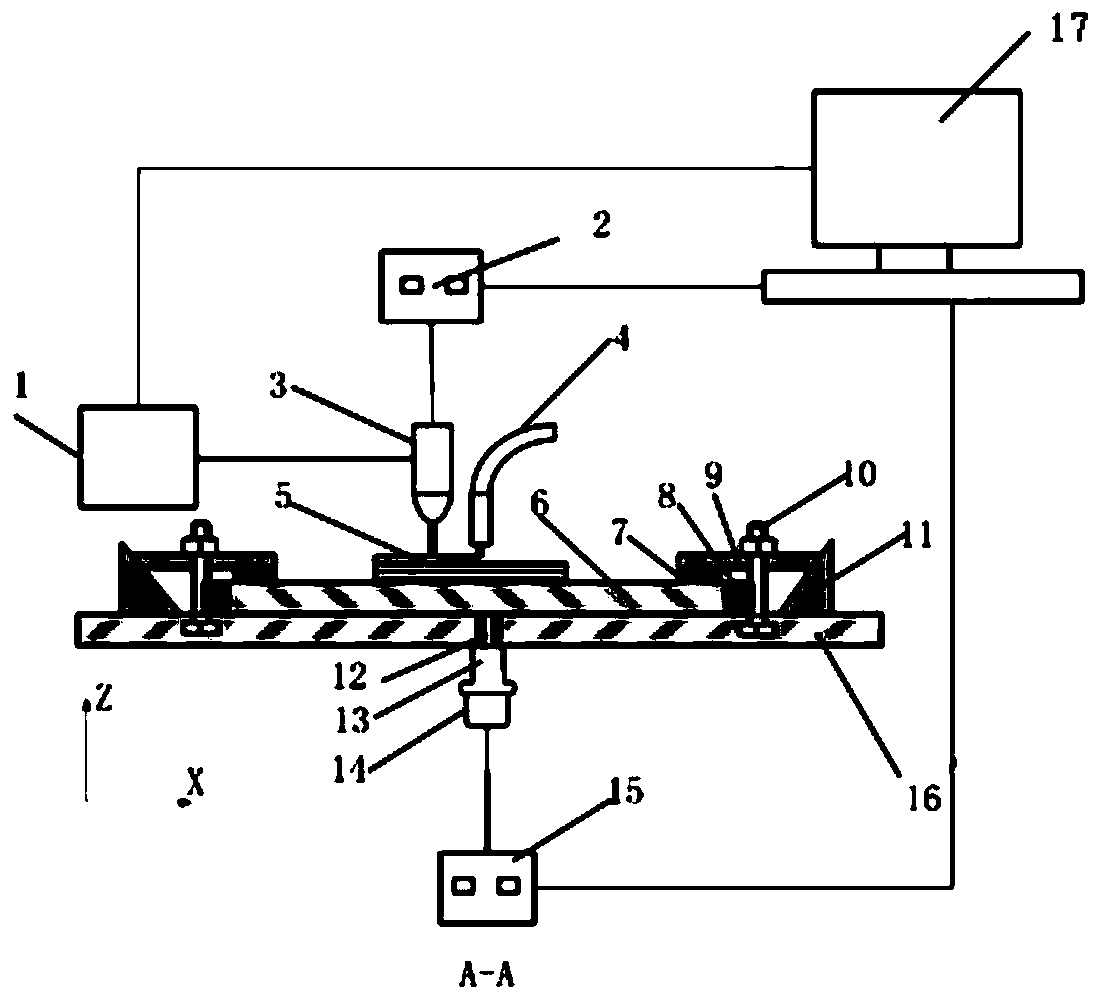

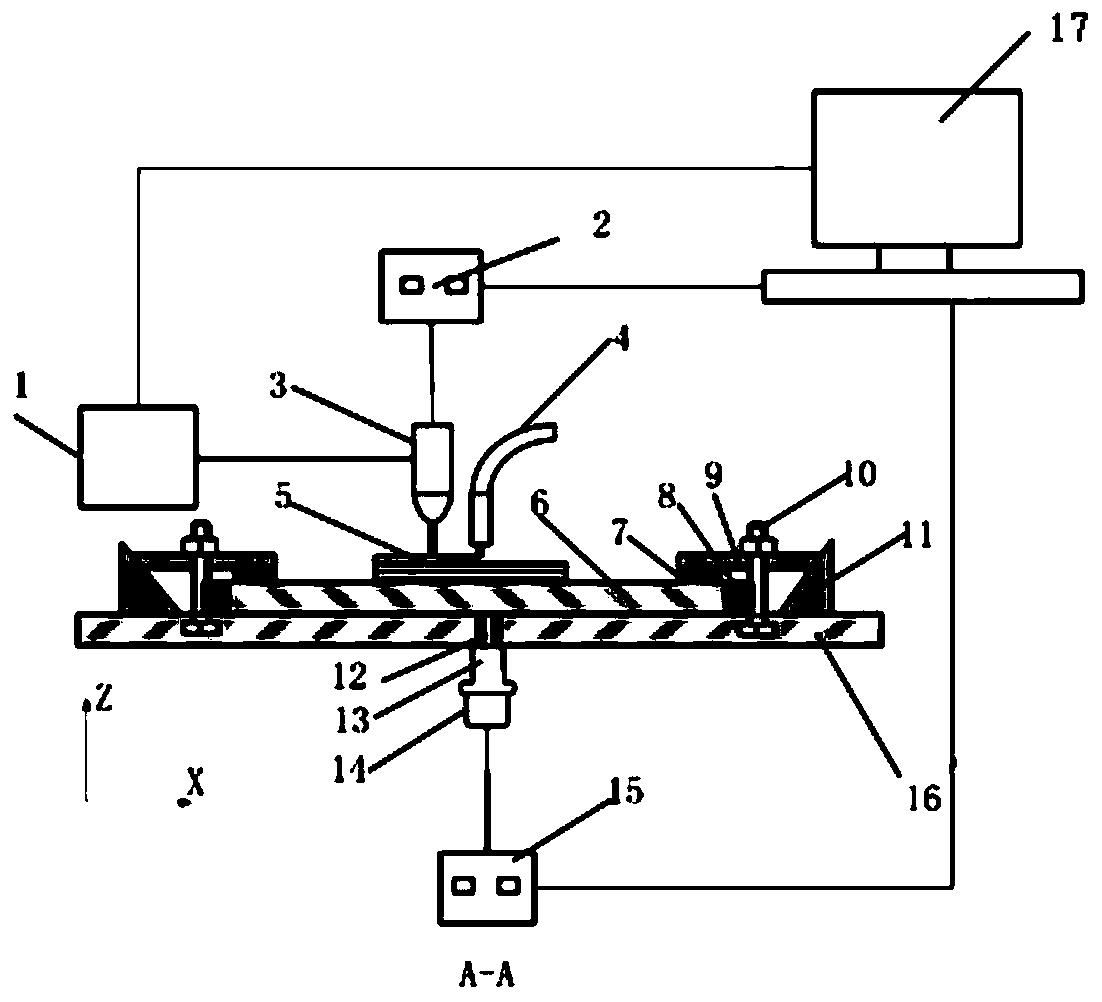

[0045] The purpose of the present invention is aimed at the difficulties in the forming process of CMT aluminum alloy additive manufacturing technology, and provides a device and method for multi-ultrasonic assisted enhancement of the forming quality of CMT aluminum alloy additive manufacturing; Introduce the coupling and stirring effect of high-frequency ultrasonic energy in three directions, and use the substrate fixing device to fix the substrate with hard rubber pads, so that the substrate generates small high-frequency vibrations while transmitting ultrasonic high-frequency energy waves, making the melting During the solidification process of the pool metal, it is subjected to the comprehensive action of high-frequency ultrasonic stirring in three directions and the micro-high-frequency v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com