Arc additive manufacturing method of controllable magnetic field assisted inclined members

An additive manufacturing and magnetic field-assisted technology, applied in the field of additive manufacturing, can solve problems such as difficulty in ensuring the forming quality, achieve the effects of overcoming the instability of stacked parts and edge collapse, reducing the amount of processing, and reducing the temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

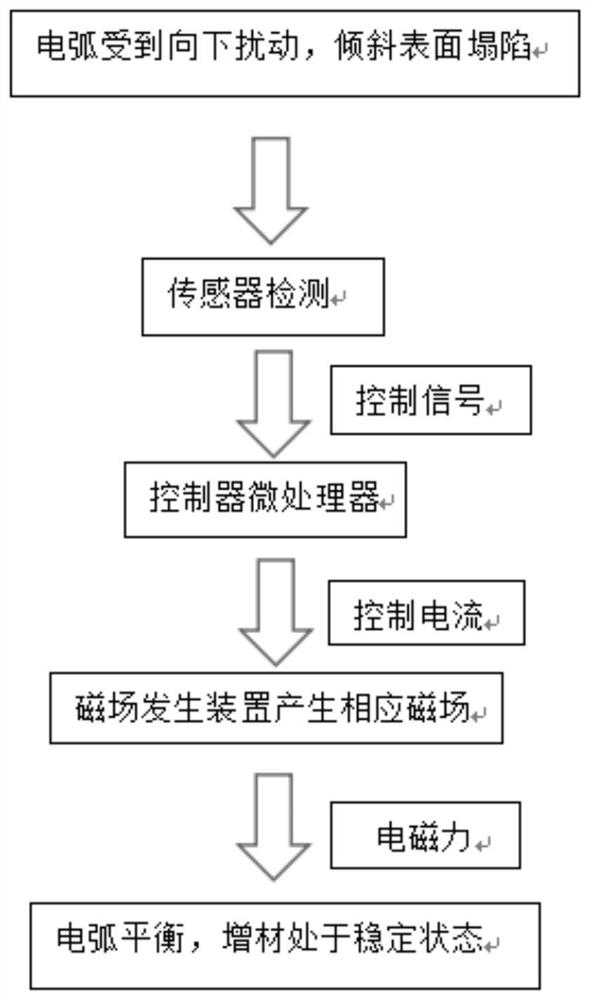

Problems solved by technology

Method used

Image

Examples

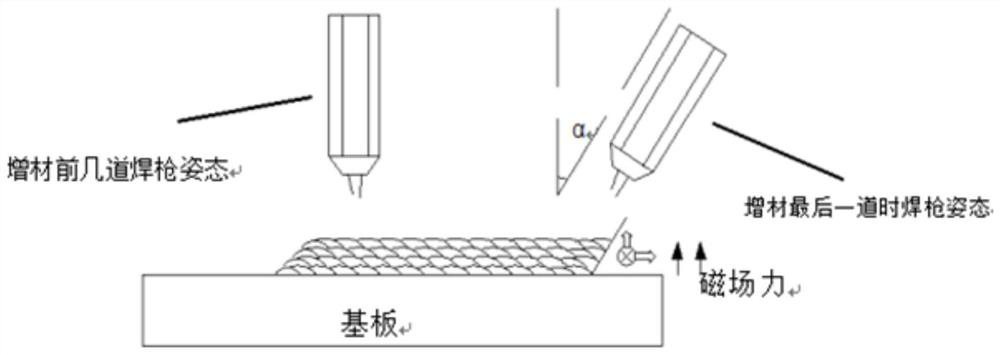

Embodiment 1

[0046] Embodiment 1: As shown in the figure, the inclined structure of the stainless steel cavity in this embodiment is a multi-layer and multi-channel structure. The height of the structure is 270 mm, the width is 60 mm, and the length is 210 mm. The angle between the structure and the substrate is 72°. The electric arc additive manufacturing power supply is FRONIUSTPS4000 GMAW power supply, the ABB robot is used as the motion mechanism, the welding machine is a CMT welding machine, and the filling wire in the forming process is 316L stainless steel wire with a diameter of 1.0mm. Arc additive manufacturing parameters: stacking speed of 4mm / s, wire feeding speed of 8m / min, stacking current of 147A, stacking process protective gas of 98.5% Ar+1.5% O 2 ,Specific steps are as follows:

[0047] Step 1: Input the preset parameters of the arc additive on the welding machine, and the controller transmits the manufacturing parameters fed back by the data processing module of the weldi...

Embodiment 2

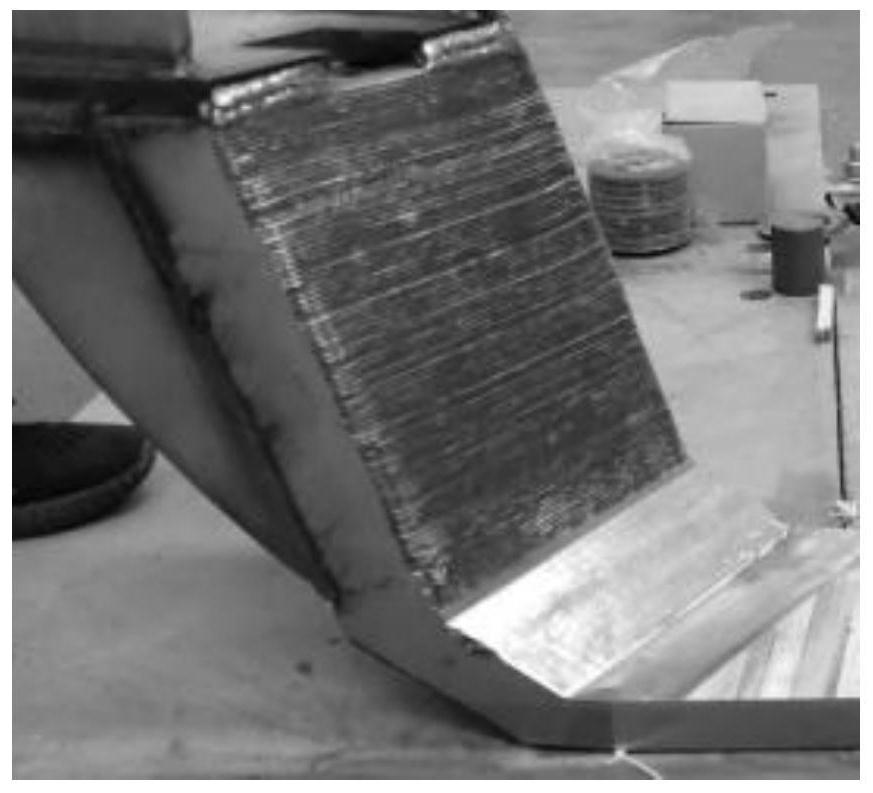

[0053] Embodiment 2: As shown in the figure, the stainless steel retracted and inclined structural member in this embodiment is a multi-layer and multi-channel structure. The height of the structural member is 80mm, the total width is 500mm, the total length is 700mm, and the angle between the structural member and the substrate is 65°. The electric arc additive manufacturing power supply is FRONIUSTPS4000 GMAW power supply, the ABB robot is used as the motion mechanism, the welding machine is a CMT welding machine, and the filling wire in the forming process is 316L stainless steel wire with a diameter of 1.0 mm. Arc additive manufacturing parameters: stacking speed is 3.9mm / s, wire feeding speed is 8m / min, stacking current is 147A, protective gas is 98.5%Ar+1.5%O2 during stacking process, the specific steps are as follows:

[0054] Step 1: Input the preset parameters of the arc additive on the welding machine, and the controller transmits the manufacturing parameters fed back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com