A method and device for three-dimensional hot bending forming of polymer pipe fittings

A three-dimensional, high-polymer technology, applied in the field of three-dimensional hot-bending forming methods and devices for high-polymer pipe fittings, can solve the problems of small size range, unstable quality, limited bending angle and bending surface of bent pipe fittings, etc. , to achieve the effects of controlling surface quality and cross-sectional shape, reducing process costs, and wide range of bending angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

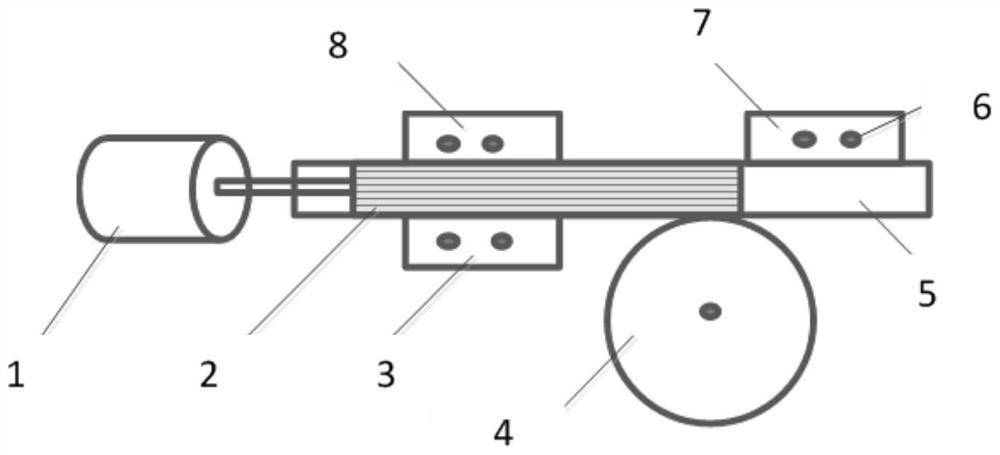

[0055]Using the method of this example to perform three-dimensional bending molding of polyetheretherketone pipe fittings with an outer diameter of 12mm and a wall thickness of 1mm, the bending radius is required to be 50mm, the bending angles are 20° and 50° respectively, and the straight line between two adjacent elbows The segment length is 10 cm. For pipe fittings with an inner diameter of ≤10mm, no soft core mold is required in the bending process. Such as figure 1 As shown, the hot bending mold device includes a space corner assembly 1, a soft polyurethane core mold 2, an anti-wrinkle mold 3, a bending mold 4, a polyetheretherketone tube 5, a heating rod 6, a clamping mold 7, and an auxiliary clamping mold 8.

[0056] (11) heat treatment

[0057] Place the polyether ether ketone straight pipe to be bent in an oil pool at 120°C, soak for 30 minutes, take out clean water and wash it.

[0058] (12) Bend the first elbow with a bending angle of 20°

[0059] First, use the...

Embodiment 2

[0065] Using the method of this embodiment to perform three-dimensional bending molding of polyetheretherketone pipe fittings with an outer diameter of 25mm and a wall thickness of 1.5mm, the bending radius is required to be 100mm, and the bending angles are 50° and 90° respectively. The straight line length is 10cm. The internal supporting soft mandrel of the pipe fitting is a polyurethane elastic soft mandrel, and the outer diameter of the soft mandrel is 21.80-21.96mm.

[0066] (11) heat treatment

[0067] Put the polyether ether ketone fittings in an oil pool at 130°C, soak for 75 minutes, take out the water and wash them.

[0068] (12) Bend the first elbow with a bending angle of 50°

[0069] First, heat the temperature of each mold with heating rod 6: anti-wrinkle mold 120°C, auxiliary clamping mold 120°C, bending mold 115°C, clamping mold 102°C;

[0070] Then pass the polyether ether ketone straight pipe 5 to be bent through the soft mandrel 2 and place it in the gro...

Embodiment 3

[0075] Using the method of this embodiment to carry out three-dimensional bending molding of polyetheretherketone pipe fittings with an outer diameter of 38mm and a wall thickness of 1.5mm, the bending radius is required to be 152mm, and the bending angles are 20° and 50° respectively. The straight line length is 10cm. The internal supporting soft mandrel of the pipe fitting is a polyurethane elastic soft mandrel with an outer diameter of 34.80-34.96 mm.

[0076] (11) heat treatment

[0077] Put the polyether ether ketone pipe fittings in an oil pool at 140°C, soak for 120 minutes, take out clean water and wash them.

[0078] (12) Bend the first elbow with a bending angle of 20°

[0079] First, use the heating rod 6 to heat the temperature of each mold: the anti-wrinkle mold is 125°C, the auxiliary clamping mold is 130°C, the bending mold is 120°C, and the clamping mold is 125°C;

[0080] Then pass the polyether ether ketone straight pipe 5 to be bent through the soft mandr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com