3D printing forming method of composite material

A composite material and 3D printing technology, applied in the field of composite material manufacturing, can solve the problems of over-melting evaporation, large difference in melting point, failure of diamond to melt, etc., and achieve the effect of improving printing efficiency and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

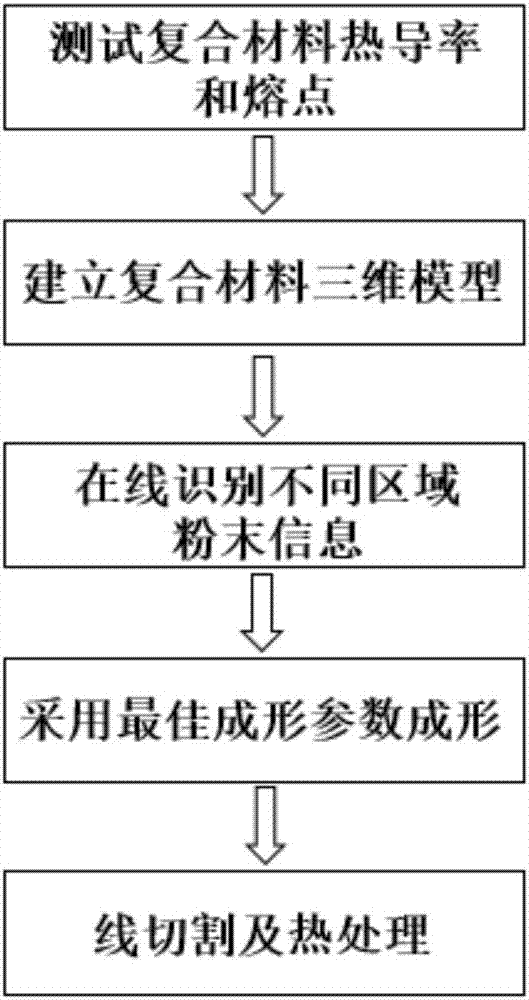

[0018] A composite material 3D printing forming method, comprising the following steps:

[0019] (1), respectively carry out the test of thermal conductivity, melting point to Fe and C in Fe / C composite material, and input the test result in the computer database of 3D printing equipment, described Fe powder and C powder are spherical or Nearly spherical, the average particle size of both is distributed between 20-45μm and the oxygen content is lower than 1000ppm;

[0020] (2), design the three-dimensional model of the composite material part by CAD software, then convert the three-dimensional model of the part into an STL file format and import it into the computer of the 3D printing device;

[0021] (3) Spread the Fe powder and C powder evenly on the powder bed according to the ratio requirements of the composite material, turn on the infrared detector, identify the material components in different regions of the composite material online, and feed back the recognition resul...

Embodiment 2

[0027] A composite material 3D printing forming method, comprising the following steps:

[0028] (1), respectively carry out the test of thermal conductivity, melting point to W and Cu in W / Cu composite material, and input the test result in the computer database of 3D printing equipment, described W powder and Cu powder are spherical or Nearly spherical, the average particle size of both is distributed between 20-45μm and the oxygen content is lower than 1000ppm;

[0029] (2), design the three-dimensional model of the composite material part by CAD software, then convert the three-dimensional model of the part into an STL file format and import it into the computer of the 3D printing device;

[0030] (3) Spread the W powder and Cu powder evenly on the powder bed according to the ratio of the composite material, turn on the infrared detector, identify the material components in different regions of the composite material online, and feed back the recognition results to the com...

Embodiment 3

[0036] A composite material 3D printing forming method, comprising the following steps:

[0037] (1), carry out the test of thermal conductivity, melting point to Al and SiC in Al / SiC composite material respectively, and input the test result in the computer database of 3D printing equipment, described Al powder and SiC powder are spherical or Nearly spherical, the average particle size of both is distributed between 20-45μm and the oxygen content is lower than 1000ppm;

[0038] (2), design the three-dimensional model of the composite material part by CAD software, then convert the three-dimensional model of the part into an STL file format and import it into the computer of the 3D printing device;

[0039] (3) Spread the Al powder and SiC powder evenly on the powder bed according to the ratio requirements of the composite material, turn on the infrared detector, identify the material components in different regions of the composite material online, and feed back the recogniti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com