Rolling pin grinding device

A rolling pin and drive shaft technology, which can be applied to grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of low rolling pin efficiency and uneven grinding shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

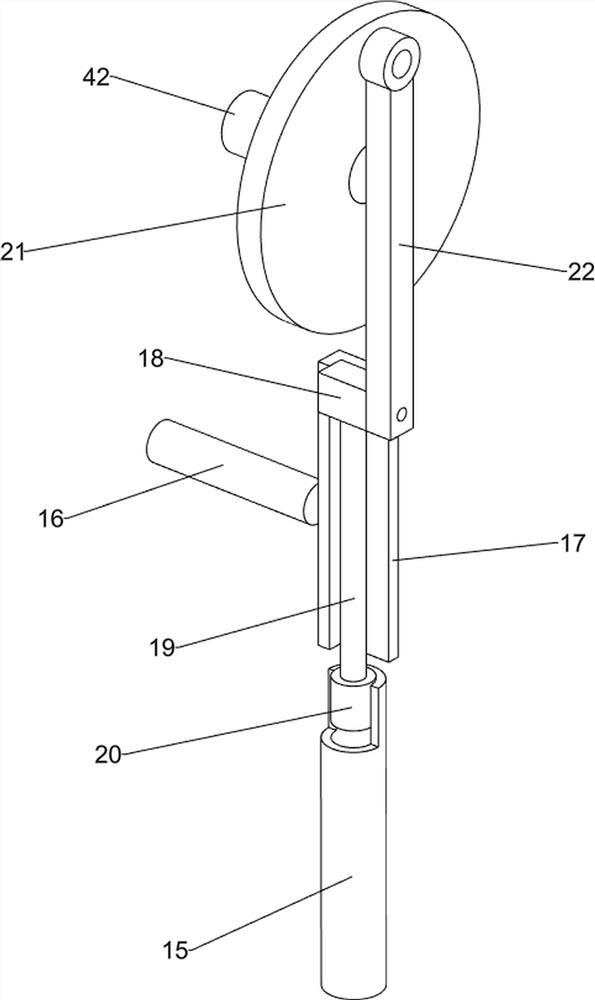

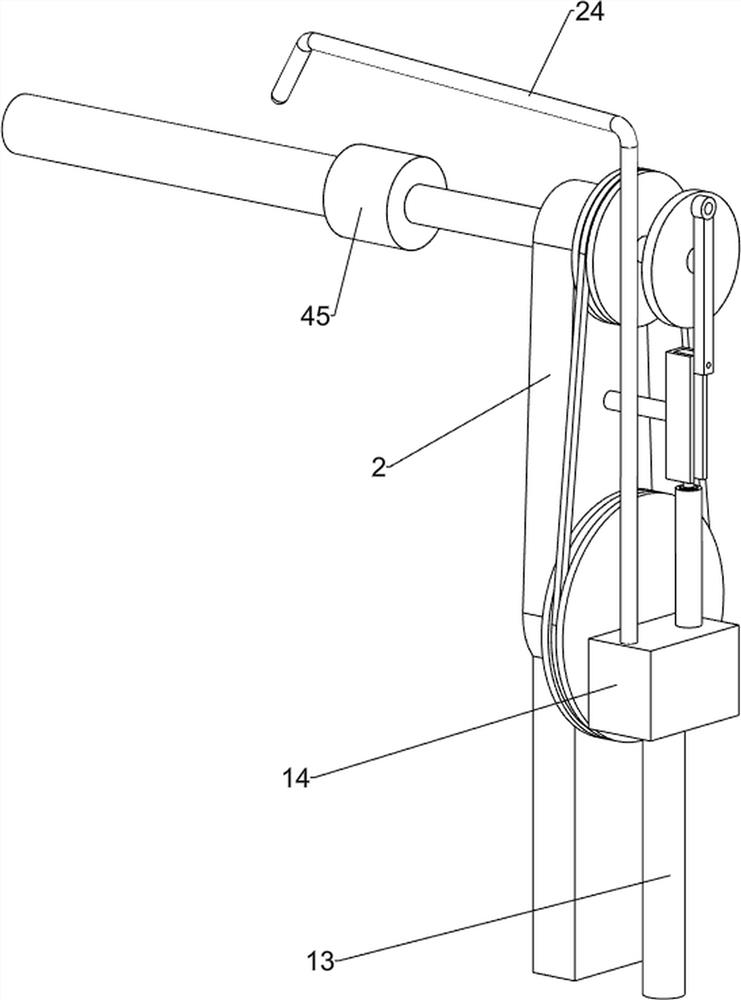

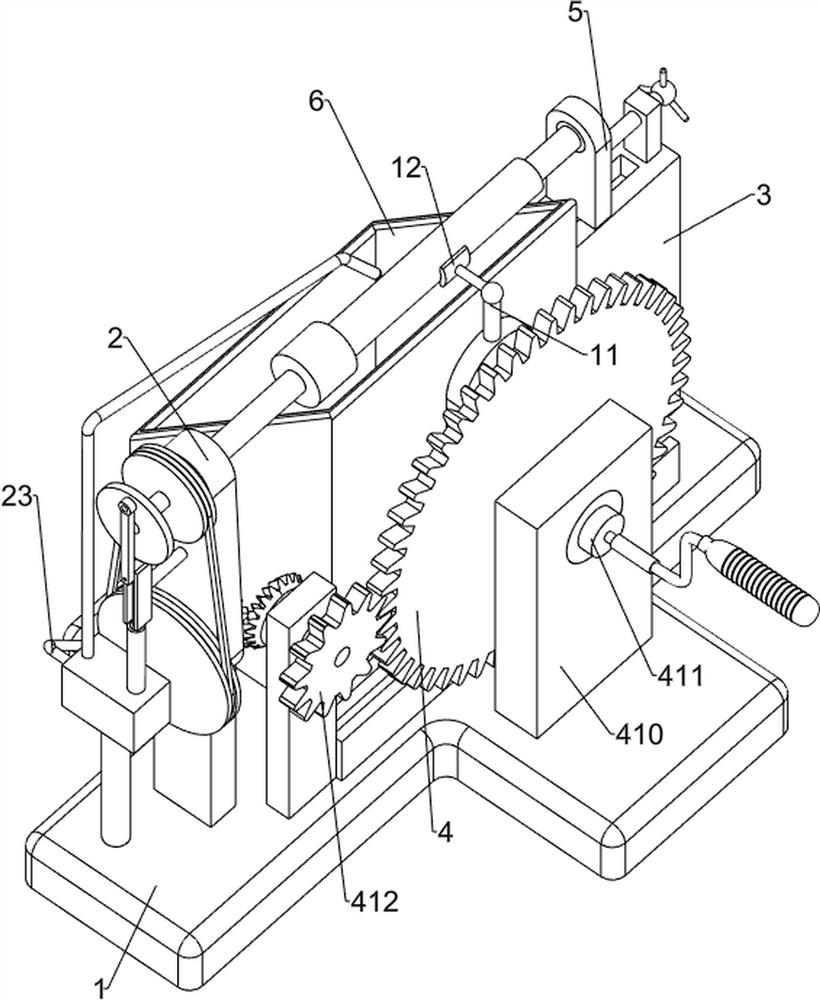

[0021] Such as Figure 1-2 As shown, a rolling pin grinding device includes a base 1, a bracket 2, a cushion block 3, a rotating mechanism 4, a clamping mechanism 5 and a water tank 6, the left side of the top of the base 1 is provided with a bracket 2, and the right side of the top of the base 1 is provided with a Block 3, a rotation mechanism 4 is provided on the top middle side of the base 1, a clamping mechanism 5 is provided on the upper end of the block 3, the clamping mechanism 5 cooperates with the rotation mechanism 4, a water tank 6 is provided on the top middle side of the base 1, and the water tank 6 Located between pad 3 and bracket 2.

[0022] When people need to polish the rolling pin, put the rolling pin between the clamping mechanism 5 and the rotating mechanism 4, the clamping mechanism 5 fixes the rolling pin, then people rotate the rotating mechanism 4, and the rotating mechanism 4 rotates to drive the rolling pin to rotate, and people can now The rolling ...

Embodiment 2

[0028] Such as Figure 3-4 As shown, on the basis of Embodiment 1, a rolling pin grinding device also includes a first slide rail 7, a second slide block 8, a return-shaped groove plate 9, a guide post 10, a first support post 11 and a friction block 12. The first slide rail 7 is set in the middle of the top of the base 1, and the second slide block 8 is set in the sliding type inside the first slide rail 7. The second slide block 8 is provided with a return-shaped groove plate 9, and the rear side wall of the large gear 413 The position is eccentrically provided with a guide post 10, the guide post 10 is slidingly matched with the return-shaped groove plate 9, the upper end of the return-shaped groove plate 9 is provided with a first support column 11, and a friction block 12 is arranged on the first support column 11.

[0029] In order to polish the rolling pin more evenly, when people turn the handle 414, the large gear 413 rotates to drive the guide post 10 to rotate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com