Three-degree-of-freedom pneumatic flexible driver with variable rigidity and preparation method thereof

A flexible drive and drive technology, which is applied in the direction of manufacturing tools, program-controlled manipulators, and modification with liquid cooling, can solve the problems of poor load-carrying capacity of the drive and low response rate of stiffness adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

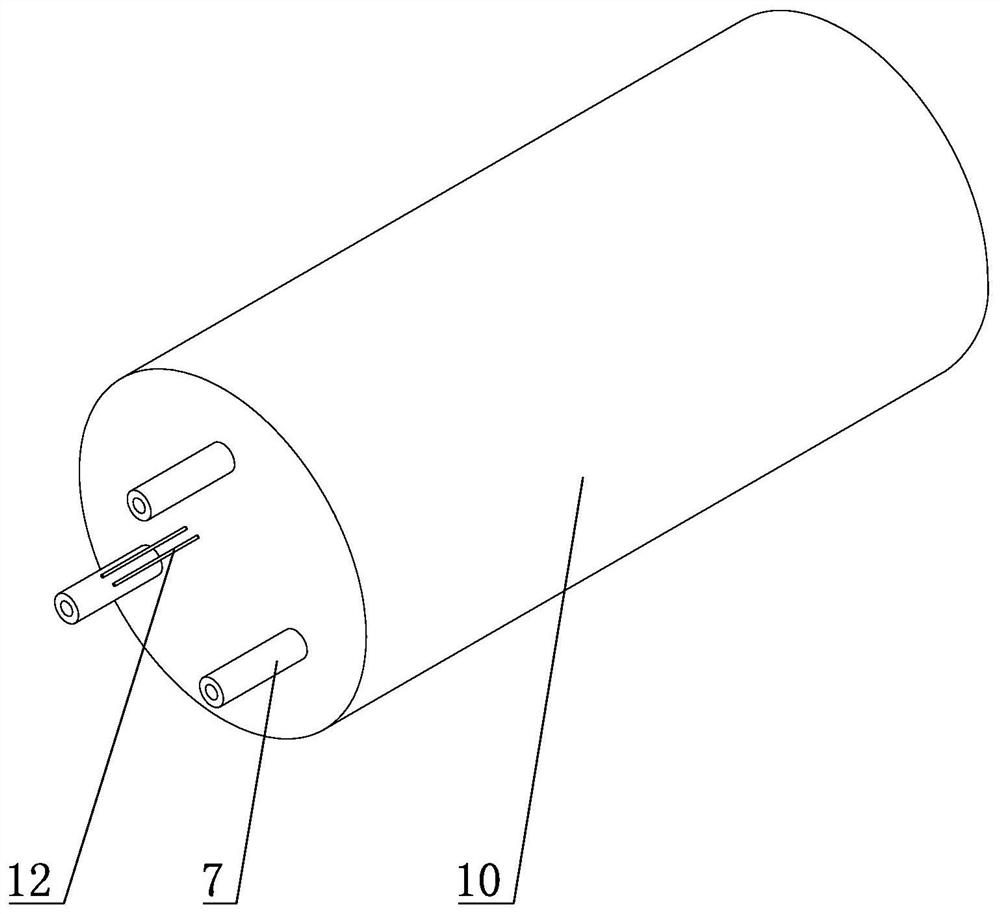

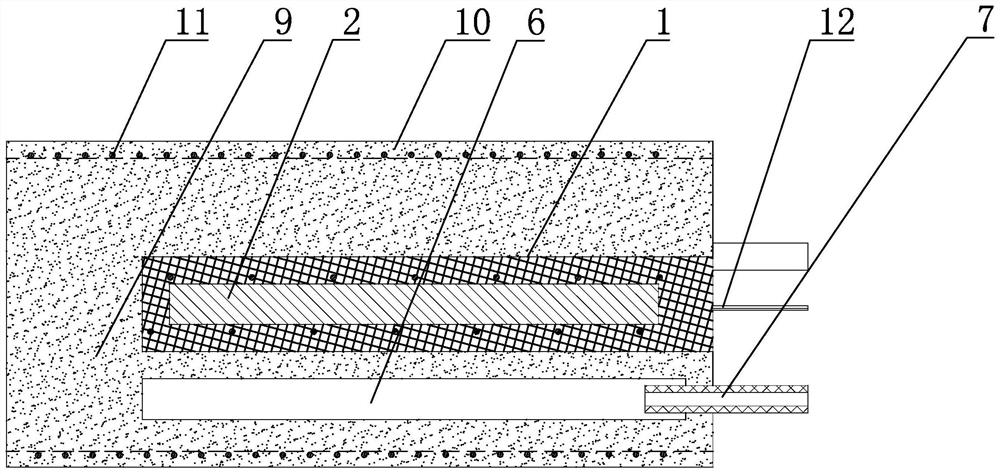

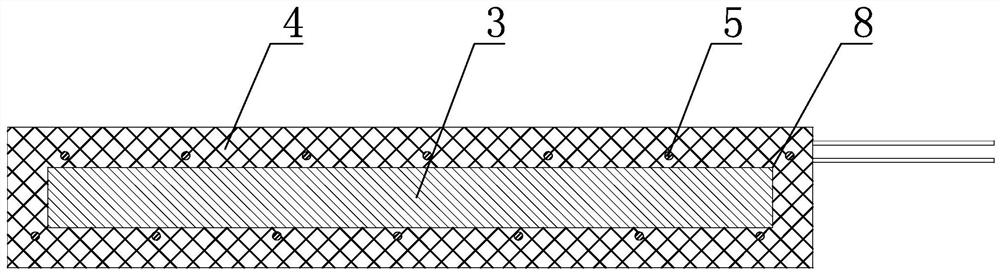

[0033] Such as Figure 1 to Figure 3 As shown, a variable stiffness three-degree-of-freedom pneumatic flexible driver includes a driver body. One end of the driver body is provided with a mounting groove 1 arranged along its length direction, and a variable stiffness module 2 is embedded in the mounting groove. The variable stiffness module includes The liquid metal 3, the protective shell 4 and the heating element 5, the liquid metal is packaged inside the protective shell, several air cavities 6 are opened inside the driver body, the air cavities are arranged along the length direction of the driver body, and the gas pipe 7 inserted on the driver body One end of the air pipe communicates with the air cavity, and the other end of the air pipe extends to the outside of the driver body; the axis of the installation groove is arranged obliquely to the axis of the driver body, and the center of the opening end of the installation groove is on the axis of the driver body. The inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com